From Virtual To Reality

This article tells how a shop used infomation available on the Web to solve a tough production problem on its shop floor.

Next time you spot an employee “surfing the Net” on company time, don’t be too quick to shut them down. Instead, think about Busche-CNC (Albion, Indiana), which has surfing to thank for eliminating a costly bottleneck in a high-volume, rough turning operation on difficult-to-machine material. Clearing the bottleneck improved the shop’s quick delivery capabilities to its Tier One automotive customers and helped the company contain costs in this highly competitive business.

Jerry Busche’s surfing uncovered a new tool that turned around a real bottleneck operation on a “bear of a metal.” Mr. Busche is vice president for the diversified contract machining company, which operates seven plants located in Albion. By coincidence, just days before Mr. Busche went Web surfing, Ingersoll Cutting Tools had posted the recently released Hex-Turn tool on its Web site.

Featured Content

New Job, New Challenge

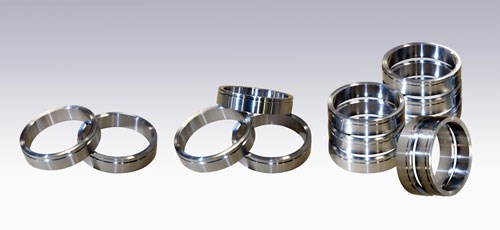

Actually the story began far earlier, when Mr. Busche was still working out the wrinkles on a new job—a family of automotive ring gears with an aggregate annual volume of 2.75 million pieces. Materials were steel forgings, mainly 5130 and some hardened 4140. The bottleneck was the rough turning and facing operation, which ran too slowly and demolished the tooling.

The 400-person shop machines the ring gears in seven, two-lathe machining cells that run 24/5. The original inserts for the application were rhombic, with opposing 80-degree and 100-degree edges on each side. Plans were to rough the part ODs with the 80-degree edges, then do the faces with the 100-degree edges and use all eight edges per insert.

Gummy Feedstock, Severe Cratering

As it turned out, the 5130 steel was so gummy that the inserts cratered after less than 20 cuts. Because of the increased cutting pressure, toolbars snapped every other day on average.

Type 5130 steel is known to be a bear on rough turning tools for several reasons. The material is so gummy that it generates severe cutting friction, built-up edge and heat. Moreover, in continuous cuts, the hot chips come off stringy and tend to hang up on the insert, worsening the heat problem.

As an interim measure to minimize downtime until a permanent solution could be found, Busche’s manufacturing engineer, Mike Pearson, incorporated four backup toolbars into each tool package and programmed the machine to automatically index every 17 cuts. That way, the operators had to shut down only once every 68 cuts to index all four toolbars, instead of every 17 cuts. Because the cratering often wrecked the insert’s opposite face, however, the operation rarely produced more than two usable edges from any insert.

Cratering also quashed the original plan to rough both the OD and face with different edges of the same insert. Experience indicated they would need separate tools for each operation.

“We were looking at buying an awful lot of toolbars and inserts to keep the operations going this way,” Mr. Busche explains.

Looking…In All The Right Places

So, he turned to the Internet to find a better match. This was about the time Raymon Avery, Ingersoll turning product manager, had introduced the company’s new hexagonal turning inserts and holder on the company’s Web site. Sure enough, Mr. Busche spotted it.

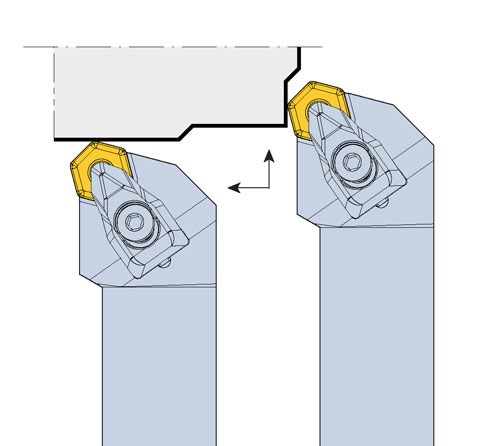

Ingersoll had developed the tool specifically for turning and facing in tough applications where strength was important to success. The insert’s hexagonal shape comes closer to a true round—considered the strongest possible insert shape—than the previous rhombic inserts. And being double-sided, the insert offered 12 edges, all equally able to turn and face.

Potential Win-Win

Mr. Busche talked it over with Mr. Avery, and the two agreed they had a likely fit with real upside potential. Busche stood to eliminate a problem that had eaten up its tooling on a very big job, while Ingersoll would get real-world validation for its newcomer in a formidable application.

First Blush

For the trial, Mr. Pearson and Ingersoll field rep Tony Lovatto chose one of the cells running a 6-inch-diameter ring gear blank. This is the highest-volume size in the part family.

Actually, Busche makes two ring gears out of each forged blank. After completing all machining on the ODs, IDs and faces, they split the blank in two with a cutoff operation.

Mr. Pearson and Mr. Lovatto, together with Ingersoll engineer Mitch Bair and Busche’s Levi Krider, began the test early one morning a couple of weeks after Mr. Busche’s Web surfing foray. Mr. Krider and Mr. Lovatto installed the tooling while Mr. Pearson and Mr. Bair revised the CNC program to accommodate the change in insert geometry. To be conservative, they set up the test to use separate Hex-Turn tools for the OD turning and the facing, just like before.

About 1 hour later, they started running parts at the same machine settings as before. The new tool outlasted the old one by more than 8 to 1—140 cuts versus 17 cuts. Moreover, edges wore out gradually rather than breaking off catastrophically.

Once the dramatic gain in edge life—Busche’s number one priority—was established, the feed rate was gradually ramped up, from 0.017 ipr to more than 0.020 ipr. The edge life remained at 140 cuts or more. Next, Mr. Pearson again altered the program to enable a single Hex-Turn insert to handle both the OD and the face cuts, as originally planned. When that proved successful, they again raised the feed rate to 0.025 ipr, a 50-percent jump. Still, the edges lasted through 140 cuts.

“It was essentially a drop-in replacement,” says Mr. Pearson. “The only reprogramming was to accommodate the new insert geometry, to realize the original plan for a single insert to handle both cuts and to eliminate those redundant tools. That’s the kind of reprogramming I’d gladly do any day.”

Up And Running

Today, with all seven machining cells up and running with the new Hex-Turn tools, Busche has seen the bottleneck simply disappear, with resulting improvements in delivery and cost containment. Standard practice on the 5130 forgings is to turn the ODs to 900 sfm, with a 0.150-inch depth of cut at 0.0250 ipr.

For the runs in hardened 4140 steel, Busche simply eases back slightly on the feed. Still, the hardened parts run about 40 percent faster than before, with the same improvement in edge life.

Shape Matters

What accounts for the performance gain? “Other things being equal, the hexagonal geometry is intrinsically stronger than the previous rhombus,” explains Ingersoll’s Mr. Lovatto. “There’s also a pressed-in positive rake and chipbreakers on the top face, leading respectively to freer cutting, cooler running and better chip control. Improved coatings also reduce friction at the cutting face and resist built up edge, which can be a nuisance when machining gummy materials. In addition, the wiper geometry on the cutting edge allowed us to get very aggressive on the feed rate.”

Like Walt Disney’s fame, Mr. Busche’s solution to his production problem “all started with a mouse.”

RELATED CONTENT

-

When Thread Milling Makes Sense

Threading a workpiece is a fundamental metalworking process that every manufacturing engineer takes for granted.

-

Plateau Honing Improves Finish and Lubrication Control

Plateau honing is a process that improves cylinder wall surface finish by removing tiny peaks of torn or folded material and increasing bearing area.

-

A New Approach to CNC Turning

This turning process takes advantage of a turn-mill’s B-axis spindle to vary a tool’s approach angle to optimize chip control and feed rates.