They’re called “funny cars,” but the engineering effort that goes into these dragsters’ success is no laughing matter. Behind every winning car is a team consisting not just of drivers and support staff, but also programmers and machinists tasked with producing top-quality parts on sophisticated manufacturing equipment. The recent experience of one racing organization, Don Schumacher Racing (DSR), demonstrates the value of having a supplier that can help get the most out of this equipment. Thanks to tooling and support from Sandvik Coromant (Fair Lawn, New Jersey), the company has re-vamped a troublesome cylinder head manufacturing process to improve part quality and reduce setup time, cycle time and tool costs.

DSR was founded by businessman and former drag racer Don Schumacher, who started the operation in 1998 with a single Top Fuel dragster piloted by his son, Tony. The very next year, Tony won the championship, and DSR has since grown to seven full-time drag racing teams—four funny cars and three Top Fuel dragsters. To produce parts for these cars, the organization operates an in-house machine shop at its 120,000-square-foot headquarters in Brownsburg, Indiana.

The relationship with Sandvik began two years ago. To manufacture components on a larger scale, the shop had purchased nine Fadal CNC machines to supplement the two Okumas it already had. Along with those additions came a strong focus on process improvement. “We knew that Sandvik Coromant would provide the vital tooling and technology support we needed to get the most out of our CNC machining equipment,” says Mike Lewis, senior vice president at DSR.

Cylinder head production was among the first processes targeted for improvement. “The way these parts are engineered and machined can make a huge difference on the track,” says Alan Keep, business manager, northeast zone for Sandvik. “Accuracy and surface quality provide a competitive advantage.”

However, attaining requisite levels of either had proven difficult for DSR. Beginning with aluminum billet, the production process is both lengthy and complicated. “Machining involves a large number of tools and operations,” Mr. Keep says. “So when we started consulting and supplying tooling, we had to look at several aspects of the process.”

More specifically, machining often left blend lines on the cylinder head combustion surfaces. In addition, complex geometries and the requirement to drill 90 holes measuring 4.5 inches deep in each part caused quality and chip-clearance problems. Setup and cycle times were also too lengthy.

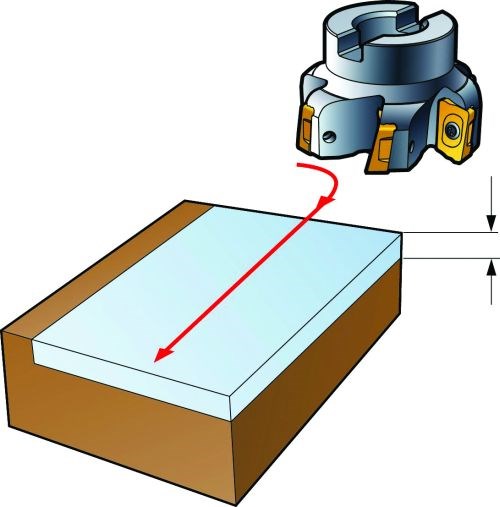

Initial analysis focused on face-milling operations. The 6-inch cutters DSR had been using for both rough and finish face milling had to be hand-loaded because they filled three positions in the tool magazine. Sandvik recommended swapping that tooling for a 4-inch CoroMill Century cutter that occupies only one position in the chain. This change reduced setup time and improved spindle utilization by completely eliminating the need for manual tool changes.

To eliminate the troublesome blend lines, the Sandvik team recommended a “roll-in/roll-out” motion in which the tool arcs into the cut in a clockwise direction. This simple programming technique reduces the occurrence of thick chips that cause surface-degrading vibration without sacrificing feed rate, Mr. Keep explains. As a result, surface quality improved by 58 percent, and machinists were able to increase speeds and feeds by 335 percent.

Next, the Sandvik team scrutinized profiling and drilling operations in an effort to combat quality and chip-clearance issues. The 1-inch, solid carbide end mill DRS had been using for profiling had a long

overhang that caused vibration problems, and the tool often had to be sent out for resharpening. The tooling supplier recommended swapping that cutter for a 50-mm-diameter Coromill 790 router. It also brought in a Coromant Capto C5 shank to boost rigidity. Finally, the team modified the CNC program to incorporate circular interpolation techniques that reduced radial and axial cutting depth while increasing sfm and ipm. Altogether, these changes reduced the load on the spindle, reduced vibration, improved tool life and simplified tool changes, which are now a matter of changing two inserts, Mr. Keep says.

For drilling operations, the team recommended swapping conventional, solid carbide twist drills for R840 CoroDrills. Unlike the previous drills, the R840s feature through-tool coolant capability. The resulting improvement in chip evacuation enabled the shop to eliminate time-consuming pecking cycles. The new tools also improved hole quality and reduced cycle time by 75 percent, Mr. Keep says.

Richard Price, DSR’s machine shop manager, says the wins Sandvik has helped provide in the shop have translated into wins on the track as well. A year after the two organizations first collaborated, DSR collected its ninth NHRA world championship when driver Matt Hagan powered his DieHard Advanced Gold Funny Car across the finish line in Pomona, California. In all, DSR won 18 races and three national records in 2011. “It’s a fantastic partnership,” Mr. Price says.

RELATED CONTENT

-

Choosing the right tools and matching them to the correct operations and process techniques for micromachining applications is critical to success in this burgeoning market.

-

Conventional honing has been continuously improved and automated, now allowing boring accuracies to be measured in millionths.

-

By grinding the entire workpiece contour in a single operation, the Grindstar can produce large batch sizes economically, making it an alternative to turning for the automotive industry.