Efficient Operation With High-Pressure Coolant

Manufacturers spend millions of dollars on liquid coolants each year to help machine tools cut metal more efficiently. In many cases, however, the effect of this coolant could be greatly enhanced—in some applications by 100 percent or more—by using a high-pressure coolant delivery system.

#metalworkingfluids

Manufacturers spend millions of dollars on liquid coolants each year to help machine tools cut metal more efficiently. In many cases, however, the effect of this coolant could be greatly enhanced—in some applications by 100 percent or more—by using a high-pressure coolant delivery system.

A High-Pressure Job

Coolants are used to reduce the amount of heat and friction at the point where a tool cuts into a metal workpiece. This heat reduction allows the cutting tool to operate at higher speeds and reduces tool wear. However, at the lower pressures typically used to deliver cutting fluid, the coolant cannot effectively remove the majority of heat at the cutting point. Instead, the coolant washes over the tool, toolholder and workpiece, cooling the surfaces somewhat, but not removing the intense heat within the cutting area itself. In fact, most of this heat is conducted to the material around the shear zone and to the tooling, thus keeping the temperature at the cutting point higher than desired.

Featured Content

By directing the coolant stream more precisely and with the optimum amount of pressure, dramatically more heat can be removed from the cut zone. This degree of cooling also enables the cutting tool to remove greater amounts of metal, thus improving machine tool cycle times.

Additionally, the high-pressure coolant stream helps break up chips and remove them from the cutting area more efficiently, which means the cutting tool spends less time re-cutting metal chips. The combination of reduced heat and more efficient evacuation of chips prolongs tool life and makes replacement more predictable because the cutting tool wears out naturally, rather than failing prematurely because of excessive heat or chip damage.

New Technology

The latest machine tools deliver increased spindle speeds while maintaining tolerances better than ever before. However these higher speed and feed rates place greater demands on the cutting tools as they encounter more intense heat, greater stress and increased chip accumulation in the cut zone. As a result, if the cut area is not properly cooled and the chips efficiently evacuated, the cutting tool will require more frequent replacement, which reduces overall throughput. Properly applied high-pressure coolant allows users to achieve maximum performance from these faster machine tools.

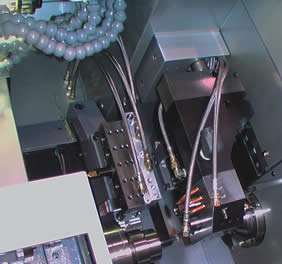

In the same way, high-pressure systems can help owners of the increasingly popular multifunction machines get the most out of their investment. Because these machining centers perform a variety of operations, they often need multiple high-pressure coolant delivery ports to suit their various applications.

Other Benefits

High-pressure coolant delivery can assist in a variety of components of the machining operation. Micro-drills, for instance, are prone to unexpectedly snap because of their diminutive size and tendency to wobble in operation. Replacing the drill, of course, creates costly downtime. Applying high-pressure coolant streams to these applications actually makes the drills more rigid, thus reducing breakage. High-pressure coolant can also help to improve part finishes. Thanks to more efficient chip removal and reduced heat, the workpiece surface is less likely to be marred by chips or distorted by excess heat. Thus, more efficient machining operations, including better capabilities for combining operations on a single machine, can be obtained through improved chip evacuation from fixtures and the machining area.

Maximizing Results

Adding a high-pressure system to virtually any cutting station will yield some improvement in tool wear and machine efficiencies. However, getting the greatest benefit from the equipment requires a thorough understanding of the cutting application so that the system can be properly installed.

According to Kenzie Roaden, a high-pressure systems application specialist for LNS America (Cincinnati, Ohio), “There is a very narrow window of about 10 to 20 thousandths within the cutting area that must be precisely hit with the high-pressure stream for optimum results. I’ve observed systems that were not well installed but still delivered 40-percent better tool wear. The customer was pleased, but what he didn’t know was that, if properly installed for that specific application, the tool life could be extended 140 percent.”

Thoroughly understanding the application is critical to properly specifying and installing a high-pressure unit. It is important to use the optimum amount of pressure and flow, recognize the type of nozzle or orifice to place at the end of the tubing that will properly direct the coolant stream, and set the correct angle and distance from the workpiece to properly hit the “sweet spot” of the cutting area.

"We’ve seen high-pressure installations in which the tubing was simply put in place with no more than a crimp in the end to direct the coolant flow,” says LNS coolant systems R&D Manager Scott Hrvatin. “That’s like running your high-pressure coolant through a fire hose and hoping you hit something. It’s very important to use an orifice at the end of the tubing that precisely matches the application.”

RELATED CONTENT

-

Maximize Coolant Life with Efficient Tramp Oil Removal

Increased demands for high surface finish and close part tolerance create a greater need for manufacturers to purify coolants that are constantly being cycled through precision machinery.

-

Optimize Minimum Quantity Lubrication Control Through a CNC Program

Minimum quantity lubrication (MQL) on a lathe offers many benefits when implemented properly. MQL becomes more of an asset when lubricant and air delivery can be controlled from a CNC program.

-

Considerations for Machining Exotics

In manufacturing, the term “exotic” is used to describe materials that display excellent wear characteristics, durability and service life in high heat, extreme cold or corrosive environments.