In putting together this anthology, we discussed whether some of the stories might be slightly out of date. To that end, we only selected those stories that have currency.

For the most part, while turn-mill technology continues to evolve both in capability and application, the fundamentals of the technology remain. Our recommendation is that if one or more of these stories strike a chord, the reader should contact the vendor listed to find out more about its most current model or release.

It’s our purpose here to simply expose a new group of manufacturers to as much turn-mill technology, in the form of machines, processes, programming and applications, as possible in a single showing. By the way, the vault at productionmachining.com contains much more than these selections.

Let’s roll ’em.

Multitasking Technology for Turn-Mill Lathes Evolves

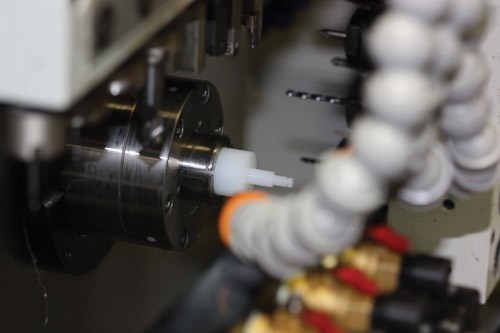

The concept of turn-mill on one machine has been around for quite a while. But the technology has evolved (and continues to) over time as OEMs have found new ways to optimize productivity, profitability and part quality.

This article begins with a short video clip of a turn-mill operation in action. The author then reviews the technological developments of turn-mill machines over time, from the early stages of adding backworking spindles to CNC lathes, or opposing twin spindles, to more recent machines with three turrets that include Y-axis capability. Each development was a move toward more complex part production while reducing cycle time and costs.

The article closes with a checklist to help a shop determine the right time to make a shift to multitasking production and to make sure it has the right tools in place. Learn more about the growing excitement of turn-mill capabilities at

short.productionmachining.com/TMEvolve.

When to Combine Milling and Turning

Released in May 2008, this article features an in-depth look at some of the process considerations surrounding the application of turn-mill technology. Technologically, the article uses a Mori Seiki turn-mill machine as an example of the flexibility of the multitasking capability to machine complex parts in a single handling.

As for the application of this technology, Pfeifer Industries in Naperville, Ill., tells how the installation of turn-mill machines has helped it compete by reducing multiple operations to a single handling. One example cited is a part that the company previously produced with 3 minutes, 15 seconds of turning and 4 minutes, 8 seconds of milling. The part was reduced to a total of 5 minutes, 20 seconds when run across the turn-mill center. Production was upped from 87 parts per day to 252 parts per day.

The article explains how faster part processing and reduced work-in-process allow shops to respond much faster to rush jobs. Since separate turning and milling operations rarely balance out in cycle time, eliminating the need to wait for one process to catch up to the other significantly improves throughput and reduces lead times. Read the full story at short.productionmachining.com/TMCombine.

CAM and Turn-Mill: Making More with Less

Often a stumbling block to investing in turn-mill technology is a perceived difficulty in programming the machines. How much to optimize the multiple operations in a sequence that is most efficient is the subject of this article.

It looks at how Norriseal, a Houston, Texas, based manufacturer, overcame this concern using sophisticated software, in this case

Edgecam from Planit Solutions, to confidently program its turn-mill machines. It also discusses how the company dealt with the human resources side of the equation by involving its personnel in the decision-making and implementation of new software and machines, providing the employees “buy-in” and helping ensure success.

It’s safe to say that software developers have come a long way in recent years to automate and simplify the programming of sophisticated, multitasking machines. Better posts and vastly improved simulation have virtually removed any hesitancy about the programmability of turn-mill machines. You can read the full story at

short.productionmachining.com/TMCAM.

A New Breed of Turn-Mill Center

Dropping parts complete in one chucking is the goal of most progressive precision machine shops. And there has been a steady parade of capable machine tools to help meet that goal. But in 2009,

Index introduced its R200 turn-mill center that features the main horizontal 65-mm spindle moving in Z (390 mm), the 65-mm subspindle moving in X (600 mm) and Z (390 mm), the milling spindle No. 1 (top) moving in XYB, and milling spindle No. 2 (bottom) moving in YB.

The result: a design with two, five-axis independent subsystems, exceptional stiffness and impressive dynamic response. According to the company’s engineers, the design of the R200 allows it to machine equivalent workpieces almost twice as fast as commercially available turn-mill centers that use only a motorized milling spindle.

Visit

short.productionmachining.com/TMNewBreed to read about how this machine tool can take precision part production a step further regarding the complexity of the parts it can process in a single operation while reducing the cost to produce those parts through quicker processing and reduced energy usage.

Turn-Mill Machines Turn a Shop’s Situation Around

This mini-feature tells the story of an engineer from TriContinent Scientific Inc. (Grass Valley, Calif.), who visited the MD&M show and took an hour to observe the Cyclone CNC turn-mill center from Ganesh in action. He could tell that the machine could be the solution to issues his shop was facing with a certain valve part that was to be used in a syringe pump.

The machine’s small footprint and sliding headstock initially caught the engineer’s attention, but the machine’s entire capabilities for producing the required geometries of the part, including the finish, were the deciding factors in making the purchase.

Being able to produce the part in-house has made the production process more manageable for this shop, cutting development time in half and saving about $3 per part on a run of 50,000. Get more details of what drove this shop to purchase two more Cyclones at

short.productionmachining.com/TMAround.

Boost Throughput with Multitasking

This double-feature begins with a look at increasing demands for reduced leadtimes and improved machining accuracy. For a shop that is looking for alternative opportunities to grow its business, turn-mill machines present an option to open additional markets that go beyond the typical screw machine niche. This technology can bring a shop into low- and medium-volume and prototyping work that otherwise may not have been practical.

Mazak’s Integrex line of multitasking machines is designed to reduce manufacturing costs by cutting handling and setup time, reducing the number of fixtures and tools and shortening waiting time. A single machine allows a shop to be competitive on round parts with secondary operations, fully prismatic parts from solid or casting or sculptured parts such as aerospace components and molds.

The second act reviews programming considerations for multi-axis lathes. Hanan Fishman, from PartMaker, provides his views on what it takes for a CAD/CAM system to handle the complex operations of these machines.

CAM Package Unlocks Turn-Mill Capabilities

By performing turning, drilling, milling and other operations in a single platform, multi-spindle turn-mill machines enable users to cut parts complete without requiring additional setups. However, taking full advantage of these machines’ capabilities can be difficult without CAM software that can handle simultaneous operation of multiple spindles.

One cutting tool manufacturer solved this problem by implementing Delcam’s FeatureCAM software package. In addition to the ability to synchronize spindles during off-machine programming, the software offers machine simulation and feature recognition capabilities that have further improved productivity.

Spindle synchronization eliminated manual cut-and-paste adjustments on the shop floor and reduced total programming time from hours to minutes. The software also provided the company with further opportunities to improve productivity, including boosting the number of tools available to machine a part.

You Have the Combination

These trailers are only a small example of what can be found in the Production Machining vaults. Our archives contain material from 10 years of publishing about the precision machined parts industry. Turn-mill is only one topic.

Moreover, we don’t have a lock on the vault. It’s open to anyone looking for relevant content about precision machining. You have the combination. It’s productionmachining.com, and with it you can find and explore information about pretty much anything germane to your business. Come in and wander around.

RELATED CONTENT

-

Growing economic and labor pressures are making CNC multi-spindle turn/mill technology more viable than ever. This real-world comparison to a single-spindle lathe shows how.

-

A shop in Big Sky Country uses a B-axis multitasking machine to produce complex, prismatic medical parts that require no turning complete from barstock.

-

Working closely with its machine tool supplier, this firearms manufacturer has quickly expanded its lineup of turning machines to deliver quality products and faster delivery.