Band Saw Technology Takes A Leap

New technology in the form of coatings and tooth geometry are making sawing a potential source of efficiency in a shop.

The last giant leap in band saw blade technology happened in the mid 1960s with the establishment of bi-metal technology, which was soon followed by the introduction of carbide-tipped blades.

Band sawing efficiency was limited prior to the advent of bi-metal blades. The band saw blade used to be made entirely of high carbon steel because it was pliable enough to withstand the stress caused by its winding path around the band saw machine’s drive wheels and through the saw blade guides. Because it was necessary to use a softer, more flexible backing material, manufacturers were prevented from capitalizing on the sawing efficiency that could be gained by using a harder material that would provide a more durable tooth edge.

Featured Content

Bi-metal and carbide-tipped band saw blades changed band sawing tremendously and permanently. Since then, advancements in tooth configurations, tooth geometry, edge materials and backing steels, in addition to improved methods for welding carbide-tipped teeth, have continued the band saw blade’s march toward increased productivity and blade life at a relatively steady pace.

Recent developments in second generation physical vapor deposition (PVD) coatings and tooth design constitute the latest big jump in band sawing, such as the one experienced with the introduction of bi-metal and carbide-tipped blades.

Second Generation Coatings

After being used on smaller cutting tools, such as drills, inserts and end mills for many years, coatings made their first marginally successful appearance in the band saw blade industry in the early 1990s. These first mono-block titanium nitride (TiN) coated blades were expensive and plagued by inconsistent manufacturing. Now, second generation coatings enable higher speeds and feed rates by making the tooth edge harder and tougher, protecting it from excessive abrasion and heat. Applying protective coatings to a band saw blade provides a demonstrable increase in productivity without decreasing blade life. These coatings are the next step of improvements that the band saw marketplace has been demanding—coated carbide for increased feed rate and coated bi-metal for improved blade life.

The last few years have seen blade manufacturers taking steps toward the mastery of the various processes (chemistry, material preparation, application technique and fixturing) necessary to apply coatings to larger cutting tools such as band saw blades. As manufacturers have improved their methods of applying coatings, coated blades have steadily gained industry acceptance, especially in high-production shops.

Manufacturers now offer a variety of blades with advanced, application-specific coatings such as titanium nitride (TiN) and aluminum titanium nitride (AlTiN) that deliver previously unheard of productivity and increased life.

Coated bi-metal blades combine the benefits of bi-metal with those of coatings, offering high sawing and feed rates in addition to increased blade life.

Band saw blade manufacturers are currently researching and developing the coatings of tomorrow. Nano-composite third-generation PVD coatings are among those currently being investigated.

The Up-And-Comer: Tooth Geometry

Manufacturers have been making improvements in tooth geometry at a slow and steady pace for years. The pace quickened in the mid 1990s, when progressive design technologies such as 3D machining simulation software arrived on the scene, making it possible to minimize field testing, which was typically long and costly. Using these new tools, innovations such as variable tooth height/set forms were optimized, helping shops get the most from their band-sawing investments.

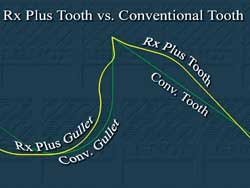

New developments, such as the recent introduction of a band saw blade with a tooth design that provides a larger tooth cross section, indicate that there is more room yet for manufacturers to make big breakthroughs in tooth geometry. This particular tooth design’s increased cross section provides a reinforced cutting surface, which eliminates tooth strippage, prevents premature failure, reduces burring, removes chips more quickly for long life and provides low vibration and noise levels.

We can expect other manufacturers to follow suit with similar improvements in tooth design as we become increasingly aware of the ways in which even the minutest, but specific, changes in tooth geometry can affect cutting performance.

Chuck Wahr is the director of marketing, band saw blades and sawing fluids, for Lenox, a manufacturer of band saw blades, hand tools and power tool accessories.