Mill/Turn Centers Spur Shop's Growth With Increased Uptime

After adding a 12,000-square-foot addition onto an existing 32,000-square-foot facility, the management of Nolte Precise Manufacturing (Cincinnati, Ohio) is in the mindset to expand its business and improve its processes, allowing it to grow not only in square footage, but in machining capability as well.

After adding a 12,000-square-foot addition onto an existing 32,000-square-foot facility, the management of Nolte Precise Manufacturing (Cincinnati, Ohio) is in the mindset to expand its business and improve its processes, allowing it to grow not only in square footage, but in machining capability as well.

Although the 90-year-old company houses between 50 and 60 workcenters, including almost every type of metalworking machine necessary to satisfy its customers—multi-spindles, screw machines, single-spindles, secondary equipment, grinders, broachers, chuckers, CNC Swiss machines, CNC lathes, CNC mills—President Bob Coster and his son, Vice President Doug Coster, were looking for a machine that offered better milling capability than the machines they currently own. Bob was certain that this upgrade would help deliver quality parts faster. “The technology has changed in regards to live tools, in terms of engagement time and horsepower from earlier models. It’s now more practical than ever to do the part complete and not sacrifice cycle time,” he explains.

Featured Content

With customers in markets such as hydraulics, aerospace, automotive, Department of Defense, marine and home construction, the father and son team kept this customer base in mind while searching for a new machine to make their metalworking processes more efficient. They began by exploring all the options available to them, and specifically, they were looking for three characteristics in the machine tool: equipment reliability, service capability by both the manufacturer and the distributor and exceptional equipment cycle time.

While visiting the 2005 Precision Machining Technology Show (PMTS), Bob and Doug assessed many machines, including a Eurotech turn/mill center from Eurotech Elite (Brooksville, Florida). “Being at the show was critical in our review process,” Bob says. “We were impressed when we saw the machine in action. We were impressed with the standard features and that it was built from the ground up as a bar machine. It appeared to be faster than the other machines we looked at, too.”

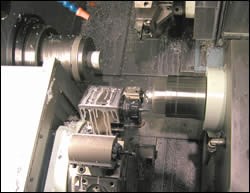

After the show, Doug reviewed all of the equipment again and received cycle time estimates on specific parts from several prospective machine builders. Based on all of the factors—including the fact that the Eurotech cycle time estimate was significantly faster than the others, according to Doug—the Costers chose to purchase a turn/mill machine from the company because it offers two turrets, live tooling and more than 3 inches of bar capacity. “The extra bar capacity gives us the flexibility to offer our customers quick turnaround times and reasonable prices on a range of part sizes,” Doug explains.

“We were looking for subspindles, independent turrets and live tooling,” Bob says. “When reviewing the machine at the show, we also liked that it was compact.”

Since the purchase, the shop has seen an increase in efficiency by implementing the new machine. To begin with, the actual cycle time on the quoted part was exactly the estimated time of 54 seconds. “All of the cycle times have been right on,” Doug says. “This was 20 percent faster than we were able to run on our existing six-axis equipment. On other parts we have converted, we have been realizing 20-percent improvements without changing anything.”

A few months after the initial purchase, the shop purchased another turn/mill center, only this one had a Y axis on the upper turret for a total of seven axes. “The Y axis gives us even more flexibility to serve our customers. We can do more of their parts complete,” Doug explains. “Our customers’ parts are continuously getting more diverse. Therefore, we need the machines to have more capability than ever before.”

The Eurotech machines, which are used to machine aluminum parts at the shop, have multitasking capabilities that have increased uptime at Nolte. “We produce an end cap that is turned, threaded and bored and recessed at both ends,” Bob explains. “We are also doing hydraulic piston-type parts that are bored, counterbored on both sides, cross drilled and milled. We used to put this job on a screw machine, then a CNC lathe and then a vertical machining center. Now, we simply put the bar in one end of the machine, and a part comes out in the box. These machines allow us to service our customers with quick leadtimes and turnarounds. We can reduce inventories as well. Now, we may run a job in 1 to 3 days at the most, where it used to take 6 weeks. Then, after the parts were machined, we had to do something different to each part. The idea of ‘from bar to box’ is a major inventory savings because of the setup time.”

Because of its likeness to other machines that the shop’s operators are accustomed to operating, the Eurotech was an easy transition for the shop to make and required little to no training. The machine is programmed the same as the shop’s older CNC machines, and it reads the G codes and the speed of the movements like other machines as well, according to Bob. In fact, the shop’s operators had the machines up and running the same day they were installed, Doug adds.

Once these machines are set up, most operators in the shop are eager to work on the new equipment. The machines recruit employees to run jobs simply by their existence in the shop. “The operators really like the controls, the cleanliness of the machine, the features, the blinking lights,” Doug explains. “Not only are they good for the production side of the business, but also employee retention.”

Although increased efficiency and ease of use are significant benefits to the machine tool purchase, the support Nolte Precise’s distributor provides also makes the machine worthwhile. Bob and Doug have had some bad experiences with distributors, so finding a reliable one that would fit their needs was priority for them. In fact, the Costers point out that without good support, the machine is worthless. Their distributor, Superior Equipment Solutions (Springboro, Ohio), takes care of Nolte’s concerns immediately. “The company (Superior) works well as a team,” Bob says. “Sometimes the salesman visits us just to make sure everything is fine. If we have a service issue, they know about it. They are good at communicating and are very proactive. They keep us apprised of any issues that might come up. We don’t have to call them to ask what is going on.” He adds that Superior not only supports the Eurotech machines, but other machines in the shop as well.

With the help of these new machines that are producing results for the company, the Costers are thinking forward. “We have some shaft work that we are looking at that, if it works out, we might run on this machine,” Bob says. “We have some steel parts that we may run on it as well.” Doug adds that he definitely sees continued use of these machines in the shop’s future.

Bob and Doug are now more comfortable looking ahead knowing that there is room for more machines when the time comes, thanks to the recent addition to their facility. Where the shop was once “almost stacking machines on top of each other,” the new area of the building now provides plenty of space in which operators can run the machines, including the two latest purchases. With this new-found space, Nolte Precise has room to not only expand its business, but improve efficiency as well.

RELATED CONTENT

-

Making Parts on a Swiss/Laser Machine

Adding laser cutting to Swiss-type machining is helping this shop do more work for its customers in the medical industry.

-

How Advancements in CNC Multi-Spindles Can Put You Ahead of Current Trends

Growing economic and labor pressures are making CNC multi-spindle turn/mill technology more viable than ever. This real-world comparison to a single-spindle lathe shows how.

-

Turning to an Adhesive for Lathe Workholding

Adhesive cured by ultraviolet light is an option for securing parts for machining that could otherwise distort when traditional, mechanical clamping techniques are used.