Ceramic Fibers For Precision Deburring

Removing burrs from precision machined parts is the bane of every metalworking shop. These pesky residuals add to the cost and complexity to most production processes. Moreover, most customers for precision parts mandate a zero-tolerance policy for burrs.

Removing burrs from precision machined parts is the bane of every metalworking shop. These pesky residuals add to the cost and complexity to most production processes. Moreover, most customers for precision parts mandate a zero-tolerance policy for burrs.

Featured Content

As cost cutting drives more applications away from labor-intensive secondary and tertiary operations, better tools are needed to help consolidate processing into a minimum amount of handling. In other words, if deburring can be done in the machine, it’s better than on a bench. What is needed are tools that can consistently remove machine-produced burrs both visible and hidden on complex parts.

There are many approaches for shops looking to take the labor out of deburring. Processes such as vibratory deburring, Emory clothes and stones, impregnated nylon brushes, wire and brass brushes and shot blasting are among options available for shops.

Another deburring tool option is available from a Japanese manufacturer named Xebec. Production Machining came across this company while visiting the JIMTOF show in Tokyo and found its alumina fiber deburring tool of interest.

The core technology that Xebec brings is a process the company developed to draw alumina fiber filament into a brush bristle shape. Stones made from abrasive alumina are not new, but creating filaments from this material is a relatively recent development.

Like a grinding wheel, the tip of these fibers do the cutting when applied to the burr through rotation and feed. Also, like a grinding wheel, which exposes new cutting edges as it wears, these rods are also self-sharpening. The cutting action of the fine alumina fiber rod tips provides continuous cutting edges for precision burr removal of fine burrs as much as 0.1 mm in base thickness.

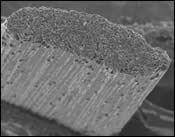

As shown in the micrograph, each fiber is composed of 1,000 fine alumina filaments bound together using a resin binder into each single rod. Each filament is a cutting edge providing 1,000 cutters per rod. These columnar filaments make up a single fiber rod, which in turn, is bundled into a brush shape. Unlike abrasive impregnated substrates, these rods contain 75-percent alumina compared with 30-percent for impregnated nylon brushes.

For many deburring operations, tool “adaptation” is a key processing capability. An abrasive brush configuration works well for these applications because it is flexible enough to conform to tight geometries and remove the burr without disturbing the parent metal.

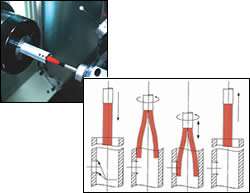

The company produces its cutting fibers in a variety of configurations to handle various deburring chores. The ends of the brush can be applied to OD and facing work that needs deburring. These operate like a face mill on flats and chamfer edges. An adjustable sleeve determines the amount of brush protrusion and thus the stiffness of the brush face on the surface being deburred.

Cross-hole burrs are particularly nettlesome for shops. Xebec has a line of tools that uses centrifugal force to grind away these difficult-to-reach burrs. In operation, the tool is fed into the bore to be deburred with the spindle off. Inside the bore, the spindle is activated, and rotating abrasive brushes flare from centrifugal force. As the tool is fed back and forth inside the bore, it generates a grinding action that abrades the internal burrs without breaking the edge pattern of the cross-hole. Grinding speed and pressure are a function of the spindle speed and stroke.

The company makes these tools for use in bores from 3 mm to 20 mm in diameter. The tools are designed for use in machine tools including live tool turning centers, machining centers and robots. Deburring can be performed wet or dry and in materials including stainless, chromium-alloy steel, steel, copper, aluminum, magnesium, Inconel and titanium.

Precise mechanical parts for aerospace, automotive, medical and electronics industries cannot tolerate even the finest burrs remaining after machining. Xebec designed its cutting fiber deburring tools to help assure parts producers that the no-burr spec is being met.