Captive Shop Must Still Compete

Often, a captive shop seems to have it made by job shop standards. In the case of this division of ITW Welding, “work is not given, it’s earned.”

In 1929, a young Niels Miller was tinkering around with the idea of making a small, portable electric welder in his garage. Little did he know at that time that his pioneering effort would help create an entirely new way of looking at personal and professional welding.

Until that time, arc welders were large industrial three-phase welders that resided in factories. The small businessman and farmer had little or no access to these machines, so repairs could be difficult to achieve. Recognizing a need, and wanting to be the one to fill it, Mr. Miller went about building his first welder. It was an interesting contraption contained within a wooden box, but it worked. He continued working to improve his product. After three more versions of built-in wooden boxes, he developed one contained in a steel box, and soon after Niels loaded up his truck and hit the road. He went from farm to farm selling his portable welders; thus the Miller Electric Manufacturing Co. was born.

Featured Content

Miller Electric remained a family owned and run business from 1929 until it was sold to ITW in 1994. ITW was formed in 1912 after Chicago financier Byron Smith teamed with a group of inventors that had an idea to improve gear grinding, and Illinois Tool Works was born. Today, ITW is a Fortune 200 company based in Glenview, Illinois, that employs more than 50,000 people worldwide.

Nestled into a neighborhood of single family homes and small businesses, Miller Electric’s headquarters is located in Appleton, Wisconsin, in a nine-building campus with four more buildings on the outskirts of the city. Miller Electric moved into the first building of this complex in 1942. Today, ITW Welding’s Appleton locations have approximately 1,300 employees and a total of about 3,000 workers. ITW Welding annual sales is $1.7 billion.

Standing Out to the Inside

Adam Utecht, engineering director of the Components Division, says, “We are an internal fab shop to ITW Welding, and we are a profit center. One of the things that’s unique is even though we build components for other ITW Welding divisions, they don’t have to buy from us,” he says. Mr. Utecht has been with the welding division for 10 years, starting as a mechanical engineer intern and working his way up from there. “There are certain markets we want to play in. We have narrowed these markets down to our four core competencies,” Mr. Utecht says. About 60 percent of what goes into welding equipment comes from ITW’s internal position, with the remaining 40 percent coming from the outside.

The Components Division has about 370 to 400 employees, depending on seasonality, but has only five supervisors for this entire area. How does the division do this? By using a enlightened employee empowerment program: each of the 15-20 manufacturing cells in the division work as an autonomous team, managing themselves as their own small companies. Each team elects its own representative, not to serve as a boss, but only to discuss any issues with the supervisors and engineering management.

Each cell will get an order, review it, schedule its own production, correspond with engineering managers, order the necessary materials to complete the job and deliver it on schedule. This is a true just-in-time (JIT) production mind-set facility. Each cell even has its own mission statement to guide them.

Each day, the cells prepare a status report on their current jobs. Only those that show a late status are on the report that is sent to the supervisors. Only then will the supervisors dig in to help with whatever the cell needs to get the job back on track. “No problem, no involvement. We really rely on our team leads and our shopfloor employees to manage their own work area,” Mr. Utecht says. “They manage their own small businesses, every cell gets its own profit and loss statement each week.” They know exactly how profitable they are, they know what they have spent on labor, materials and on small tools. “Everything we do is in cells,” says Doug Weisshahn, project technician and NC programmer. Mr. Weisshahn started as a machinist 28 years ago with Miller Electric, and in 2005, he moved into a CNC programmer role. About three years ago, Mr. Weisshahn took on the position of process technician, which is like a manufacturing engineer. “Their labor is tied down to a production area, their investments and deprecation is tied to that area so they can calculate a labor rate. The sales from that area are tied back to them,” he says.

Mr. Utecht says he does a lot more coaching than he does directing. The supervisors will not micromanage and make every little decision. In addition, workers at all levels contribute to the continuous improvement atmosphere. Shopfloor workers even weigh in on how they want new equipment positioned on the floor. “Who best understands the intricacies of how that machine will be used and how its position will help or upset the workflow of that area?” Mr. Weisshahn says.

All of the cells have an average of between 250 to 300 components, assembly or part numbers they support. “For example, we will have a production cell with about 18 employees; they run higher volume Swiss components. They won’t bid anything unless it’s more than $10,000 in revenue,” Mr. Utecht says. “They all have their focus and niche, so we gear that equipment and their processes around that.”

High Demand Part Production Need

Copper MIG welding nozzles is one particular component type that drives high demand for the Miller team. Besides the high volume needed, various configurations are also required. These nozzles are consumables that also push production numbers higher. Due to the overwhelming demand, the Components Division challenged its vendors to find solutions to its copper nozzle production needs. Hydromat Inc. in St. Louis, Missouri, was one of the companies asked to submit a solution.

Hydromat was already a known entity to the Components Division; it had been running old legacy-style Hydromat rotary transfer machines since 2001 making welding tips. Recently, the division created a new area to manufacture tips—moving one of the rotary transfer machines from another part of the complex and moving four other machines from the Beecher, Illinois, location. Two of those being double production machines with dual bar feeder setups.

As the company relocates departments for better efficiency, it also created a new area specifically for the manufacture of nozzles, in which now resides a new Hydromat Epic R/T 45-12 machine, its first full CNC-type Hydromat. Previous production of most of these nozzles were done in-house on traditional CNC lathes with secondary operations and the rest were outsourced to third-party suppliers. A review was in order. “We did a full option evaluation. We actually went down four different avenues and broke into teams exploring the different production processes,” Mr. Utecht says. “Then we would meet back and review where we were, and what made the most sense.”

Mr. Weisshahn explains how the company looked at the status quo, leaving the process as it was. The team reviewed it, drawing the part through a transfer press and looked at high volume multi-spindles. As another option, the team looked at machining the part out of solid barstock. The team at Hydromat came up with a process that would machine the part without secondary operations and minimal scrap, not to mention bringing the work back in house.

Developing a Process

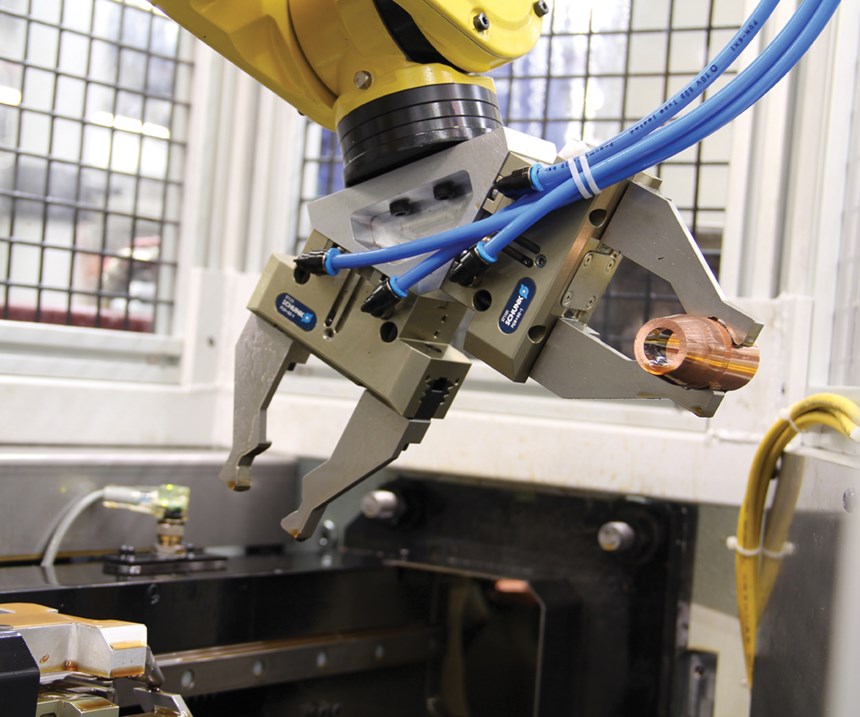

Hydromat proposed that during the machining process, the part would be removed from its CNC Epic, which would be robotically integrated to be swaged in a hydraulic press and then reloaded back into the rotary transfer process to be finished. Hydromat engineers incorporated a pneumatic unloader/loader, a FANUC robot, and a turntable on the Neff hydraulic press to accomplish this process.

Besides increasing production, elimination of scrap was a necessity, and the only way to eliminate excessive amounts was to use tubing and apply a forming application of some kind. Miller Electric needed the versatility of machining, but the efficiency of stamping; blending these two processes together created a workable hybrid.

The Hydromat project was a collaborative effort, and Mr. Weisshahn played an integral part in the improvements. With this particular project, 80 percent of communication with Hydromat’s staff was handled by Mr. Weisshahn. “This is our first machine that has full integration with automation going inside and outside of the machine. Having examples of this was helpful,” Mr. Weisshahn says. “Part of choosing Hydromat was familiarity, knowing that we have the five machines already.”

The Components Division’s new Hydromat uses the company’s full CNC system called Embedded Motion Control (EMC). It features plug and play programming capabilities that are integrated into each tool spindle unit, increasing flexibility and cutting setup time. The versatility of the machine tool and its full CNC gives Miller Electric the capability to eventually run 34 different part programs on different diameter tubes for high efficiency JIT production. “It will be all the same type of material, C122 copper, but different sizes of material,” Mr. Weisshahn says.

Of the 34 there are a few part numbers that will get turned complete in the Hydromat and won’t get swaged. The use of copper for the nozzles has to do with the thermal properties of the welding process. Copper is a similar metal and doesn’t want to bond with mild steel while welding. Tellurium copper could be used, but the company uses C122 because of the forming properties. But the material proves to be difficult to machine. “It is almost impossible to break a chip on this type of copper. It’s very abrasive and hard on the tooling,” Mr. Weisshahn says.

Progressive Machining

The Hydromat machine spreads the sequence of cutting operations over a number of stations, which reduces the overall cycle time for each part to a fraction of that of a single spindle lathe. In this case, the EPIC R/T 45-12 has 12 stations for machining, loading, unloading and a number of other processes.

During the Hydromat sequence of operations, the workpiece is fed into the collet and the saw cuts it to the proper length. The table cycles the part to each station for the individual processes. The table locks in place with a precision ground Hirth ring, providing the station-to-station repeatability and accuracy.

As the part moves from station-to-station during the process, it receives a number of cutting operations, and also a knurl and a roll stamp with the product name and part number. At one point during the sequence of operations, the part goes through an extraction process and to the Hydraulic press table. The table cycles in sequence with the table in the Hydromat. The robot places the part on a turntable where it is processed through the hydraulic press.

After the part is swaged by the hydraulic press and is rotated into position, the part is replaced in an inverted position in the Hydromat collet via the return process of the robot and pneumatic loader. When finished, the new nozzle is unloaded and placed on a conveyor belt. Rather than the minutes needed to produce each nozzle on a single-spindle lathe with secondary operations, now the cycle time for each part is a mere 8 seconds.

Mr. Miller expects this new system to produce several million welding nozzles per year. This new system represents a quantum leap in producing welding nozzles for ITW Welding as it uses the company’s own version of lean manufacturing and JIT production to weld together productivity and profit. Even in a captive shop, securing a steady flow of work is a good thing.

RELATED CONTENT

-

The Effects of Automation on Manufacturing

Companies that are not currently using automation in their manufacturing processes should be considering it.

-

Making Waves with Lathe Automation

After years of relying on an extensive machining cell for part production, this marine equipment manufacturer has now reduced part handling and improved quality through use of single-setup lathes and automated loading and unloading.

-

Choosing an Automatic Bar Feeder

The bar feeder is the most common form of automation for turning operations. Selecting the right one requires consideration of the applications for which it will be used.