Making Locks Since Lincoln

For 150 years, padlock manufacturer Wilson Bohanan has done one thing and done it well. Spanning much of the Industrial Revolution, this company has survived and prospered by adapting to change both in product and process as evidenced by the company’s recent installation of a CNC multi-spindle.

In 1860, Wilson Bohannan and his son started a padlock business in a Brooklyn, New York, garage. Since then, with a location change to Marion, Ohio, in 1927, this seventh-generation, family owned and operated business has made the solid brass WB padlock.

It found early success supplying all-brass padlocks for the growing railroad industry to secure freight cars, track switching gear and other outdoor applications where a rustproof padlock was mandated. By the turn of the 20th century, utilities, gas and electric became a growing market for WB locks for the same reason.

Featured Content

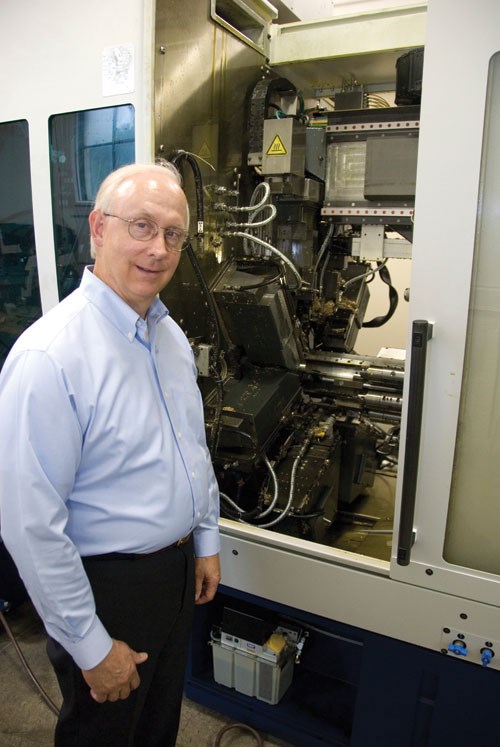

“When you’ve been around as long as WB, you’re going to see some industries born, grow, mature and, in some cases, decline,” says Howard Smith, the company’s president and member of the sixth generation. “You have to be able to adapt to survive and our family business has successfully managed to do that.”

Today, the company supplies its locks to government and military installations, refineries and manufacturing operations. Its 62 employees manufacture more than 5,000 locks a day in its Marion facility.

Rebuilding the Business

Mr. Smith joined the company in 1973 and took the reins as president in 1995. For the last 15 years, he has re-focused the manufacturing arm of WB by investing in new technology, equipment and automating processes where automation made sense.

This rededication to in-house manufacturing was a result of competitive pressures and the strong desire on Mr. Smith’s part to keep WB products completely made in America. “In the late 1960s, we, like many manufacturers, began off-loading our manufacturing capability,” Mr. Smith recalls. “So by 1968, we sold our lock making equipment to another company to make the parts for us. It was outsourcing, but back then, it was outsourced domestically. By the time I came on board in 1973, we pretty much just assembled our padlocks.

“The thinking of many businesses at that time was why invest in manufacturing anything?” he continues. “So for about 20 years, we farmed out our manufacturing and simply assembled our locks.”

By the 1980s, WB’s margins began to shrink, and there were quality issues. To remain competitive and grow the business, the company made the decision to re-introduce manufacturing to the company.

“We began buying machinery for ourselves, and phased out the relationship we had with a company that was manufacturing for us,” Mr. Smith says. “It also became evident that if we were to remain American made, productivity and process improvements had to be made in the form of high-tech equipment. That commitment is manifested in the new Tornos Multi Alpha 8 × 20 we bought last year and our continuing search to find better ways of making our products competitively.”

Mass Customization

In a way, lock making is akin to watch making. It tends to be a very specialized kind of manufacturing that often requires specialized machinery.

There are 34 component-machined parts that go into the WB padlock. However, the variations of these basic components that a customer can order take the possible permutations to the hundred and even thousands. As a result, WB makes its locks to order, which leads to a need for a streamlined production process. It’s not mass production—it is mass customization.

While some might look at WB as an OEM because it makes a product, Mr. Smith operates the shop like a job shop. It is set up to respond to incoming orders rapidly and efficiently, using a pull-through production system.

“Even though we have invested in automation using robotics, CNC machine tools, automatic material handling and custom assembly machines—many made in-house—it is not our goal to remove the human element from our manufacturing equation,” Mr. Smith says. “I want people involved in our manufacturing process. We use the automation to help them do their jobs more productively, and that’s where the direct cost savings come into play.”

Many of the machines used in the assembly area were designed and built in-house. The shop’s V.P. of engineering, Mark Williams, is responsible for many of these. He’s a 34-year veteran with WB.

“Some of the equipment we built for our own use simply because nothing like them is available commercially,” Mr. Williams says. “I use Solid Works to design the machinery, and we have managed to automate several previously manual assembly processes that have dramatically improved throughput and quality. During the design phase, I work with the assembly personnel to get their input, and the result is an effectively personalized machine ergonomically designed for the employee using the machines. It gives them ownership and makes their jobs easier—a win-win.”

To make the point about WB’s ability to customize, both my photographer and I were presented with padlocks engraved with our names, which were made during our visit.

Enter the CNC Multi-Spindle

One of the last pieces in Mr. Smith’s long road to manufacturing self sufficiency was a lock barrel (generally called a plug) that had been outsourced domestically. It was the last component part not made by WB.

The decision to bring this work in-house opened up opportunity as well.

In his search for technology that could provide the shop with lower costs for the outsourced parts and additional capacity for making more different parts as well as production and quality control, Mr. Williams looked at the CNC multi-spindle. “My alternative was to put in a bank of single-spindle machines,” he says. “Instead, I chose to consider this machine as eight single-spindle machines on a single platform. Larger floor space requirements, longer complex setup and tear down time, longer cycle times for single-spindle machines all lead me to the multi. It could make parts fast, complete and at a fraction of the cost we were paying. The decision was a no-brainer.”

Because WB makes to order, lot sizes can be relatively low. Quick change-over is one of the CNC multi’s strengths, especially when being used for families of parts that are similar, like lock cylinders. “Sometimes change-over from one part to another is a simple programming change,” Mr. Williams says.

The manufacturing arm of WB is set up to make any lock in the company’s catalog. With a pull-through, on-demand system, lot sizes can be 500 or 5,000 depending on the lock. So the ability to change back and forth quickly was key to run variable quantities quickly, and then change-over.

He settled on the Tornos MultiAlpha 8 × 20. Quick specs: It’s a 20-mm, eight-spindle with a maximum main spindle speed of 8,000 rpm, 10,000 rpm for the counter or pick-off spindles. All of the spindles are independently programmable. It has 26 programmable linear axes and 10 rotational axes. Backworking tools available are 2 × 5 for a total of 10. On the WB machine, some of the options include a Y axis on two endworking slides and Y axis on two cross slides. “Several of the parts need off-center drilling so the Y axis is a huge plus,” Mr. Williams says. “It has a lot of bells and whistles.”

But one of the machine’s features really sealed the deal for Mr. Williams. This machine uses two programmable gantry mounted pick-off spindles. These dual pick-offs were originally designed to reduce cycle time for backworking operation, which often controls the cycle time for a complex part by dividing the backworking time in half. But it also affords an additional benefit of running two simpler parts at one time.

Two by Four

Double drop (or as Tornos calls it, 2 × 4) has been a production technique on multi-spindles for years. Obviously, making two parts at a time is more productive than one. However, this was generally confined to primary machining operations with backworking usually requiring a secondary operation.

The dual gantry pick-off spindles allow WB to make two parts at a time complete, including backworking. Each subspindle is capable of 10,000 rpm and can access five backworking tools, three of which can be live.

One example that was running on the day of our visit was a plug being produced using the 2 × 4 technique. Mr. Williams said he’s getting two parts in 11 seconds compared with one part in 45 seconds on the single-spindle that previously ran it.

With this method, stations 1, 3, 5 and 7 are available to make one part and 2, 4, 6 and 8 are used for the second. That gives primary machining on three stations for each part; the fourth is used for cutoff. Once cut off, the dual pick-off takes the part to the backworking stations.

When complete, the pick-off hands off the parts to a manipulator (simple robot) that discharges them to an external chute. Normally, this manipulator uses grippers sized for parts, but WB’s machine uses two baskets to convey the parts, which simplifies change-over.

Change-over on this machine from 2 × 4 production to classic 1 × 8 can be as short as 15 minutes. In the 1 × 8 configuration, the dual pick-off spindles take a part from stations 7 and 8 to backwork two parts at a time, halving the backworking cycle time. For high mix, complex and simple parts, like WB makes, this flexibility is very handy.

Welcome Back

Mr. Smith is bullish on American manufacturing. Through the prism of his company’s long history, many changes, good and bad, have occurred to our nation’s manufacturing base. He is also an optimist; he sees the trend of re-shoring as encouraging. However, the erosion of domestic infrastructure is a concern.

“Many of the businesses that supplied our manufacturing base are gone,” he says. “This infrastructure must be rebuilt, which is an opportunity for companies like us, and one reason for adding capacity with machines like the Tornos. As we see labor rates rising in Asia and secure lines of supply being vulnerable to strikes, political upheaval, and even the weather, it’s clear WB made the right decision to invest in domestic manufacturing.”

He continues, “I see many of my colleagues that jumped on the outsourcing bandwagon coming back, and I welcome them. Competition is good for us. It makes us better. It’s also an opportunity for us to really be a job shop by making parts for them that they previously had made elsewhere. Our commitment to invest in our manufacturing capability makes us part of the infrastructure renewal.”

RELATED CONTENT

-

Dry Swiss Machining in Medical

Continuing to build its reputation for creative solutions, this multi-faceted medical device component manufacturer took its Swiss machining operations to a new level to meet a customer’s market demands.

-

VIDEOS: Tips for Screw Making on Swiss-Type Machines

Here’s a three-part video series focused on Swiss screw making to help explain the benefits of thread whirling, back turning and broaching while taking into consideration CAM programming, tooling and machine specifications.

-

Making Parts on a Swiss/Laser Machine

Adding laser cutting to Swiss-type machining is helping this shop do more work for its customers in the medical industry.