Re-Turning Adds Life to Train Wheels

Unique turning considerations and circumstances come into play when re-turning well-worn freight and metro rail wheels.

#workforcedevelopment

Unique turning considerations and circumstances come into play when re-turning well-worn freight and metro rail wheels. Specialty tooling geometries and grades are available to optimize any number of wear conditions. It’s a big business.

Re-turning, which essentially is a re-profiling operation, maximizes railway wheel life and serves to extend rail life as well. Wheels are less expensive and less labor intensive to replace than the rails, making railroad wheels the main consumable (next to fuel) in the rail industry.

Featured Content

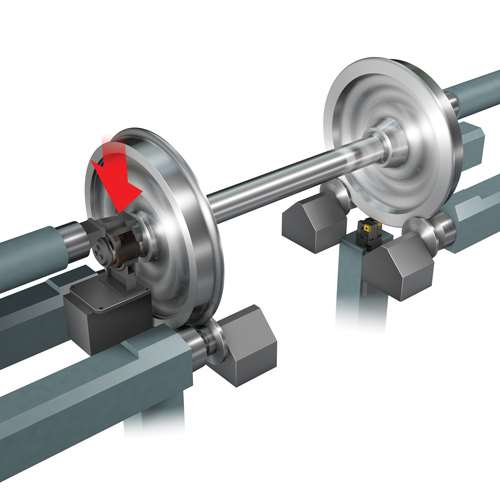

Throughout their working lives, railway wheel sets, which consist of two wheel disc units joined by a central axle, experience a constant weight stress from the load above, plus wear and tear from below as track conditions change. Two distinct machine styles are used depending on the wheel type, spanning wheels designed for commuter and subway trains, 70 ton or 100 ton freight car wheels, and more recently, high-speed wheel types.

Machining Styles

The more common, over-floor machine types tend to be portal machines with face drives. In this setup, the axle is fixed between centers on both sides, and the wheel set is driven by grippers, either on the ID or face. The tools profile the track-facing wheel surface starting on the distal surface, moving inward toward the center of the wheel set.

Freight car wheels, best characterized by their heavy wear and hard spots, make up the majority of wheel sets turned on over-floor machines, most of them being re-profiled. The high level of wear calls for a deep cut in order to repair the damage—usually this translates to a cutting depth (ap) of 0.200 inch to 0.300 inch (10 to 12 mm). This, in turn, requires an unusually high clamping force. Sandvik Coromant’s LNUX 32-style inserts are the most common types of carbide used in the United States and meet these demands, according to the company. Grades P25 are typically used with a style R1 chipbreaker.

Under-floor machines tend to be more commonly used when the wheel set sizes and shapes aren’t so standardized and easy to remove or swap from car to car. Heavy locomotives, high-speed trains and metro trains tend to use these under-floor machining setups.

On an under-floor machine, the trucks remain on the car. The car is rolled onto the machine from above, and the wheels are turned from underneath. During the operation, the wheel set is lifted up and driven by four conical rolls on the periphery. In order to create enough friction resistance to turn the wheel set while cutting, hydraulic rams are necessary. Sometimes, hydraulic cylinders loaded on the axle bearings have been used to assist the friction drive.

One downside to the friction drive has been the comparatively shallow depth of cut. A metro or high-speed wheel set may only achieve 0.080 inch to 0.125 inch (3 to 5 mm) in ap. Chip control is particularly important in under-floor machines, as gravity pulls chips into the operator areas. Proper chipbreakers are therefore a must in these operations.

Mobile under-floor machines can be transported to different locations by truck. Hegenscheidt, an under-floor machine supplier, offers a rental program for these machines. The machines are flexible; they are first fitted to the rails, then the trains are pushed into the workshop. Metro trains are lifted up by special platforms so technicians can work on the car’s underside.

Wheel Wear and Wheel Condition

Two areas that exhibit the most wear on wheel sets are the flange and the rim. The distance between the tip of the flange and the worn wheel profile, measured as h, generally is about 1 inch, but can be as high as 1.25 inch on badly worn wheels.

Wheel material hardness can also be affected by years of wear, particularly in areas where brakes are used frequently as in heavy-freight shipping. This can create RIM conditions as high as 45 Rc. Also, flat spots can occur on the track-contacting wheel rim, particularly if the wheels locked up or began sliding across the rail when braking. These flat spots are extremely hard and are difficult to machine. Thanks to new anti-lock braking systems, however, these issues aren’t as common as they once were. When dealing with hard spots, try to keep the insert nose below the hard spot.

Shelling is an undesirable side effect that occurs when already hard wheels are run too long. The hard spots chip out, creating a hole or crater in the wheel profile. These are particularly tough on inserts, and an operator needs to keep the insert nose below the bottom of the crater.

Sand, which is often used on railways to generate better traction in poor conditions and mountainous areas, can be another obstacle to re-turning. Individual grains of sand become embedded in the wheel itself, which in turn, creates heavy notch wear on the insert. When re-profiling a wheel set pocked with a lot of sand, it’s generally best to slow the speed down.

Stand-by and first choice: The universal carbide grade for railway re-turning is P15, which is recommended as the standard first choice for most conditions. Cutting speed is determined by the type of grade being worked with and the wheel condition. Still, John Winter, turning expert from Sandvik Coromant, recommends operators choose a lower cutting speed when turning hard wheels with brake plates and damage, and choosing a higher cutting speed with less worn wheels.

Advanced turning grade P25: Sandvik Coromant engineers are currently testing the P25 steel grade for applications in steel railway re-turning/re-profiling. The grade features technology that provides maximum tool life through a unique, unidirectional crystalline coating structure.

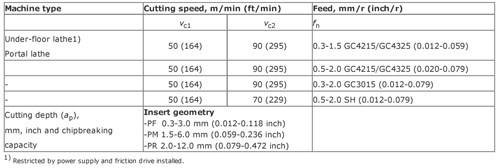

Cutting data: Chipbreaking performance is dependent on many factors, including material quality, cutting speed and entering angle. The cutting data table gives a general indication of how and where different geometries can be used. The cutting data is recommended for the type of material normally used in railway wheels.

When extreme skid flats, shelled tread or heavy buildup on the tread has occurred, the lower cutting speeds are recommended. Lower cutting speeds are also recommended when re-turning wheels with high carbon content. If any adjustment in the feed rate is necessary, it should be minimal.

The cutting speed recommendations (Vc1) in Table 1 are valid when turning tread of the wheel profile. The flange copying operation will normally be made with the higher cutting speeds (Vc2) and feeds given.

Tooling for Re-Turning

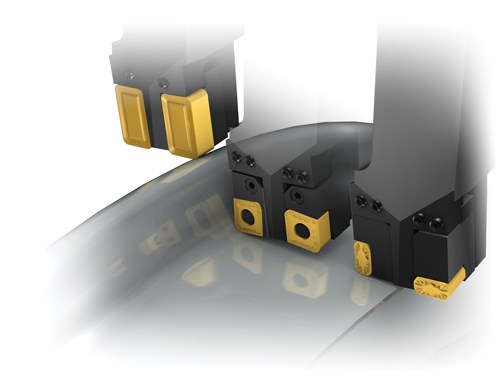

Tool systems for re-turning railway wheels include insert holders with replaceable seats for tangentially mounted inserts. This type of insert holds up to the immense stresses produced by large cutting depths at high temperatures.

When choosing tools and inserts, it’s important to bear in mind the type of wheel to be turned, the condition of the predominant part of the worn wheel, and the machine stability and its available power. It’s best to target as deep a cut as possible in order to achieve the shortest possible machining times. This isn’t always possible, however, because of previously mentioned wheel wear situations.

Still, in certain cases, profiles can be re-turned in a single pass. With other machines, it may be necessary to divide the machining into several stages in order to produce the right profile and the diameter wheel dimensions.

For most heavy freight wheels, inserts with high plastic-deformation resistance are needed for the heavy, deep cuts. Meanwhile, metro and high-speed rail turning tools require better chip control at smaller cutting depths. Sandvik’s CNMX with double-sided inserts for frequent returning is recommended for this application.

Insert assortments for all grades range from roughing, to medium to finishing grades in steel turning. Toolholder manufacturers such as Sandvik Coromant offer a range of specialized products to deliver the carbide to the wheel sets, including holders for “tandem” machines.

As a main consumable for this industry, railway wheels are not only less expensive to restore, but are also less labor intensive than restoring the rails, making it a cost effective and efficient choice.

This not only adds years of life to the railway wheels, but has the added advantage of extended rail life.

RELATED CONTENT

-

Making Micro Threads

Production of micro threads can be challenging, but using the most suitable tools for a given application can simplify the task.

-

Understanding CNC Collet Chucks

Workholding for turning is usually fairly basic: The selection comes down to chucks or collets. This article looks at when to consider the collet chuck and what kind might be best for a given application.

-

Tools and Technologies for Deep Hole Drilling

Understanding the challenges of deep hole drilling and knowing how to select and apply the appropriate tools will help a shop profit from this operation.