A Formula for Cutting Tool Success

The hardness and toughness of a tool are generally counteractive forces, and finding the right mix can be a challenge. Wouldn’t it be nice to have both?

As any shop knows, not much metalcutting can happen without the cutting tool. But what is it that makes one cutting tool different from another—better for a specific application? Much of that can be seen in the manufacturing process of the carbide blank itself.

It starts with a mixture of tungsten and cobalt (the binder that holds the various ingredients together). But the final result can include one of any number of variations in carbide grain size (affecting sharpness of the cutting edge) and ratio of carbide to binder. Each of these combinations is engineered for real-world applications involving different cutting operations, cutting depths and widths, and associated workpiece materials. The goal is to produce the best blend of hardness and toughness (each increases as the other decreases) to provide the longest tool life and most effective cutting ability for a given application.

Featured Content

Once the ingredients are mixed, different processes can be used to shape the substrate. Basic shapes are often ground on a manual grinder while more complex geometries may be ground on a CNC grinder or even an EDM, depending on the design. Finally, to enhance cutting performance and tool life, the substrate is often coated with various chemical mixtures via physical vapor deposition (PVD) or chemical vapor deposition (CVD).

A Supplier’s Story

Carbide cutting tools typically have between 2 and 15 percent cobalt content for binding. The higher the percentage, the less carbide, and therefore, the softer and less rigid the tool. But a certain amount of cobalt is needed to hold the carbide ingredients together and minimize the brittleness.

When carbide rod is supplied to a cutting tool manufacturer, it has a specified percentage of cobalt, but that cobalt is scattered throughout the substrate, often inconsistently, so some areas of the rod have voids or air pockets and, therefore, can be weaker than others. To compensate for these inconsistencies, higher percentages of cobalt can be used, yet even this strategy is not foolproof.

Almost 50 years ago, Jack Newberry, a machinist by trade, invented a new process for carbide cutting tool development. This process, which, to this day remains a company secret at Micro 100, aligns the cobalt binder in a consistent percentage throughout the structure of the rod, and eventually the cutting tool itself. This capability allows the tool to attain a perfectly homogenized substrate, end to end, therein having no air pockets or voids, thus preventing heat and vibration from being able to penetrate the tool. The result, according to Micro 100, is the ability to maintain a sharper edge and longer tool life.

According to Charlie Mersinas, Micro 100 regional sales manager, the tools have a TRS (transverse rupture strength) similar to high speed steel, which has far more flex than that of “normal” carbide, yet is not brittle and maintains superior toughness. “High speed steel will move around a little bit while cutting, but is not as strong as carbide and will dull more quickly. Then you can’t cut as much material,” he says. “Carbide is rigid and very hard anyway, so it will cut through anything. But once we put our substrate through our proprietary process, we take the brittleness out, and the rigidity is maintained throughout the tool.”

Spreading the Word

Mr. Mersinas says he likes to present the tools to customers in a way that demonstrates the number of tools required per job. He feels that if he can get the tool on the spindle making parts and show that it can provide longer tool life, it’ll be hard to say no.

The savings is two-fold. The first layer is more obvious: Any time a machine isn’t making parts, it’s costing money, so the longer the tool lasts, the less downtime there is changing it out. But Mr. Mersinas explains that the second form of savings often is a pleasant surprise to customers. Because the substrate is the same consistency from tool to tool, parts come out with consistent finishes and tool life is far more predictable. If the substrate’s molecular structure is weaker in one area than another (which is often the case), tools are going to chip or break early. One tool may produce 15 parts when another might only produce two, depending on when the weak part of the tool is engaged in the workpiece. Consistency allows for better job scheduling and fewer bad parts being produced, therefore increasing the consumer’s shop efficiency and workflow. It lowers scrap while enhancing profits.

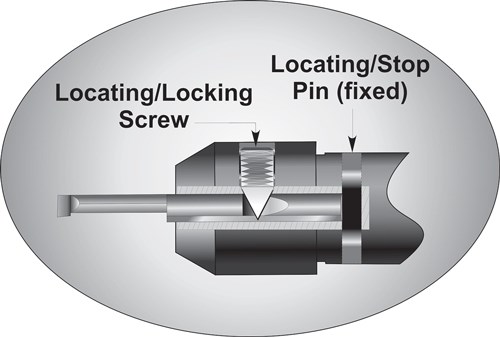

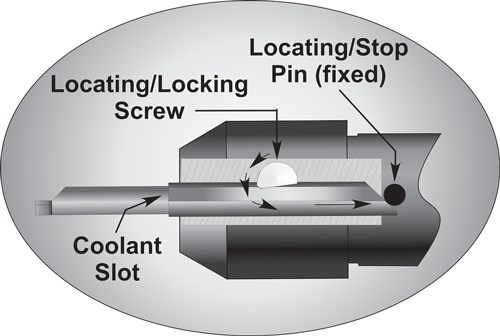

Micro 100, perhaps better known for turning because of the company’s solid carbide boring bars, also has a line of milling and brazed tools that feature the same consistent performance. The design correlates well with its quick-change toolholder line (Micro-Quik), which the company developed in 2009. These toolholders and bars feature repeatability within 0.0005 inch from tool to tool, with tool change in 30 seconds or less. Mr. Mersinas says, “When working with tight tolerances, these toolholders can save the operator from needing to reset the cutting tool each time, making sure it’s on the zero axis, and then set the tool to make sure it repeats from centerline to centerline. Once our toolholder is set, if a tool is dull, the operator can unscrew the screw, put in a fresh tool, and hit start again to begin cutting more parts, still within the tight specified tolerance.”

A Customer’s Story

In 1972, Joe Cassavant Sr. started Cassavant Machining Inc. (CMI) in his garage, with a single manual lathe, doing overflow work for other local shops. Since then, the company has grown to employ more than 150 people and houses more than 80 CNC machines in its 55,000-square-foot Phoenix, Arizona, headquarters. The company has 14 Star CNC Swiss screw machines (16, 22 and 32 mm), 32 Mazak CNC lathes, and 36 Mazak three-, four- and five-axis CNC mills.

CMI focuses primarily on high precision work for the aerospace, military and medical industries, producing parts in aluminum bar and stainless steel as well as more difficult materials such as Inconel, Hastelloy and other aircraft alloys. The cyclical nature of these industries has taught the company to be careful in maintaining fiscal responsibility. All equipment is paid for up front, without relying on credit to pay for day-to-day operations.

This same attention to the bottom line carries over to CMI’s choice in tooling, as it selects the tools it feels delivers the best bang for its buck. “We might not buy the least expensive tools off the shelf,” says Joe Cassavant Jr., company general manager. “But if they deliver longer tool life, and we can make more parts and have less downtime, the price difference can be easily justified.” He says the company first learned about Micro 100 tooling at a Westec show more than 15 years ago, observing the representative drop a boring bar onto a piece of steel from about 4 feet off the ground with no ill effects such as chipping. They were impressed enough to give the tooling a try and have continued to use it ever since in almost all applications.

Through those years, CMI has developed a strong relationship with Micro 100. Joe Jr. says his company was involved in beta testing during the design stages of the Micro-Quik product and was able to offer suggestions along the way for features of the product that could help make it more efficient. That product alone has had an important impact for CMI. “Typically with the Swiss machines, when you have to change your bar, you have to re-center your tools, but with Micro-Quik, the tool just goes back in, ready to go,” Joe Jr. says. “The three-point locking mechanism, providing repeatability within 0.0005 inch, saves a lot of time in changing the bars out.” He believes this system gives them a 10- to 12-percent increase in production because of reduced setup and replacement times, along with significant cost savings because of the longevity of the tooling.

CMI uses Micro 100 tooling throughout its milling department as well. Micro 100 maintains an exclusive private-label venture with Wohlhaupter on certain aspects/designs of its system, and CMI uses these digital boring heads, saving a lot of time in milling operations, according to Joe Jr. “We’ve used other boring heads that just weren’t as accurate, and we’d end up losing stock, and we’d need another operation to finish parts,” he says. Now all operations can be complete in a single setup, so the savings are easily realized.

As a final quality assurance, CMI has a rather large inspection department for confirming part requirements. Anything 0.002 inch or less can be checked 100 percent. These tighter tolerances are usually the most important, functional features of the part, so it’s critical that these specs are met. Because the company has had such success with tooling durability, it is able to get the quality and repeatability it needs. “We’ve used other tools in the past that would wear out quickly and chip, not giving the finishes that we get now. The dimensions would change because the tool was always wearing,” Joe Jr. says.

He recommends that shops consider bringing in Micro 100’s application engineers to evaluate the work being done and to see how the tooling may help. “They know what should work best based on materials, features to be cut, feeds and speeds. They should have a solution that can have a big impact on a shop’s productivity.”

RELATED CONTENT

-

Selecting the Right Milling Tool for Any Machining Task

High-performance milling cutters combine high cutting data with long tool life and efficiency, but certain factors must be considered when selecting tools for different machining tasks.

-

Cutting Tool Coating Production

This article looks at the coating methods available for carbide cutting tools.

-

The Ins and Outs of Inserts

Understanding how inserts are made provides valuable insight into how their performance can be optimized.