Automate Programming with CAM

Even for those shops still manually programming their simple parts on Swiss machines, there are compelling reasons to automate the programming process now.

Dedicated Swiss shops and those performing mostly turning operations in general, have been slower to jump on the CAD/CAM bandwagon than those requiring additional cutting operations such as milling. The reason is simple. Many turned parts are less complex than those that require simultaneous five-axis contoured surfaces and a high level of mathematical computations to create the machine tool’s G code.

Further, many of these manual programmers have been doing it for a decade or two and are experts at programming. They can visualize the sequences in their “mind’s eye” and synchronize all the operations on the main spindle, the subspindle and the turret. Or, they may have become proficient at dry cycling through the program to watch for problems.

Featured Content

For complex turning operations that are not parallel or perpendicular to the part, these programmers sometimes “pull the points” from a CAD program. If they have a bit of milling to do, they might use a CAM program just for those one or two toolpaths and cut and paste those toolpaths into their code. Although this gets the job done, the effort to make it happen and the ease with which it happens varies greatly from shop to shop and part to part. It’s usually not as simple as “cut and paste.”

As any savvy shop owner knows, it’s prudent to always look at what new opportunities could currently be leveraged and what new technology is available to support the longevity of the business. He doesn’t want to get left behind like many of the shops in the 80s that never decided to upgrade to new technology. One idea is to revisit the notion of automating the programming process.

The Advent of Full Five-Axis Swiss Machines

Over the last decade, we have witnessed the steady advance of more complex tooling solutions becoming available on Swiss-type machines. The latest pinnacle of this advancement has been the addition of full five-axis motion on Swiss machines. Many engineers are taking a fresh view at parts that previously had to be done in multiple operations, for example, perhaps taken off the turning machine and processed on a mill.

Also, some new part designs are requiring five axes, especially in the dental and orthopedic industries. Imagine the contours of a dental crown. Then imagine trying to manually figure that math. That’s when the benefits of a comprehensive CAM package become obvious and necessary. It is also the reason some shops can’t bid on more complex jobs. They aren’t equipped to compete at that level.

However, the situation doesn’t need to be the most sophisticated case for CAM’s benefits to save the day, for example, if the project calls for a simple 2D slot with a break edge on it, or some face milling requires G12.1. Even the most adept manual NC programmer would agree that a project requiring three or more axes demands a more automated programming approach. It also makes sense to get beyond cutting and pasting the complex toolpaths into the code, or merely grabbing points from the CAD file, and take full advantage of the whole package. Many of those elements will be described in this article.

Attract the Best and Brightest

The fact that there is a shortage in manufacturing of skilled machinists including manual NC programmers is not news, but it is of concern. The reason that point is a compelling one relevant to CAM is because new workers will not only need it because of their inexperience in manual programming, but they also will want it. Shops that have the latest computerized “toys” could very well win over the bright people with promise into the business.

Further, introducing more automation could serve to retain the younger and young-at-heart workers currently employed at the shop, creating an atmosphere of engagement and encouragement to keep learning and growing into their potential. Interviewers need to be prepared to answer questions from today’s applicants about the software and advanced manufacturing technology the shop will provide for them to succeed at the job.

Competitive Bidding

The ability to preview the machining process and resulting cycle times off -line for the purpose of quoting a job or similar jobs much more accurately is another benefit of creating NC programs in a comprehensive CAM software package. Quoting projects correctly can help keep current customers and attract new ones, plus maintain or increase profit margins. It also gives the engineer the opportunity to discover the areas that may be problematic, and start the conversation early on with the customer with recommendations about how to handle certain parts of the machining process. Customers appreciate that level of knowledge and proactive resolution for potential issues.

This isn’t Your 70s ‘Solid’

The solid model is becoming the standard form that customers supply to their vendors. When a shop received a customer’s order 25 years ago, it was accompanied by a 2D print. That evolved into a wireframe in a 3D space, but still predominantly wireframe. Then surfaces became the usual form, which is still widely used.

However, now with SolidWorks, ProE, CATIA, and other CAD programs, solid model files are emerging as the preferred format for work coming into a shop. The solid model is where all the dimensional accuracy is contained, and the solid can be imported seamlessly in the CAM software. The geometry for the toolpaths can be taken directly off the solid model, creating the part exactly how the design engineer envisioned it. With CAM, there is no redrawing and no re-inputting dimensions with the grave possibility of inputting errors. The efficiency of this workflow procedure is so smart and simple that it seems terribly wasteful to function otherwise.

Simulation Stimulation

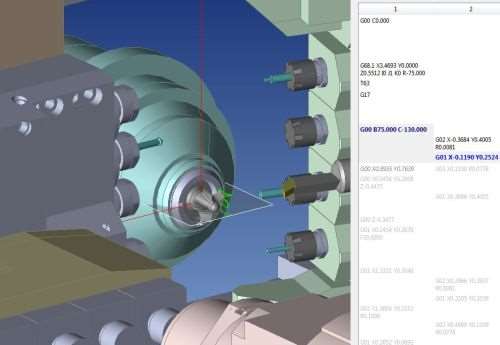

Visual simulation in the CAM programs has advanced greatly over the past decade thanks to more powerful computers, user-friendly software interfaces, and more realistic 3D graphical representation of all of the elements of the process—machine, fixture, spindles, turrets, cutting tools and workpieces. Simulation could be described as automation within the automation of NC programs, and the benefits are almost too numerous to list, especially for complex mill-turns and Swiss-type machines with their small work envelope tightly packed with tools and possibly a programmable B axis. In other words, this is equipment with a lot of moving parts that can hit into each other.

The main benefits of simulation include collision detection—ensure components (part, tool, fixture, machine) do not crash; prove out toolpaths before actual machining; calculate machine cycle times; and refine the process to improve productivity, such as opportunities to resynchronize to take advantage of wait time.

The ultimate benefit to all of the above is the elimination of scrapped workpieces, wasted time making bad parts, and collision damage to fixtures, cutting tools and machines. Plus, there’s just something cool about watching the NC program unfold on a machine tool as it will look when it’s run without the mess or inconvenience of coolant blocking the view.

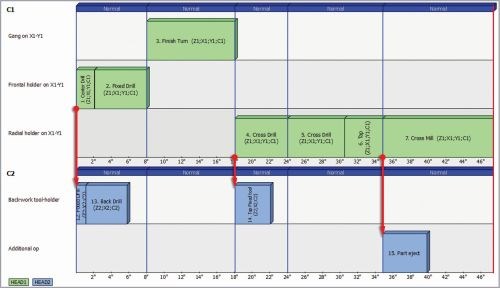

Synchronization Symphony

CAM packages allow the user to synchronize multiple operations quickly and easily. The resulting view of the sync points or superimposed operations are clear and simple to interpret, giving the user an overview of the entire process. Mastercam Swiss Expert uses a Gantt-style method to accomplish this. The user can drag and drop sync points with a click of the mouse. There are highly experienced and skilled workers who can “see” the synchronization in their heads as they look down the lines of code.

This is reasonable to do on a simple gang-style lathe, but add a turret with a Z axis into the mix and suddenly it gets a lot more complicated to visualize the timing, especially if two tools are cutting simultaneously. Others, and surely anyone new coming into the industry, need a visual tool to review how all the moving parts work together like a symphony of machining operations. Automating the NC programming process and acquiring a CAM package that has a strong process synchronization capability to gain this one important advantage may be worth it.

Shop Yoga

Many shops in the Swiss machining segment of the industry are known for producing millions of the same part. Even so, there’s something to be said for working in more flexibility into the operation to accommodate the occasional short run jobs that require speedy change-overs. Having CAM software in-house with a proficient programmer expedites those types of jobs. Once a process has been perfected, any part of it (including speeds and feeds and nuances of the toolpath motion) can be easily imported into future jobs. Also, since there’s never a

guarantee that those long run projects will last forever, instituting more flexibility can help attract different and new customers whose needs may fall into the short run, fast turnaround category. CAM can help stretch the shop’s versatility and agility to respond to needs that could be unknown and interesting.

To prepare to introduce CAM into the shop’s operations, a great place to start learning CAM is with those high production jobs that the shop has produced for a long time. They offer the programmer the opportunity to learn the software using a familiar process, with the same tooling and proven NC code. It’s also an opportune way to get the post dialed-in on a known process and output.

Paper Trail

A sometimes overlooked, yet powerful, plus of CAM software is the documentation the program can generate. This feature takes whatever information is within the project and creates different ways of reporting it, such as the list of tooling used, process details, screen shot images of the raw stock, what the part looks like after the first toolpath, speeds and feeds, cycle times, notes relevant to the job, and more, all in a printable format.

The documentation can be useful to machine operators and setup people who need to identify coordinates and fixture designers—virtually anyone who touches the project in some way. The document can also be filed for easy reference when the job repeats or a new, similar job comes in. It is a handy visual reminder of what the job entails. It also establishes a consistent format for record keeping, making it easier to find information quickly once the staff becomes familiar with how all the aspects are presented in the layout.

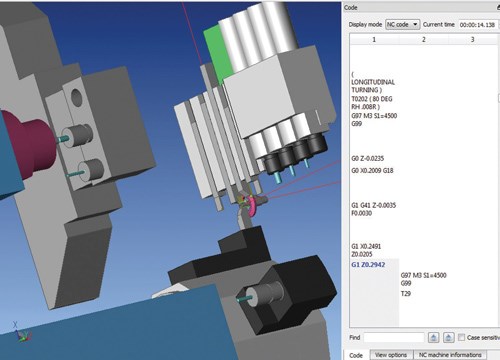

Like Spell Check for NC Code

Transfer and review the actual NC code in the software program’s “editor” is an important last step before uploading a CAM project to the CNC machine. If there might be a main spindle, subspindle and/or turret in play, most times each is driven by its own program. In editor mode, the code for each of those components is presented side by side with the synchronization points aligned and highlighted for the person to review and consider.

Are these the correct points? If not, the programmer goes back into software, makes the corrections and verifies it in the Gantt chart or in simulation, or both. The ability to see the code in simulation is very helpful. Then he or she reposts it to the editor for a second look. If the change is simple, such as a feed or speed, that may be done right in the editor. The editor to a CNC file is similar to spell check in a written document, and it’s the last step before submitting. The editor is important as part of a prudent workflow procedure that is available as a stand-alone product for those still manually programming.

Get your CAM On

It’s clear that, particularly in the more traditional Swiss-type shops primarily doing long runs of simple parts, CAM may not necessarily be the answer or make a huge impact in the shop’s business. However, even for this type of business model, CAM can certainly offer more flexibility to perhaps win more complex, short-run work. It can help to ease the transition from those wonderfully skilled employees who are “short timers,” whose experience cannot be taught to new people poised to step in their steel-toed boots. It permits a platform for the younger generation to learn from the more experienced generation off-line, without impeding the machine’s uptime. CAM allows more efficient workflow procedures with increasing solid model CAD files flowing in with job orders. It is an accurate way to quote new jobs, too. Consistent code being produced eliminates programming “style” issues that surface from programmer to programmer. CAM makes it easier to set code standards, simplifying processes for the machine operators. CAM can allow a shop to consider putting the most advanced five-axis mill-turns or the newest Swiss-types with a B axis on the gang slide on the floor, knowing the most efficient and accurate way to program these crazy machines is ready, willing and able to make them hum as intended.

RELATED CONTENT

-

Keeping Watch on Small Parts

From watch parts to exotic medical applications, this shop takes on the world of micromachining.

-

Consider the Software Side of Cutting Tools

The intersection of the cutting tool and the workpiece it is applied to represents the very heart of subtractive metalworking. There is a significant amount of technology behind getting the cutting tool into the right place, at the right speed and the correct depth of cut. This article looks at some of the software technology that can optimize the performance of the cutting tool.

-

VIDEOS: Tips for Screw Making on Swiss-Type Machines

Here’s a three-part video series focused on Swiss screw making to help explain the benefits of thread whirling, back turning and broaching while taking into consideration CAM programming, tooling and machine specifications.