Job Candidate Questions and What They Tell Us

Individuals who ask thoughtful, original questions in the interview set themselves apart.

#columns #workforcedevelopment

Shop and School Symbiosis

PMPA member Clippard Instrument Laboratory has been working with Butler Tech for over 45 years and the benefits keep growing.

#pmpa

Buy a Solution, Not a Machine

INDEX collaborates with customers to find a total solution to meet their needs.

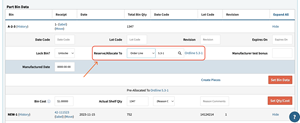

.1692282151847.png;maxWidth=300;quality=70)