Parts Cleaning in a Vacuum

While not glamorous, cleaning is a necessity for quality parts production. This supplier provides a solution to many of the issues shops face for fast, effective and environmentally friendly parts cleaning.

When a shop is considering the purchase of a new machine, it’s easy for the personnel to get excited. Newer technology. Faster production. Better quality. These features can bring images of a new high-precision turning center or perhaps a turn-mill that will allow complete part production in a fraction of the time. Depending on the application, the new equipment could take the form of any number of things, but the excitement is typically reserved for those machines that will directly produce parts.

So what about a parts cleaning system that can be equally effective in bringing such benefits to the shop floor? Unfortunately, the lack of glamour in an operation such as parts cleaning often detracts even from the potential benefits it can bring to the bottom line. It’s an operation that sits in the background of the profit earning powerhouses, yet it, too, can have quite a substantial impact on a company’s earnings.

Featured Content

Effective parts cleaning is a challenge 100 percent of the shops face. The differences lie in the level of cleanliness required and the quantity and size of the parts. It’s with these variables in mind that shops must determine the best cleaning solution for their applications.

As customer requirements are pushing shops more toward smaller increments of capacity, with an increasing need for dropping parts complete, batch processing in production is often being minimized. But as the parts come off the machines, many times they are then batched in the back of the shop, awaiting cleaning in larger quantities. It’s a conflict that one supplier was noticing across its customer base.

Suitable Partners

Gosiger Inc. is a distributor of machine tools and accessories with the clear objective of helping manufacturers improve their processes so they can be more competitive and profitable. Keeping with this goal, as company personnel have worked with their customers in recent years, they have noticed the log jams that seem to occur as parts head to the cleaning process. They decided to look for a solution. The company has been importing screw machines since 1992. With about 350 Euroturn machines in the field, it has a lot of ongoing customer interaction. The parts cleaning issues the customers faced were clear.

In the ‘90s, American manufacturers were mandated to phase out the use of evaporative solvents and quickly began implementing aqueous solutions instead. In the meantime, European companies continued with solvent-based cleaning solutions, and instead, focused on ways to handle it in a more environmentally friendly way. With Gosiger’s existing ties to Europe (the builder of Euroturn machines is located in Italy), the company began examining cleaning solutions there and forged a relationship with iFP, a manufacturer of industrial vacuum parts washers that make use of solvents and ultrasonics to clean even the most complex of parts with blind holes, cross holes, small holes and interior features.

A relationship between the companies is a good fit because iFP is small enough that Gosiger can have some say in ways to modify the machines to solve some of the problems that American customers face. iFP, which sprouted from a fairly large family-owned fabrication company in northeastern Italy, has been a stand-alone business for about 5 years. As Gosiger presented the company with ideas for customizing the equipment to better suit the U.S. market, they found the adjustments to be easily implemented. The fabricating background of iFP has been a definite asset.

In one example, Mark Walker, group vice president at Gosiger, explains that his company saw an advantage to having a modular-style changer to allow customers to use the baskets they already have in the shop for holding parts in the washer. “If you go into a screw machine shop, you’ll find hundreds of baskets already in use. In Europe, these baskets would be based on the standard Eurobasket. In the U.S., baskets come in all shapes and sizes, and it just didn’t make sense to force a shop to pour the parts from one basket to another for the washing process. Dealing with a fabricating company, we were able to make a simple adjustment to the chamber to allow for different basket sizes.”

The arrangement between the two companies has worked out well as Gosiger continues to spread the word about this non-aqueous method of cleaning. “There was a niche in the market that needed to be filled,” Mr. Walker says. “We’re doing some missionary work to inform people of the technology, but a lot of people are already aware. Many companies are at the stage where they need to move on from using solvent and dunk tanks. But there are a lot of people who have already made substantial investments into aqueous solutions and evaporators. So for them in particular, it’s the initial investment that becomes the biggest hurdle.”

Vacuum Solution

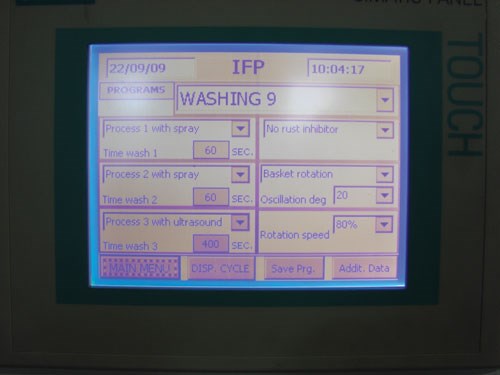

The operation of the vacuum system is relatively simple. The operator loads the basket with parts, puts it into the chamber and closes the chamber door. Alternately, an automation system can bring the basket of parts into the chamber. Once sealed, air is pulled out of the chamber to create a vacuum, and it is filled with solvent. The program assigned to the part specifies the amount of time the solvent will stay in the chamber and the action involved (rocking or rotating of the basket or ultrasonics). The solvent is then drained and another vacuum is created to pull out the residue; no air pockets or fluids remain to hold any particulate in. The process can run multiple times, depending on the application and the desired level of cleanliness. Also, as an option, a separate tank on the system can apply a rust preventive solution.

A careful study of the parts and their requirements determines the most appropriate process, but it will include some combination of washing, agitation, ultrasonic and rust preventive, with varying amounts of time applied to each. Mr. Walker explains, “There’s a dynamic to the cleaning process. You may want to use ultrasonics on every part if you want them all to be perfectly clean. But there’s a cycle-time penalty for that. On the other hand, the fastest cycle time might involve only a simple solvent soak, then vacuuming it out, but that’s the least effective cleaning. If that’s all that’s needed, great.”

Blind holes, small holes, cross holes, ID threads and other interior features will require the most thorough cleaning, but that’s where this system really earns its keep. And that’s where the tweaking needs to be done. But when the most effective process is determined for a given part, it is applied to the part number and stored through the PC-based front end. The next time that part is run, all that is required is the part number, and the system pulls the stored wash process from memory. These stored processes also provide a head start when programming new, but similar parts. Only minor adjustments may be needed to optimize the process for the new part.

Implementation

Automation of the system is fairly common. Basic components including a conveyor, an automated door on the chamber and a slide to move the baskets in and out are all that are needed. A barcode reader can be added to determine part numbers and to select the appropriate cleaning cycles based on stored programs.

The system, whether automated or not, can be set up in a couple of different ways. One option is to take advantage of the modularity of the changer and the different sizes of machines and include the machines as cell elements. Multiple units could be placed in various locations in the shop, allowing easy access and quick processing of parts. Another option, for shops that prefer to handle all chemicals in one central location on the shop floor, is to use a single unit that can handle all of the shop’s cleaning needs. In these cases, to allow more efficient movement of parts to and from the cleaning operation, a larger automation system such as a wire guided cart could be installed.

As with any investment, the key to the implementation of a vacuum parts washing system is that there should be a good business case for doing it. Obvious areas of consideration for how this system might reduce costs include fluid disposal for solvents or oily detergent water and the associated labor requirements to handle these processes. Another potential source of savings comes in power. Electric rates are different at different times of the day. Some of the vacuum system’s operations, such as distillation, can easily be performed at night when the power expense is less. If automation is added, even the cleaning can be performed during off-peak hours.

One cleaning-related cost that shops often overlook adds up during the sorting of parts that did not get cleaned well enough. With a highly effective parts cleaning system, this sorting process can often be eliminated. It is here that Gosiger sees an opportunity for an 18-month return on investment or better.

Conversely, the vacuum system may not be the best choice in cases where an aqueous solution is performing adequately and part volumes are extremely high. Pass through systems are particularly effective for such applications.

Remote Diagnostics

For easier fine-tuning of the cleaning processes and troubleshooting as necessary, the iFP system includes online monitoring tools to allow control of the system from remote locations. Gosiger takes advantage of these remote diagnostic capabilities to help customers transition smoothly to programming the system on their own. “When a customer gets a new machine, they have a lot to learn regarding different wash cycles,” Mr. Walker explains. “A number of different parameters can be set on the machine based on the part, how fragile the part is and how long it should be in each stage of the cleaning process. It’s sort of an art form in getting parts to their optimum settings.”

The online monitoring allows Gosiger to keep an eye on the customer’s processes without having to be there every day. The customer may call and say he needs a little better clean on a given part, and support personnel can see the settings and make adjustments as necessary. Close monitoring varies from shop to shop, depending on how quickly they grasp the machine and how to adjust the settings for changing applications. But this remote fine-tuning reduces later trouble shooting and gives the customer more confidence in tweaking the processes.

Process Equipment

It’s different than a machine tool. The parts washing equipment in a shop is mostly given little credit—it’s considered an added burden or expense necessary only to keep the customer happy. But Gosiger is on a mission to gain at least a little more respect for this process equipment. By monitoring the customer’s processes, the company can help ensure quick success (also known as cost savings and bigger profits). By working closely with the manufacturer, it can communicate customer needs and help to implement design modifications that address the trickiest of cleaning applications or maintenance requirements. As part of this effort, all of the replaceable parts of the machine purposely are readily available in the U.S. While maintaining the European engineering design, all switches, pumps and other parts have been replaced with parts that are in stock here in the States.

As shops examine ways to meet their customers’ cleaning requirements, a close look at vacuum technology may provide the answer.

RELATED CONTENT

-

VIDEO: Vapor Degreasing Process Uses TCE Replacement to Eliminate Hazardous Waste

A solid relationship with a solvent manufacturer has aided Electro-Spec Inc. with the implementation of a trichloroethylene replacement material in its vacuum degreasing unit to clean a customer’s micromachined parts more efficiently.

-

Cleanliness Compliance is Critical for Automotive Suppliers

Although not every shop has been affected by cleanliness specifications, many suppliers to automotive OEMs are already complying with stringent cleanliness standards. In Ford Motor Co.’s case, it has created its own cleanliness standards in order to save money and credibility.

-

Heat’s Impact on Parts Cleaning

Thermal dynamics is important for assisting in the cleaning of a part. Adding heat or energy influences the cleaning process through its impact on chemistry, the water within the washer and its effect on drying.