Five Options for Higher Productivity

Today’s market is more competitive and time-driven than ever, and seemingly small workflow improvements can often result in huge gains in the medium and long term. Accuracy and throughput can be greatly increased simply by choosing the best tool for the job.

#workforcedevelopment

Today’s market is more competitive and time-driven than ever, and seemingly small workflow improvements can often result in huge gains in the medium and long term. These cumulative advantages may mean the competitive difference between keeping and losing crucial clients and contracts.

Accuracy and throughput can be greatly increased simply by choosing the best tool for the job. Enhancements can come in many shapes and sizes, but here is a list of five improvements that could prove quite significant for shops with one to 40 machinists.

Featured Content

Add a digital readout to any mill, lathe or grinder currently without one. The digital readout (DRO) is a must for shops everywhere. Fitted to machines such as lathes, cylindrical grinders, milling machines, surface grinders and boring mills, DROs allow an operator to boost both speed and accuracy. They are highly functional, providing instant fingertip control over the most frequent shop operations. Here are some specific examples of common DRO functions that can quickly add to a shop’s productivity: a 1/2 function to divide the current axis value in half, allowing quick and accurate location of the center of a workpiece; the ability to compute a cut across an incline; a full scientific

calculator; absolute and incremental modes, allowing the operator to set the unit’s coordinates to the part’s absolute zero point or to some other relative value; and the ability to store huge numbers of points in the DRO’s built-in memory.

Add a power drawbar to any manual milling machine without it. Manual drawbars are very difficult to change and can pose additional risk with frequent trips up the shop ladder. Power drawbars are used in place of manual drawbars, and they have advantages, including substantially faster toolchange times, increased productivity on milling machines and decreased downtime on CNC mills, and more productive cutting time, reducing operator fatigue.

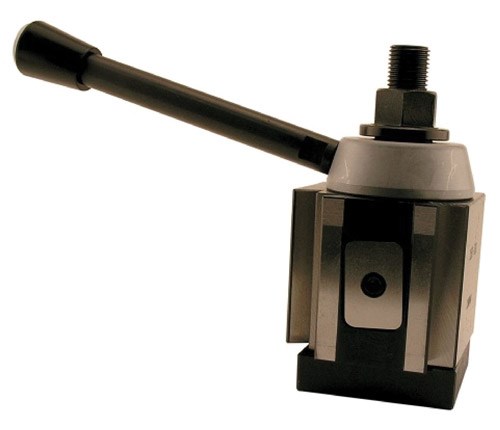

Install a quick-change toolpost system on lathes. Regardless of a shop’s size, ideas for speeding up simple jobs on a lathe are always welcomed. The quick-change toolpost is a great way to do just that. With this system, the needed tools are always set in the holder, and if any adjustment or change is required, it can be done quickly with little hassle. Such shortcuts may seem minor on their own, but added up over the course of a year’s work, they contribute greatly to overall productivity.

Use an automatic cycle bandsaw to cut stock. Yes, it’s big, and no, it’s not cheap, but the automatic cycle bandsaw can streamline cutting activities in a facility and, therefore, pay for itself in short order. These machines are fully automatic, meaning all that needs to be done is to preset the number of cuts, adjust the stock feed for the desired length of the cut and let the saw do the rest. It will repeat the automatic cycle and switch to off when finished or when the stock is exhausted. With no attendant required, the time savings are enormous.

Replace manual tool room machines with CNC to save setup and run time. It used to be that even the mention of CNC caused the company accountants to sweat. Times have changed, and where once CNC was cost prohibitive to all but the largest facilities, advances in technology have brought it within the reach of just about every shop, regardless of size. In the old days, a trained engineer was required to run center lathes, vertical mills, routers and various other important pieces of machinery that are all now candidates for this technology.

CNCs remove the highly trained technician from the equation and can be run safely and effectively by operators with far less training, providing significant cost savings. Hundreds or even thousands of the same design will be rendered identically, removing the variance inherent in human-guided processes of old. Modern production demands that products be manufactured to the most precise specifications every time, and CNC can accomplish this.

CNC machines can be used continuously all day, every day and only need to be switched off for occasional maintenance and can be easily and inexpensively updated by improving the software used to drive the mechanics. The technology also allows accurate calculation of turnings for resale purposes, while simultaneously decreasing scrap.

RELATED CONTENT

-

The Many Sides of Workholding

Here's a broad look at different ways to approach workholding, from bar feeders to collet chucks to robotics.

-

Job Shop Automation: Fast, Simple and Agile

When done right, automation can provide important benefits. Here’s a look at automation options to suit the varying needs of typical job shops.

-

10 Smart Steps to Take Toward Recovery

With many manufacturers facing challenges in light of the novel coronavirus pandemic, these 10 steps can help position manufacturers to find success.