Improve Productivity with Digital Tooling Data

This system seamlessly interfaces cloud-enabled digital tooling data and intelligence with production, inventory, and e-commerce to optimize shop productivity.

#Industry40

Technology suppliers are continually developing new methods for digital access to information. Taking it a step further, here’s a system that seamlessly interfaces cloud-enabled digital tooling data and intelligence with production, inventory, e-commerce and more to optimize shop productivity.

Data Collection

Featured Content

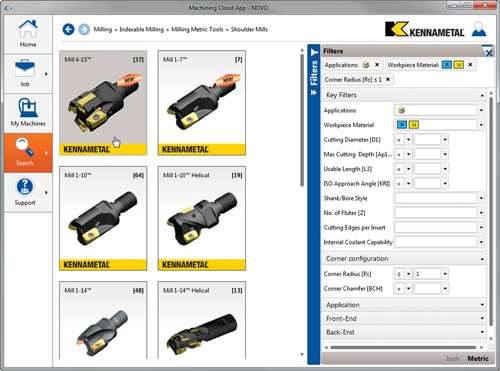

Kennametal’s Novo digital process planning application supplies complete tool data (milling, turning, holemaking, tools, toolholders, spare parts, speeds and feeds, and more), saving hours of catalog lookups and process guesswork for process planners, parts estimators and manufacturing engineers. Now, through an interface with Machining Cloud GmbH, that same intelligence brings additional part design efficiency in CAD/CAM, cutting simulations, presetting, inventory management and e-commerce. Novosphere has been developed to help feed these real and potential process improvements back into the shop based on actual data gathered from the shop’s equipment.

Built around the shop’s needs, from quotation to inspection, Novosphere implements specific stages to increase productivity:

Select and Advise Stage: Users evaluate machining strategies based upon machine, material, part features, and specs, determining the best machining approach and requirements for time, cost and tools.

Simulate Stage: Users simulate the entire process from start to finish to find dimensional issues and possible collisions.

Inquire and Purchase Stage: Users investigate what they already have to perform the job and the availability of what needs to be purchased.

Optimize Stage: Users determine the effectiveness of the plan, whether or not it is meeting time and cost requirements, and whether or not it is repeatable for future applications.

Optimization

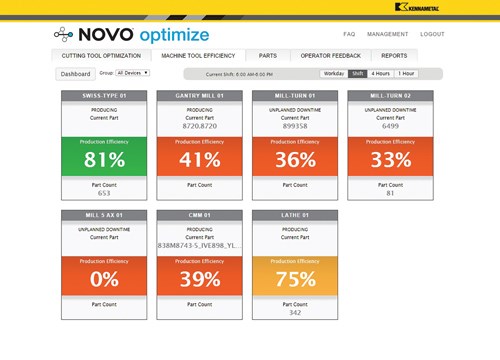

Novo Optimize is the latest manufacturing intelligence application in Novosphere. It collects real-time data about how a shop’s cutting tools and machines are performing and also provides analysis of where process efficiencies or capacity can be improved.

Every shop generates a large amount of data that it could collect for its own continued improvement, but efficiently gathering the data from different makes and models of machines and tools can be difficult. All Novo Optimize data and process knowledge complies with MTConnect’s open, royalty-free communications protocol designed specifically for the shopfloor environment. It can draw data from machine tools, cutting tools, presetters or any piece of shop equipment or data source and automatically recommend process knowledge changes (speeds and feeds) or identify better performing tools based on the application’s needs.

“Each shop using Novo Optimize has improvement opportunities unique to it based on operator feedback and shop conditions,” says Colin Tilzey, director of Kennametal’s Innovation Ventures group. “Identifying sources of machine downtime combined with powerful, knowledge-based recommendations means the possibility for real, significant process improvement.”

How it Works

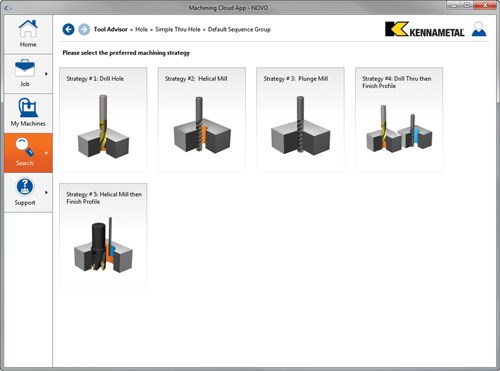

Novo can be used to help define machining features such as drilling a blind hole, and then immediately reduces the product choices to those that can do the job effectively. The system takes into account constraint requirements such as material, tolerance and machining sequence for both single tools and multi-tools. It then ranks the results—based on knowledge-based rules—to best meet the application challenges as defined by the shop’s operating environment and user preferences.

When a customer already has a preferred tool and grade in mind, smart attribute filters not only quickly select the products available to do the job, but the system also provides options regarding what cutting item and adaptive item fits and can be adjusted for the selected solution. Smart filters can help reduce the time it takes to select all cutting tool components from hours to minutes, providing users a comprehensive list based on their input. The Tool Configurator then provides CAD files and graphic support for the selected tool components and their assembly.

“Novo thinks like a process planner,” says Thomas Long, head of the Virtual Machining RDE department at Kennametal. “It works from the feature back to the tooling strategy. In addition, each order number is tied to application data gleaned from hundreds of subject matter experts and decades of Kennametal experience. Request a part number and you also get pictures, assemblies, and spare parts lists, as well as inserts that fit. It accomplishes in minutes what formerly took hours.”

The Job Functionality option is a cloud-based repository, linked to a user by a unique ID, where tool lists can be stored for future use, editing, copying and sharing. These lists can be downloaded into standard report formats that include tooling dimensional data, weights, speeds and feeds, and photo or CAD model images.

Addressing the Skills Gap

Manufacturing is expanding exponentially in developed and emerging economies around the world as major industries such as aerospace, automotive, energy and others consistently demand new and better products. Manufacturing technology providers have responded with computer-driven machine tools, digitally based computer-aided design (CAD), toolpath generation software (CAM), and significant advances in tooling. Yet behind this positive outlook lies a major barrier threatening this scenario: a significantly widening skills gap as older workers retire and new workers fail to engage in manufacturing careers.

Novo is designed to help address the issues of the skills gap through distribution of knowledge. “More than a catalog, Novo brings users into a community—all our ongoing expertise delivered in a digital means of accessing process knowledge quickly,” says Francois Gau, VP of strategic marketing and new business development, Kennametal. “The result empowers users by providing the right solutions specifically tailored to their operations. It solves problems instead of managing data.”

RELATED CONTENT

-

How to Get More Efficient Production from Swiss-Type and Multitasking Machines

SolidCAM for multi-axis Swiss type and multitasking machines provides a very efficient CAM programming process, generating optimal and safe Mill-Turn programs, with dramatically improved milling tool life.

-

Adding 5-Axis Capability to a 3-Axis CNC Mill

This attachment provides shops using thee-axis machining centers the option of on-demand four- and five-axis machining.

-

Keeping Watch on Small Parts

From watch parts to exotic medical applications, this shop takes on the world of micromachining.