Optics Maker Focuses On Flexible Production

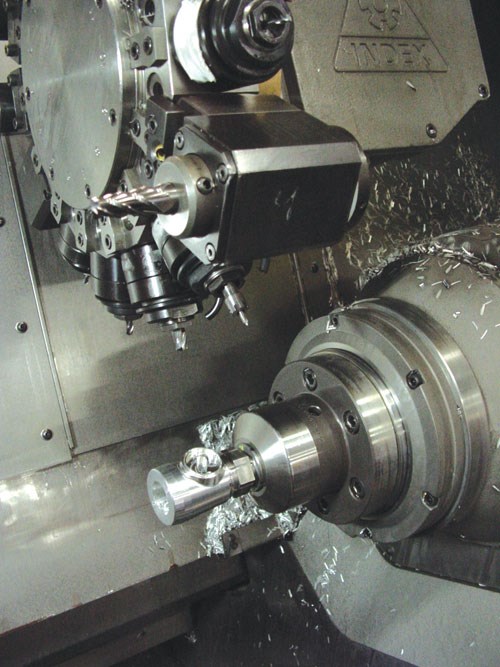

Leupold & Stevens has found the key to successful precision machining. It operates more than 30 Index machines, primarily multifunction turning machines used to produce the bodies and tubes for the rifle scopes from aircraft-quality aluminum.

Leupold & Stevens (Beaverton, Oregon) is a designer and manufacturer of sport optics and tactical optics. Its rifle scopes typically have more than 60 parts each, including the lenses, and are hand assembled. When they leave the factory, they look like jewels. And they come with a lifetime warranty.

To create a successful product like a Leupold product, the company, which celebrated its 100th anniversary in 2007, has found that investing thoughtfully in machines and people is essential. Most of its 675 employees have been with the company for more than 10 years, and some have been there much longer than that.

As for Leupold, it has found the key to successful precision machining. It operates more than 30 Index machines, primarily multifunction turning machines used to produce the bodies and tubes for the scopes from aircraft-quality aluminum.

Featured Content

The company bought its first Index machine in 1957, a cam-operated turret machine, to make scope tube parts. Since 1989, 90 percent of its machine inventory has been converted to CNC, including four CNC multi-spindle machines. Leupold also has on its floor Index ABC turning machines, G200, G250 and G300 multifunction turn-mill machines. It is a sea of blue-green turning, milling, drilling and tapping of more than 1,000,000 pounds of aluminum each year. Tolerances in some applications are less than 0.0005 inch, but almost always at least ± 0.002 inch.

“There is a technological partnership between Index and Leupold that has helped both sides develop their respective products,” observes John Karge, manufacturing engineering supervisor at Leupold. Employees on both sides work together in a mutually respectful and productive way, according to both companies. That forms a foundation for many improvements in the machines and processes. And with literally hundreds of products and variants, the challenge to improve is always there.

Almost 600 different parts go across the 30 Index machines. Average setup time is 4 hours, including the CNC multi-spindles. Each machine produces about 20 different parts. Typical runs require a machine to be set up once or twice a week, sometimes four times, so Leupold has worked hard to pare down change-over times to a minimum.

“Our work-in-process turns have increased, and our inventory has decreased, so we have very few parts sitting around. One of our goals is to keep the machines cutting, not sitting idle while they are being set up,” says Dave Sonsteng, Leupold parts manufacturing manager.

One way Leupold keeps the machines producing quality parts is through the Index tool management system and preset tooling. A Zoller presetting system is used to measure all tooling. Tool data and programs are then downloaded directly to each of the machines on the floor.

Another key to keeping the machines producing parts at Leupold is through the use of the Index P200 programming system. This system organizes programs and tooling for each machine on the production floor. Programming and tool preparation is done offline prior to shutting a machine down for setup, minimizing downtime. Once set up, the programming system manages the operation and automatically provides the dialogue programs for the machine setup.

To set up each part, the operator presses “cycle start” and looks at the tool list on the screen, reaches into a drawer, chooses the correct preset tool and inserts it into the machine spindle or turret. It takes only 15 minutes. This way, the machine is ready to turn perfect parts the first time. The first part off is to print. There is no time wasted in trial cuts. This puts Leupold ahead of 98 percent of job shops in the United States, according to Index Corp.

Process control on the machine is also evident at Leupold. The reliability of the process on each machine is monitored closely, so unacceptable parts are not produced.

When a unique part or process idea comes to Mr. Karge, he begins to think about how best to make it. He consults with Index engineers, gets their input and adds his considerable experience to the mix, including sometimes adjusting the part design to get the most cost-effective method. It takes a partnership to develop a process that is cost-effective and user-friendly, he explains.

“In 1995, we went to Index to test main tube machining methods on different machines, which led to the purchase of four G300s,” Mr. Karge says. “Index has been doing the job for 12 years now. That got us into the one-piece main tube production.” Leupold is still successful in creating two-piece main tubes using other Index machines as well.

Today, Leupold & Stevens has honed its expertise at machining long, thin-walled parts, and it has become one of the company’s most valuable capabilities. But not without the development of the process with the Index RatioLine G300 multitasking turn-mill center.

The Index G300s, with the capacity to turn lengths as much as 49 inches (1,250 mm), have allowed Leupold & Stevens to machine a range of 7- to 13-inch scope bodies in one cycle.

“The Index part handling system and the fact that the parts can be removed gently from the machines is a very important factor for us,” Mr. Karge says.

The combination of the Index machine capabilities and the processing expertise of the engineers at Leupold & Stevens are two major factors in the success of the optics manufacturer. But there is one more important factor: Both companies benefit from having a similar culture, according to Mr. Sonsteng.

“The culture of the two companies is similar in our dedication to providing quality products and service to the customer, and that has helped to strengthen our relationship and provide an advantage to us,” he says. “That relationship plus the quality of the machines is why we continue to invest in Index machines and software. A lot of trust has been built through the years.”

RELATED CONTENT

-

A New Approach to CNC Turning

This turning process takes advantage of a turn-mill’s B-axis spindle to vary a tool’s approach angle to optimize chip control and feed rates.

-

6 Tips for Training on a Swiss-Type Lathe

There are nuances to training a person to effectively operate a Swiss-type lathe. A shop I visited a while back offers some suggestions.

-

Turning to an Adhesive for Lathe Workholding

Adhesive cured by ultraviolet light is an option for securing parts for machining that could otherwise distort when traditional, mechanical clamping techniques are used.