Hitting the Coolant Sweet Spot

Toolholders with integrated cutting fluid delivery channels offer threaded, fixed-position nozzles that direct parallel streams of coolant to pre-defined positions at the top of the cutting tool.

Lathe operators once relied on flood coolant to keep cutting tools cool and the workzone lubricated and free of chips. With the advent of CNC machines, through-the-turret cutting fluid and tooling blocks with adjustable coolant balls have become the norm, but these often make it difficult to aim the fluid where it’s needed most—directly at the tip of the insert.

Some shops opt for short lengths of copper tubing that are attached to these balls to redirect the coolant stream around the back of the toolholder or over the top of the clamp. These systems are time-consuming to set up and often difficult to get in precisely the right spot. A modular plastic hose is much simpler to use, at least until the operator’s back is turned and a stringy chip knocks the hose out of position, scrapping the workpiece and possibly destroying the toolholder in the process.

Featured Content

Ditching the Coolant Lines

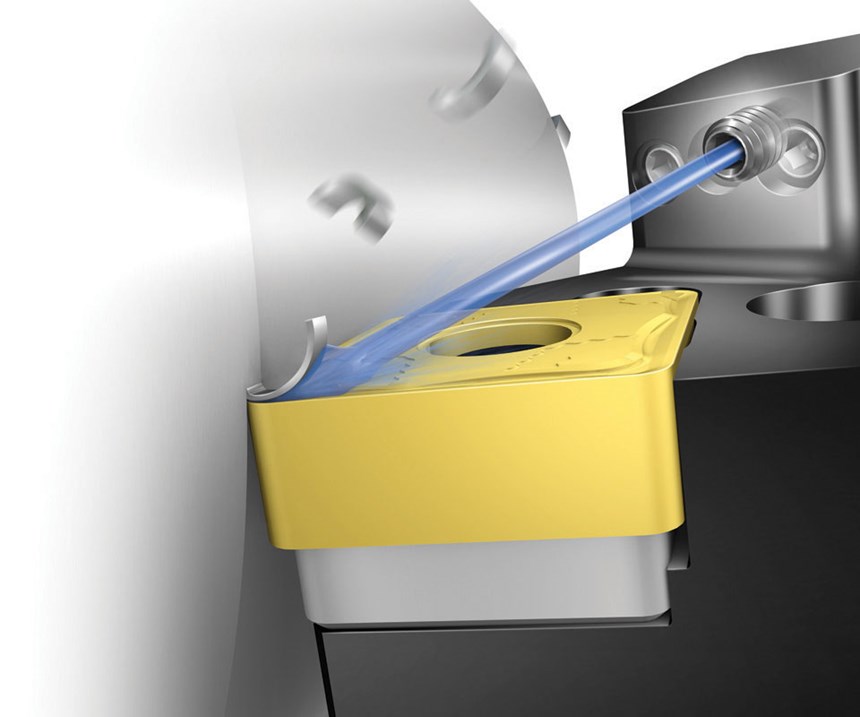

Thanks to toolholders with integrated cutting fluid delivery channels, this “spray and pray” approach has largely been eliminated. Sandvik Coromant’s CoroTurn HP toolholders offer threaded, fixed-position nozzles that direct parallel streams of coolant to pre-defined positions at the top of the cutting tool. This setup eliminates the hassle and lost time that comes with flexible tubing use while improving chip flow, lubrication and heat removal.

CoroTurn HP and comparable toolholders also support high-pressure coolant (HPC). When combined with precision cutting fluid placement, HPC not only helps to break chips, but also brings far higher cutting speeds and extended tool life to many machining operations.

Despite these obvious benefits, however, Sandvik Coromant has found that the top of the insert isn’t always the best location for cutting fluid delivery. Much of the heat produced during metalcutting flows down into the insert, leading to plastic deformation of the substrate and its eventual collapse. Unfortunately, many modern tool coatings (AlTiN is one) require a certain amount of heat to function properly. Without high cutting temperatures, chips tend to stick to the insert surface, creating built-up edge (BUE) and subsequent chipping of the insert when the workpiece material breaks away.

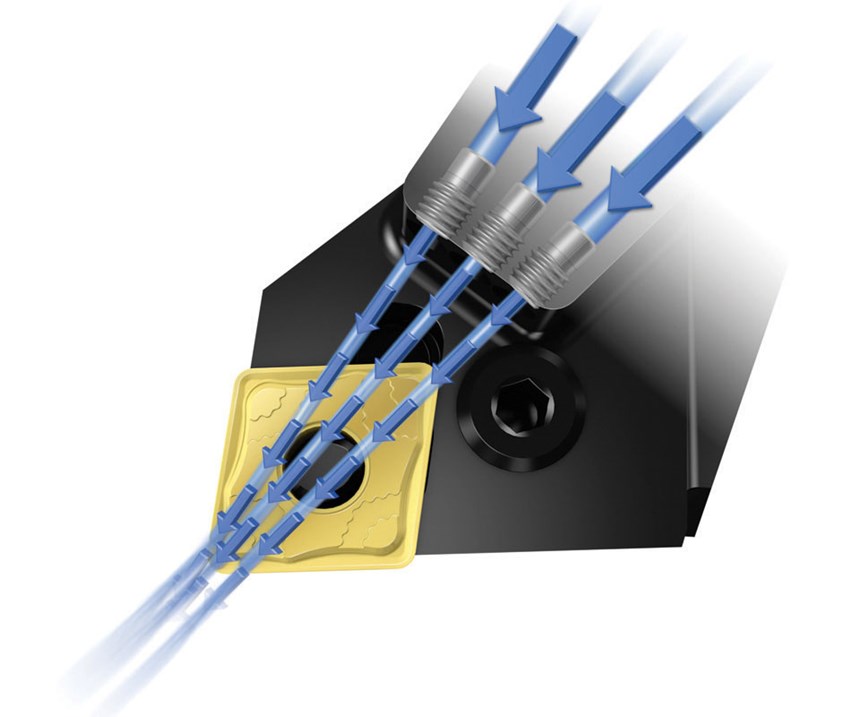

By introducing coolant to the bottom of the insert, cutting tool engineers have discovered that the carbide substrate can be kept cool while still allowing sufficient heat generation up top for the coating to do its job. This design enables higher cutting speeds and better tool life, especially during roughing operations, in which temperatures are highest. And by adding a separate stream of cutting fluid to the top of the insert, chip control and part surface finish is improved during finishing.

Sandvik Coromant calls this technology CoroTurn 300, a flexible facing and longitudinal turning solution for finishing to medium roughing applications in steel and similar materials. The new system is equipped with high-precision coolant ports at the top and bottom of the toolholder, either or both of which can be activated via a threaded plug arrangement. Even without HPC, this style of accurate top and bottom coolant delivery can improve productivity and tool life. A variety of geometries and coatings are available, and the insert has eight cutting surfaces, making it one of the lowest cost per edge turning tools on the market, according to the company.

Keeping it Cool

Coolant-capable cutting tools and toolholders are only one piece of an optimized cutting fluid strategy; without well maintained cutting fluid, even the best tool is bound to fail. That’s why machine shops must abide by the following good housekeeping practices to get the most from this often neglected aspect of metalcutting:

- Assuming the use of water-based or synthetic cutting fluids (not oil), every machine should be equipped with an oil skimmer. These low-cost devices continuously and automatically remove the tramp oils that cause dermatitis and bad smells, and they extend the life of cutting fluids. If unpleasant odors do crop up, a bactericide can be added to the sump to kill off any microorganisms.

- Sumps should be cleaned every few months or more often under harsh conditions. A sump sucker or equivalent device is an excellent way to filter out the metal fines, sludge and other contaminants that degrade cutting fluids, and they do so while minimizing machine disruption. Also, clean cutting fluids last longer, produce better parts and are often less expensive to recycle. (You do recycle your coolant, right?)

- Regularly check the pH and concentration levels of cutting fluids, adjusting them according to the manufacturer’s recommendations. Slightly higher concentrations can be used with difficult materials such as Inconel and Hastelloy, while lower concentrations will be more effective at heat reduction in aluminum and other nonferrous metals.

High and Dry

Sometimes, the best solution is no cutting fluid at all. Short chipping materials such as gray or malleable iron are typically cut dry, often using ceramic, cermet or CBN cutting tools. Steel forgings and similar gummy materials with which fine surface finishes are difficult to attain are another candidate for dry cutting, provided acceptable tool life can be achieved. If not, coolant may be the better option. In either case, it’s a good idea to keep an eye on the color of the chips—a good rule of thumb is purple for steels and light brown to amber on stainless.

In most machining situations, though, it’s tough to beat HPC. When equipped with the correct nozzle technology, a high velocity stream of cutting fluid blasts through the microscopic layer of steam that forms in the workzone. This process improves heat removal and helps thin the chip, allowing it to break more effectively. The result is a safer work environment and less downtime because of stringy chips wrapped around tools or jammed chip conveyors.

Sandvik Coromant estimates an ROI of a few months or less on a typical HPC implementation. Moreover, those shops looking to turn out the lights should take a hard look at HPC. It not only improves tool life and eliminates chip concerns, but also can produce a more stable and predictable process with higher speeds and feeds. Any shop using flex lines and flood coolant should consider ditching those hoses and bringing precision to the cutting fluids.

RELATED CONTENT

-

When Thread Milling Makes Sense

Threading a workpiece is a fundamental metalworking process that every manufacturing engineer takes for granted.

-

4 Strategies for Managing Chip Control

Having strategies in place for managing chips is an important part of protecting the production process, from tool life to product quality.

-

Skiving Long, Slender Parts with Tight Tolerances

Here's a look at one of the oldest and most efficient methods of screw machine production for parts that are long and slender, with close-diameter tolerances and finishes, or parts that require truly spherical radii.