Software Meets Shop's Multitasking Machine Programming Needs

Structure Medical is not new to the medical supply industry; it is a spin-off of a company called Inovo, which is a manufacturer of oxygen regulators used in hospitals, nursing homes and the like. Inovo’s principals had been looking for growth opportunities.

In Production Machining’s August 2005 issue, we introduced Structure Medical Inc., a Naples, Florida, firm that specializes in the machining of bone screws and implants such as cervical plates for suppliers to the medical field. This company is not new to the medical supply industry; it is a spin-off of a company called Inovo, which is a manufacturer of oxygen regulators used in hospitals, nursing homes and the like.

Inovo’s principals had been looking for growth opportunities. Their research indicated that many of the firms in the business of machining surgical implants were using dated methods and equipment and that a company using newer, more efficient, less labor-intensive equipment to machine implants would have a significant competitive advantage in the marketplace. Accordingly, they launched Structure Medical in 2004, equipping it with the newest and most efficient multitasking machine tools they could find.

Featured Content

At Structure Medical, production consists primarily of two products that are used together by orthopedic surgeons to repair damaged bones. The first product is a relatively thin, contoured plate that supports and immobilizes broken bones while they heal. Plates are not a one-size-fits-all, multipurpose type of product. They are designed for specific areas of the skeleton; cervical plates (the company’s specialty) are used for neck injuries, wrist plates are used to fix shattered wrists and so on. They typically have multiple holes for screws that secure them to the bones. A representative sample of plates and bone screws machined by the shop is shown in the accompanying photo.

Plates are usually machined from titanium because of the metal’s combination of strength, light weight and relative inertness. The company typically machines its plates complete in one setup on one of the shop’s several, recently acquired Willemin W-408MT five-axis, bar-fed machining centers, supplied by Willemin-Macodel Inc. (Elmsford, New York). This machine is not a typical vertical or horizontal machining center. It is not designed to machine discrete workpieces, thus it has no provision for a worktable or workholding fixtures. Instead, it is designed to machine parts from barstock, which is typically fed into the machine spindle from a bar feeder. The compact machine’s size and shape are such that from a distance it could easily be mistaken for a CNC Swiss screw machine.

The machine’s spindle can rotate the bar at speeds up to 6,000 rpm for turning operations, and it can act as a C axis to index the bar for milling and hole-making operations. A single live tool spindle, capable of rotating speeds up to 30,000 rpm, handles the machining operations, moving in XYZ and swiveling up to 110 degrees in the B axis to present the tool to the bar. Serving the tool spindle is a tool magazine that accommodates 48 tools—rotary tools, turning tools or a combination of the two. Although Willemin refers to the W-408MT as a machining center, the term mill-turn machine more aptly conveys the the machine’s ability to go from milling to turning and back again quickly and easily.

Structure Medical’s second major product is the bone screws that pass through the holes in the plate and screw into the bone(s) to hold the plate in place while the bones heal. The bone screws are produced on a battery of five Traub TNL 12 turning centers able to accommodate bar diameters up to 0.62 inch and two (larger) Traub TNL 26 turning centers able to accommodate bar diameters up to 1.25 inches, all supplied by Index Corp. (Noblesville, Indiana). Production of the bone screws on the Traub machines using thread-whirling attachments was described in detail in the August 2005 issue (see "Learn More" at the end of this article).

In this article, however, we’re focusing on the software that the company selected to program its new multitasking machines. Many shops make sizable investments in multitasking machine tools and then discover that they can’t take full advantage of the machines’ capabilities because of the limitations of their existing programming software. These limitations force the shop to consider upgrading the programming software.

After reviewing the software available for its multitasking machines, the shop bought GibbsCAM MTM (Multi-Task Machining) programming software from Gibbs and Associates (Moorpark, California). Gibbs explains that GibbsCAM MTM addresses the programming needs of CNC multitasking and screw machine tools that employ multiple tool groups/turrets and multiple spindles that together provide more than four axes of motion. These machine tools, which are popular in Europe, are a growing market segment worldwide because of their highly efficient operation, which minimizes production costs in the areas of setup and part handling by performing all of the operations required to completely machine the part.

Gibbs notes, however, that widespread adoption of multitasking machines has been constrained because of the programming difficulties they present. GibbsCAM MTM addresses those difficulties by including a drag-and-drop graphical user interface that, the company says, makes programming multitasking machines easier. Synchronizing multiple aspects of a multitask process and transferring work-in-process pieces reportedly become straightforward operations thanks to a feature of the software called Sync Manager, which manages the various timing dependencies and presents the process flows to the user in an intuitive graphical view.

It Has A Post

GibbsCAM MTM supports numerous multitasking machine tool makes and models. In fact, one of the reasons that Structure Medical bought the software is that Gibbs had a post-processor for its Traub TNL 26 turn-mill machines.

Another reason is that Mike Rappach, who had recently been hired as senior engineer for Structure Medical, was familiar with GibbsCAM software, having used it to program Willemin machines in his previous position. Mr. Rappach recommended that the shop use the GibbsCAM software for the Willemin machining centers as well as for the Traub machines. Company management acted on the recommendation, spurred by Gibbs’ offer to provide a simultaneous five-axis post-processor developed specifically for its Willemin machines. Ironically, although the shop initially chose the GibbsCAM software for use on its turning centers, it first started using the software to generate simultaneous five-axis machining programs for its Willemin machining centers.

Although most of Mr. Rappach’s time is spent programming the Willemin machines, he is also responsible for programming the more recently added Traub TNL 26 machines. We asked what impresses him most about the GibbsCAM software.

"First of all, it’s fairly straightforward," he explains. "With other programming software, you have to go through a lot more commands and prompts to do what you want to do. With GibbsCAM MTM, you don’t have to wade through a lot of operations to get to the point where you can start creating tool paths. It is user friendly compared to other programming software I’ve worked with.

"The software is also able to handle the complexity of our machines," he continues. "Having several cutting tools in the works at the same time can dramatically reduce cycle times, but managing all of those moves can be intimidating. The software allows us to synchronize up to 16 axes at one time. We can create a program that takes full advantage of the capabilities of our machines without having to worry about things crashing into each other."

'Excellent’ Simulation Graphics

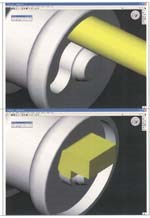

Mr. Rappach also likes Gibbs "excellent" machining simulation graphics that enable him to preview the machining operations on the monitor at the desk where he does his programming. The sequence of screen images below simulates the machining of a tiny titanium clip that is used to "lock" the heads of the bone screws to the plate after it has been installed. The T-shaped part measures 0.360 inch wing tip-to-wing tip and stands 0.135 inch tall if stood on its slotted, 0.071-inch-diameter center post.

These screen images simulate the machining of the part on one of the Willemin machines. (During our visit to Structure Medical, the clip was running on one of the shop’s larger Traub turning centers.) The first view (A) shows the front of the bar from which the part is machined. The bar OD has already been turned down behind its leading edge, and an end mill is shown milling a pocket with a round post in the middle. In the second view (B), a turning tool simultaneously shapes the post and slightly tapers the bottom of the pocket.

In the third frame, a saw blade has already cut a slot in the formed post. The spindle has indexed 90 degrees and the saw blade is shown cutting a second slot. The angles of the slots relative to the long axis of the part must be accurate within ± 0.5 degree.

In the fourth frame, the bar OD has been reduced further, and an end mill is shown starting to mill away the wall of the pocket to form the "wings" of the part. The fifth frame shows the part with all of the wall machined away except for the wings. A smaller end mill is shown blending corner radii where required. The last frame shows the completely formed part separated from the parent bar after cutoff (another turning operation). In a final step (not shown), the part is transferred to a backworking device for machining of the back end of the part. In this case, the operation is removal of the cutoff nib.

Mr. Rappach also likes the fact that the machining simulation can be tailored to show the actual configuration of a particular machine. "The representation can be very machine specific. The tool turrets, slides and other moving components can be made to appear in the simulation as they are located on the actual machine," he says.

Sales Surge Prompts Early Expansion

Where 2004 was a building year for Structure Medical, the company has been busy in 2005. It expects to double sales every year for the next several years. The company is already undergoing an expansion program in response to growing sales. It is adding an additional 10,000 square feet of manufacturing and office space by expanding into an adjacent facility.

The additional space will not only provide room for more production machines—including more Willemins and Traubs—but will also enable the company to make more efficient use of existing machines. Until now, the shop’s cramped 7000-square-foot facility has prevented it from adding bar feeds to more than two of its Willemins. On machines without bar feeds, spindle-length bars must be loaded in the machines one at a time, limiting the length of time that the machines can run untended.

The additional space will enable the company to equip more of its Willemins with bar feeds—all of the Traub turning centers are already equipped with these—enhancing the company’s ability to run jobs in a lights-out mode, which is important to its competitiveness. The company is a three-shift operation: a fully manned first shift, a lightly manned second shift and a night shift during which the machines operate almost entirely untended.

Kevin Confoy, general manager of Structure Medical, explains that the company pays attention to three areas in its efforts to stay competitive. "First, we spend a lot of time picking out what we feel are the best machine tools for the job—machine tools that make parts quickly and accurately and run without a lot of employee supervision.

"Second, we invest in good people who are capable of programming, setting up and running our production equipment," he continues. "Finally, we put a lot of time and effort into our setups. We want to make the part using the right tools for the job. It’s all about being able to let the job run largely or entirely untended. The biggest advantage that overseas competitors have is their lower labor costs. We feel we can be competitive by reducing our per-part labor costs. State-of-the-art machine tools are a part of the equation. A programming system that allows us to exploit the full productive potential of those machines is another. For us, the GibbsCAM software has proved to be that programming system."

It’s Already Helping

The GibbsCAM software is expected to play an important role in helping the company make maximum use of its expanded production capacity. However, the software is already making an important contribution to the company during the transition by helping it do more with existing equipment and personnel. "With the GibbsCAM software, we can program parts faster," Mr. Rappach explains. "That allows us to generate more programs to keep pace with a growing number of orders. It will also keep us from falling behind when we begin to take over our new space."

RELATED CONTENT

-

Keeping Watch on Small Parts

From watch parts to exotic medical applications, this shop takes on the world of micromachining.

-

Determine Equipment Effectiveness

Keeping the "green" lights on is the goal of overall equipment effectiveness (OEE).

-

VIDEOS: Tips for Screw Making on Swiss-Type Machines

Here’s a three-part video series focused on Swiss screw making to help explain the benefits of thread whirling, back turning and broaching while taking into consideration CAM programming, tooling and machine specifications.