Making Stainless More Machinable

This article gives tips on how to further the enhancement of stainless steel machinability.

#basics

Stainless steels are one of the more difficult materials to machine. The addition of sulfur to ease machinability, as in austenitic grades such as 303, are still prone to built up edge, difficulties in maintaining a good part surface finish and reduced tool life. Reducing this sulfur addition as needed in 304 and 316, make these matters even worse and adds reduced chipping tendency to the list. Alchemists have searched high and low to find the recipe that turns lead into gold. Steel producers searched for a formula for stainless steels that would make these materials friendlier to machinists.

Back in the early to mid 20th century, metallurgical scientists discovered the usefulness of sulfur in stainless steels. They found that sulfur forms compounds in the stainless steels that will help break the stainless steel chip during machining and form a lubrication layer on the top of the cutting tool, reducing friction and extending tool life. The use of sulfur expanded throughout the stainless industry to give rise to free machining grades such as 303, 416 and 420F.

However, there is a dark side to these high sulfur additions. Sulfur attacks the good attributes of stainless steels. Corrosion is compromised, interferes with welding and can become an initiation site for cracking to occur, especially when any deformation is performed on the part or when there are thin wall sections. The use of sulfur also found its way into other common stainless grades—410, 304/304L and 316/316L to name a few. The adverse effects of sulfur in these grades are not as pronounced on properties as the free machining grades. Welding, corrosion resistance, ductility are generally not an issue. These small sulfur additions do have a substantial effect on the machinability of the stainless steels, as a 0.005-percent increase can increase machinability by 50 percent or more.

Modifying chemistry and/or changing manufacturing process parameters can provide modest gains in machinability, but these are still the limitations sulfur provides at the higher machining speeds.

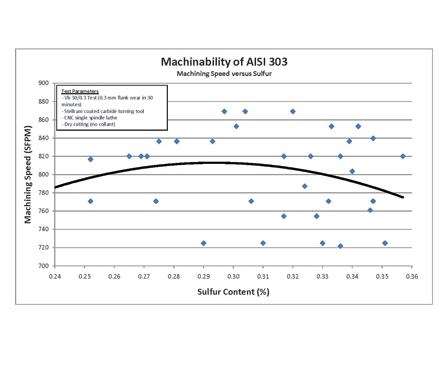

So how does one further the enhancement of stainless steel machinability? One way is to maximize sulfur levels. Technical literature and industrial studies, however, seem to indicate that sulfur has diminishing returns on machinability with increasing sulfur levels. Figure 1 shows machining data generated by stainless manufacturer, Ugitech, for 303 at varying sulfur levels higher than 0.15 percent. This graph validates published literature to show that more sulfur, especially at levels beyond 0.30 percent, shows a diminishing return for machinability. The main culprit is the loss of lubricity at the elevated machining temperatures or machining speeds. At that point, the sulfur acts mainly as a chipbreaker and stops lubricating the tools. Sulfide size and distribution factors also play into machinability.

Modifying chemistry and/or changing manufacturing process parameters can provide modest gains in machinability, but these are still the limitations sulfur provides at the higher machining speeds. At its research center in France, Ugitech took a different approach and found a way to reformulate the stainless steels without affecting the mechanical and physical properties. This reformulation changes the hard abrasive oxides that normally exist in all stainless steels to create a “high temperature lubricant” to coexist with sulfur, achieving higher machining speeds.

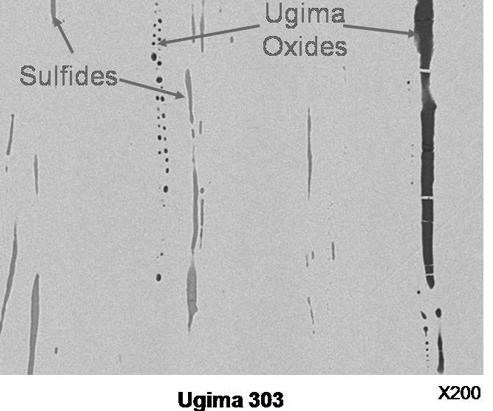

In every heat of stainless steel, various oxides, such as those in Figure 2, exist as hard and abrasive particles. These oxides, in contact with the cutting tools during machining, cause tool wear and additional heat, leading to premature failure of the tooling. However, if these oxides were changed into ones that are ductile and malleable, these new oxides provide a substance that has high temperature lubrication properties and will act as additional chipbreakers. Ugitech named this controlled oxide Ugima.

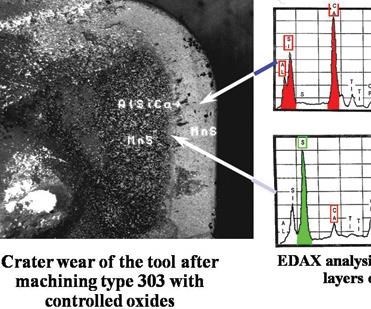

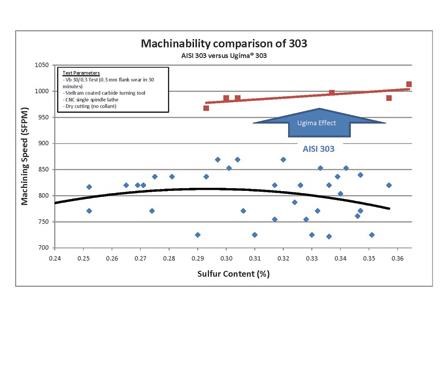

These claims become evident when you see these oxides elongate much like sulfur during the hot rolling process (Figure 3). This claim is further validated by X-ray chemical analysis of a tool surface (Figure 4). Both manganese sulfides and the controlled oxide chemical signatures are found on the tool surfaces. This all translates to a 25-percent higher machining speed capability based on 303 stainless machining tests (Figure 5). One additional observation, the machinability of the Ugima 303 does not taper off as the AISI 303, leading to a synergy found between the controlled oxide and sulfur.

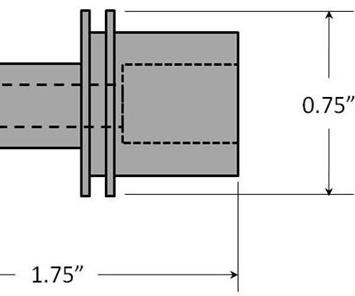

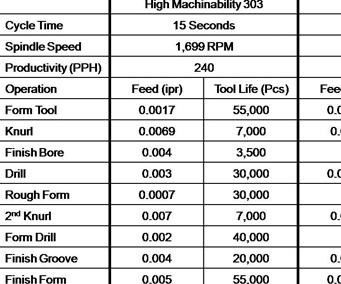

One case study to exemplify the machinability of theses grades is a 303 job illustrated in Figure 6. Made from ¾-inch round 303 on a Schütte CNC eight-spindle multi, the part is complex with several slotted grooves on the surface as well as two straight knurls in both outer diameters of the part. The holes are both drilled and reamed, and during the transition to the 303 Ugima bars, the customer added an internal thread. Upon completion of the machining optimization, the customer was able to decrease cycle time by 45 percent to 8.3 sec. (Table 1), giving them a 74-percent increase in parts per hour. As an added benefit, most of the tooling experienced increases in life. This translates into a cost savings of $0.24/part (given a $100/hr. machine cost at 80-percent efficiency) and an 81-percent increase in the parts per hour.

Consistency is another important attribute in machining and is just as important as reducing cycle time.

Consistency is another important attribute in machining and is just as important as reducing cycle time. Machinists do not want to set up the machine for a new bundle of stock. The Ugitech mill has developed manufacturing methods to provide the best product for their machining customers, allowing very little variation—every order used in a machine shop should see the same machining behavior heat after heat, order after order.

The best example of this consistency is a shop that used 316/316L Ugima for a small job that came around once a year. The shop optimized their setup on the material and made the parts. One year later, the customer purchased another bundle of 316/316L. Using the same tools, machine, CNC code, and so on, the job was not running well. After some digging, the shop found that it replaced the “same” coolant from another manufacturer. Once the original coolant was replaced, the job was running as before. This type of consistency is valued by both shop owners and machinists.

Ugitech’s controlled oxide, high machinability stainless steels are available in the common stainless grades. This technology, along with consistent manufacturing and combined with technologies such as SMQ (Swiss Machine Quality—a precision cold drawn bar with Swiss tolerances and superior bar straightness), is resulting in drastically reducing machining costs and remaining cost effective in this highly competitive market.

RELATED CONTENT

-

Cutting Tool Coating Production

This article looks at the coating methods available for carbide cutting tools.

-

Understanding CNC Collet Chucks

Workholding for turning is usually fairly basic: The selection comes down to chucks or collets. This article looks at when to consider the collet chuck and what kind might be best for a given application.

-

7 Causes of Quench Cracking in Steel

Failures of steel parts in service or production occur infrequently. However, when steel parts fail, the consequences are dire. Here are seven ways that steel can fail as a result of quench cracking from heat treatment.