Hard Turning’s Strong Finish

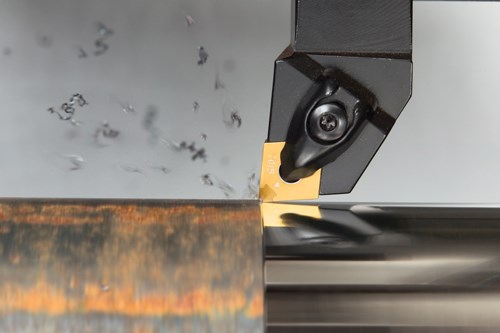

With the right methodology in place, this alternative to grinding can often save money while adequately meeting surface finish requirements.

Grinding operations are known for the superior surface finishes they can achieve. But the cost of a grinding machine, its relatively narrow scope of application, and the limited number of operators capable of running it effectively can be compelling factors in a shop’s mission to find a more practical or cost efficient means of attaining the required surface finishes.

Hard turning can often serve as the solution, but the limitations of this process must also be carefully considered. Hard turning pushes towards the upper end of the tolerances that lathes typically deal with, so all process parameters should be well coordinated to provide the best opportunity for success.

Featured Content

A recent interview with Lathe Specialist David Fischer, from Okuma America Corporation, revealed a number of insights about using hard turning to achieve surface finish specifications.

What’s the Difference?

For many applications, grinding is the preferred process strictly because of the finish it provides. These machines handle the tight tolerances of tenths or millionths without a struggle. Extremely stable machines, they’re made for dealing with super tight tolerances.

The difference in finish is often visible in the “phonograph mark” left on a lathe’s single-point turned surface—a microscopic groove created as the part is rotating that provides a path for lubricant to spiral out away from the component. To bring a turned part closer to a ground finish, sometimes wiper-type inserts are used. But these tools can also create issues because the considerably larger contact area creates substantially increased pressure on the tool—generally 20 to 25 percent more.

But the main focus of hard turning is almost always to get away from grinding, to avoid buying a separate machine or the issues related to swarf disposal.

For successful hard turning, the key components for a machine are that it is rigid, thermally stable and very accurate. If a shop already has a machine that can handle the rigors of hard turning, it should be in a good position to get started. But if a shop needs to buy a new machine, is a grinder a better option? The versatility of a lathe should be considered, as not all of the work performed on the machine needs to be hard turning. The choice can be likened to the increasing popularity of multifunction turn/mill machines. The more flexible the machine, the more can be integrated into the process and the more efficient the operation. Beyond their narrow focus, grinders are also typically more expensive than a lathe and require specialized training.

Machine Specifics

Temperature changes in and around a machine can create steady fluctuations in component sizes. Although these variations may seem minute, when tolerances are in tenths and millionths, they can spell the difference between a good part and scrap. One option to compensate for these fluctuations is to add feedback gaging for each part and send the feedback as offsets to maintain the tight tolerance band. Commonly, a running three-part average is kept, offsetting from that while minimizing overcorrection.

But the more thermally stable a machine is, the less impact these temperature changes will have. While Okuma’s turning centers are designed for a range of turning operations, they incorporate features that lend themselves to the high thermal stability necessary for performing hard turning. A number of the machines have been used successfully in this capacity. The machines are designed from the ground up to be thermally stable, with a lot of mechanical design that goes into the machine to make it more stable and predictable. All of the major components of the machine are mounted at the same angle so they will expand and contract at the same angle.

Typical slant bed lathes, designed for more efficient chip removal in high production operations and more ergonomic loading and unloading of parts, also bring with them a more complex shape. This complex shape is more susceptible to torsion and unpredictable contraction or growth as temperatures vary from hour to hour or day to day. This design makes accurate compensation very difficult.

In Okuma’s design, the company looked back at the advantages that the thermally stable flatbed lathes offered and applied these concepts to a two-piece base to eliminate the complex shapes. Mounted on an angled base is the way system—a single casting designed as a cube. This is the key structural component of the machine. While the simple shape is far more predictable for thermal expansion, it still contributes to chip evacuation and ergonomics.

Cutting Tools and Coolant

As important as machine rigidity is to successful hard turning, considerations for cutting tool setups should not be overlooked. Minimizing as much as possible the distance between the turret and the cutting edge will help to keep chatter under control. Of course, this rigid connection is easier to achieve with some workpieces than others.

OD tools are generally relatively stout and the nature of the process allows the toolholder to choke up closely on the tool. But ID gets trickier. While off-the-shelf tooling can often be sufficient for many hard turning applications, custom boring bars may be better suited for ID work, allowing the biggest bar possible to fit into the hole. A jump down to a suitable standard size, perhaps as much as a quarter of an inch, can make a big difference in performance. Tooling suppliers are a great resource for determining the best fit to make sure the toolholder system is as rigid as can be for a given job.

Insert edge preps can also be easily misunderstood when trying to achieve the best surface finish. Most of the time, the edge prep recommended by the supplier is the best bet, and certainly a good starting point. But often one feature of the part will create a problem and require a change. Experimentation is the key here, finding what edge prep works best for each situation. Tooling suppliers do a lot to support customers in this determination.

Generally, the optimum cutting tool materials for hard turning are CBN and PCBN. They perform well in interrupted cuts, offer long tool life, and remain stable amidst the high temperatures of hard turning. Their higher cost is usually easily offset by reductions in processing time and change-over time.

Ceramic cutting tools, while less expensive than CBN and PCBN, can also provide excellent surface finish. Their brittleness, however, can create problems in interrupted cuts.

While many advances have been made in cutting materials, the use of coolant is still recommended where possible for hard turning. But often with interrupted cuts (even very small holes), and depending on the insert grade, the tool may not be able to handle the thermal shock of the coolant.

Mr. Fischer states that sometimes, jobs are set up with interruptions to be cut first without coolant, and then the coolant is turned on to cut the rest of the part. The customer might not understand the reasoning for this strategy and later decide to start using coolant for the entire part, but this quickly breaks down the tool.

Another important distinction is that cutting oils should not be used in hard turning because of the high temperatures involved in the process. Cutting oils can act as an insulator, keeping heat in the cut.

Making the Decision

Hard turning is not a cure-all replacement for grinding. The finish can be a deal breaker, dependent on if the necessary tolerances can be met. Surface finish callout can also create a strong argument for grinding, which provides better consistency. Some applications specify a band of tolerance with a maximum and a minimum, meaning the finish could be either too smooth or too rough. These tolerances can be tricky to hold with hard turning, being highly dependent on the cutting tool being used and the edge prep.

In the right application, though, hard turning is simply the logical choice. While grinding is sometimes necessary to hold certain tolerances and achieve a desired finish, the benefits of hard turning are hard to ignore. Both expense and environmental impact come into play in regards to grinding’s swarf disposal requirements. Availability of skilled operators and the cost of the machine are also legitimate concerns.

Yes, certain parts are more suitable than others for hard turning. It always comes back to the required surface finish and size requirements. Some industries, such as aerospace, even require grinding on certain parts because of the known finish benefits. But if hard turning can be certified into the process, it may be the most cost efficient option for producing the final finish desired.

RELATED CONTENT

-

Keeping Watch on Small Parts

From watch parts to exotic medical applications, this shop takes on the world of micromachining.

-

6 Tips for Training on a Swiss-Type Lathe

There are nuances to training a person to effectively operate a Swiss-type lathe. A shop I visited a while back offers some suggestions.

-

The Evolution of the Y Axis on Turn-Mill Machines

Introduced to the turn-mill machine tool design in about 1996, the Y axis was first used on a single-spindle, mill-turn lathe with a subspindle. The idea of a Y axis on a CNC originated from the quality limitation of polar interpolation and the difficulty in programming, not from electronic advances in controls or servomotor technology as one might commonly think.