Choosing the Right Aqueous Cleaning Operation

For most machining processes, water-based solutions can be applied using tailored technologies for specific applications.

When determining the best way to machine a part, dozens of variables must be taken into consideration when choosing the most effective method of cleaning the finished product using an aqueous system. In addition to the customer’s own requirements, manufacturers must also factor in part geometry, the material used, the shape of the chips that will be generated, throughput, and the need for quick change-outs between different types of parts. The temperature of the solution—and of the part itself as it exits machining—is sometimes an issue as well, as is the process being performed. Standard cut parts can often simply be sprayed off, while lapped surfaces require ultrasonic cleaning to remove tiny particulates.

Because so many questions need to be answered by the shop about their customer’s cleaning requirements, it’s no surprise that the Cleaning Technologies Group, LLC, Ransohoff says 80 percent of the systems it sells are custom designed, according to Jeff Mills, national sales manager for the Ransohoff division of CTG.

Featured Content

“Our first questions will generally be ‘what are you making, what are the materials you are using, what is your production time allowance, and what are your customers’ requirements?’,” he says. “From there, we can begin making suggestions about the type of cleaning process that might work best for them and even how robotics might be incorporated. And we don’t take a stock machine and start adding options. The vast majority of the time, we’re designing and building these systems from the ground up according to the customer’s exact specifications. Then, we have the blueprints on file should they need another system or another dozen of them.”

According to Mr. Mills, there are four basic methods to performing water-based cleaning operations in metalworking: standard spray, total immersion, ultrasonics, and high-pressure spray.

Of these, the first and last are referred to as “line of sight” processes, in which anything on a part in sight is cleaned, even at the bottom of relatively shallow cuts and holes.

The two remaining processes call for parts to be immersed in the cleaning solution, and even spun and agitated, in some cases. These work best for more complex parts with deep recesses in which chips and other debris can be hidden.

This article covers how each process is performed, to what parts they are most suited, and the kind of work a machine shop is doing that would lead them to choose one process over another, and even to commission a custom system combining parts cleaning methods.

Standard spray provides great flexibility among parts of different shapes, materials and sizes. Such systems are typically batch loaded for use in general industry, such as companies machining parts for appliances or garden equipment.

Parts are positioned on a rotary table or within a specialized fixture, depending on their geometry, and they are sprayed with water mixed with different concentrations of surfactant, which disperses oil and debris from the surface of the part. Any remaining liquid is blown off using compressed air. More acidic cleaners are used with soft metals such as copper, brass and bronze, while steel products require that attention be paid to the pH level. A solution with a pH of less than seven is considered acidic, while a solution with a pH higher than seven is referred to as basic, or alkaline. A standard spray system can be modified—automated loading/unloading, the incorporation of additional cleaning systems for special applications—and is a simple, straightforward, cost-effective process for a variety of manufacturers.

Total immersion is generally considered first when features or deep recesses on the part prevent direct line of sight inspection. Cutting fluids, chips and other particulate matter can evade even high-pressure spraying, so some parts must be fully immersed in the cleaning solution.

One approach involves loading parts into a basket, which is then introduced into the self-contained cleaning chamber. The parts are first sprayed while the basket rotates in a circle, and then the chamber is filled with an aqueous solution with whatever chemistry is required by the process. The basket is then agitated, plunged into, and then withdrawn from the bath, which serves to channel the solution deep into the recesses, thereby removing any remaining excess chips or fluids. This method basically picks up where a standard spray system leaves off, adding total immersion to the process, and then blowing the parts dry. Automation is also an option, as is the case with all four of the standard categories of aqueous cleaning.

Ultrasonics can be layered on top of the standard spray and total immersion processes, adding the powerful element of cavitation to the cleaning system. Once spraying has been completed to remove gross contaminants, the chamber is filled and high-intensity sound waves are introduced into the solution, forming vacuums within the crevasses of the parts being cleaned. Depending on the frequency of the sound waves, contaminants are removed at the lower end of the scale while material can actually be removed from the part surface at higher exposures. Basically, the vacuums collapse or implode, bringing the solution into contact with the surface in a burst of energy that carries contaminants away. Mr. Mills says the company has managed to meet cleanliness specifications down to 50 microns.

The types of parts for which this process is well-suited include transmission shafts, turbine blades and medical implants. Ultrasonic cleaning is ideal for precision machining applications with stringent cleaning requirements. Aerospace, electronics, automotive and medical markets have the strictest requirements.

High-pressure spray, “a line of sight” process, is primarily used in deburring applications. Whereas sanding or grinding can take away too much material from the part’s surface, a high-pressure spray can remove burrs without damaging the underlying substrate. With an upper range of 10,000 psi, the Ransohoff line of high-pressure washers generally operate in the 3,500-psi range for materials such as aluminum and approximately 5,000 psi for parts made of steel.

Aqueous systems can be designed to fit almost any part cleaning application and are safer than using solvents, which contain highly regulated chemicals such as alcohol and trichloroethylene and must be operated under a vacuum so no fumes are released into the working environment. In fact, most of the aqueous solutions we supply are safe enough to go right into the sewer system,” Mr. Mills says. “It’s contaminants introduced by the machining process such as oil, greases and lapping compounds that have to be filtered or disposed of properly.”

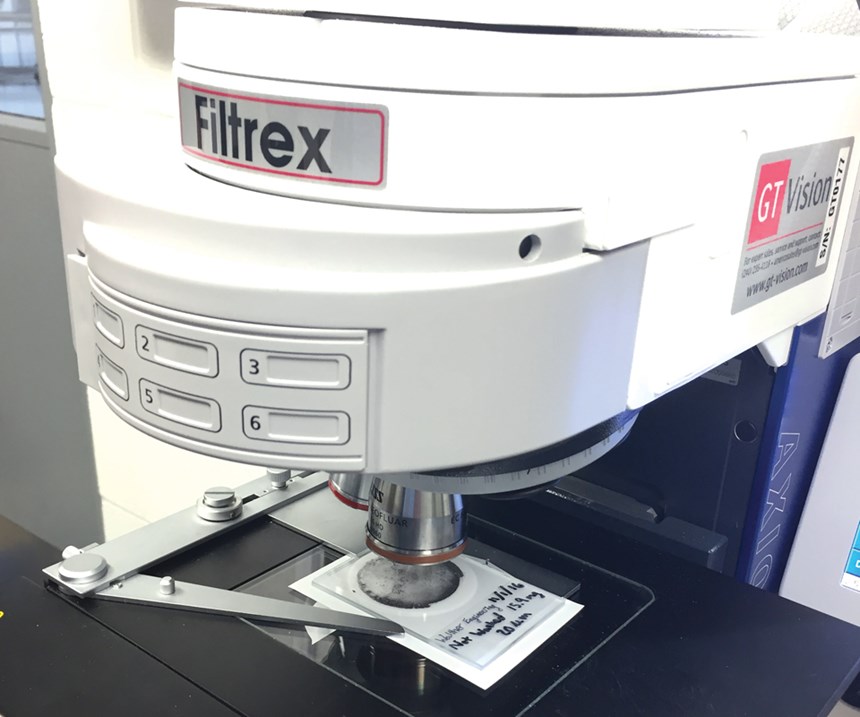

Whatever system is chosen, CTG offers laboratory testing to ensure that the final customer specifications for cleanliness are met. In fact, the company’s tech center houses a cleanroom rated at class 10,000 using gravimetric Millipore filters to conduct microscopic particle size analysis.

“If a company will provide its required production rate and cleaning specifications,” Mr. Mills says, “we’ll run a lab test before delivery as proof that the machine will perform as promised.”

When it comes to maintaining existing cleaning equipment, CTG offers a two-day preventive maintenance service in which a technician visits the facility and runs tests to determine how efficiently the system is operating. Again, many factors come into play, beginning with the type of machining process being performed, as well as how efficiently it is running. As the word “system” implies, increasing connectivity between once-separate systems mean how one is operating can affect the other. If there are too many particulates found in the spent solvent, a pre-spray could be added so that the parts aren’t carrying unnecessarily high amounts of debris into the cleaning system, clogging its filters. If an obstruction causes problems with the flow of the solution through the system, the machines are programmed to alarm out and shut down. They are also capable of running in “gray mode” when no parts are being loaded, essentially powering down to avoid excess energy costs.

Just as robots have revolutionized many areas of manufacturing, recent years have seen automation introduced into parts cleaning systems in ways that have increased flexibility and productivity. Mr. Mills is quick to add, however, that there is a significant difference between aftermarket or “peripheral” systems that can be added to a machining cell after the point of purchase and the newer integrated systems that are wired into the cleaning system and monitored through its Programmable Logic Controller (PLC). The PLC allows for seamless interaction between the robot and the cleaning machine while loading and unloading parts. In addition, the results can be fed into the company’s facilities information system for both documentation and process review.

Providing a streamlined footprint, a more efficient use of space on the shop floor, and the ability to conduct lights-out machining, are other benefits to robotic loading and unloading.

Mr. Mills says he has seen increased interest in efficient cleaning systems over the span of about five years and more automation being incorporated into machining/cleaning cells in the past three years. “Ninety percent of our customers who request a quote have a cleaning specification they have to maintain, whether that be visual inspection, a white glove test or a complete lab test that determines the size and weight of particles left suspended in the solution,” he says. “Parts cleaning is becoming more of a priority than ever before.”

Published in the June 2017 issue.