March 2007 ISSUE

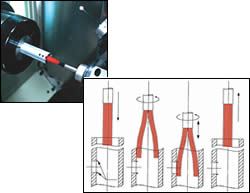

Ceramic Fibers For Precision Deburring

Removing burrs from precision machined parts is the bane of every metalworking shop. These pesky residuals add to the cost and complexity to most production processes. Moreover, most customers for precision parts mandate a zero-tolerance policy for burrs.

FEATURES

Ceramic Fibers For Precision Deburring

Removing burrs from precision machined parts is the bane of every metalworking shop. These pesky residuals add to the cost and complexity to most production processes. Moreover, most customers for precision parts mandate a zero-tolerance policy for burrs.

Efficient Operation With High-Pressure Coolant

Manufacturers spend millions of dollars on liquid coolants each year to help machine tools cut metal more efficiently. In many cases, however, the effect of this coolant could be greatly enhanced—in some applications by 100 percent or more—by using a high-pressure coolant delivery system.

Member Profile: Allied Machined Products

Allied Machined Products is a family-owned-and-operated manufacturer of precision machined parts. The company was founded in 1946 in Worcester, Massachusetts, by Louis Weber, who retired in 1965. He was succeeded as president by his son Russell Weber who, in turn, was succeeded in

1987 by his son, current president Peter Weber.

CAD/CAM

Optimizing Cycle Times With CAM

Swiss-type lathes and CNC automatic screw machines now have more power and flexibility and better accuracy than ever. As the popularity of CNC continues to grow on these machines, a good computer-aided manufacturing (CAM) system is increasingly necessary to take full advantage of the machines’ true multitasking capabilities.

PMPA Education Foundation

In 1999, the PMPA Board of Trustees established the PMPA Education Foundation to "ensure the future success of our industry by supporting educational research and related projects."

Turning Machines

Swiss Precision And Flexibility Help Shop Compete

This company is so pleased with its new Swiss-type turning center's performance that the company president calls it "the best possible way to keep this work in the United States." As his research indicated, the machine reduces labor costs by completing four or more machining operations in a single setup

Industries

Want To Do Medical Work? Set Up To Perform

This Midwest manufacturer has found its niche in machining parts for the medical industry. Much of its success is attributable to its efficient use of single-spindle CNC turning centers. However, the company prefers to talk about what happens when the tool touches the metal, and let the results speak for themselves.

Chris Felix: Reaching Out

Anthony E. Reiss: Why Talk About Money?

Mary Beth Holley: Taking Charge Of Energy Costs

Mitch Free : ISO Certification

Chris Koepfer: Let Go And Keep Going

PM News: Sandvik To Acquire U.S. Producer Of Diamond-Based Materials