Ultrasonic Cleaning for Large Lots of Small Parts

Machining operations such as turning, milling, drilling and grinding leave traces of contaminants behind on workpieces. Ultrasonic cleaning allows for the removal of coolant, chips, polishing paste and other residue in a quick, reliable and economical manner.

During machining, surface contamination of the workpiece is inevitable. But soils such as residue of cutting fluids, swarf, friction and polishing paste usually cause problems in upstream processes or may affect function, quality and lifespan of finished products. That’s why machined parts need to be cleaned. Unfortunately, parts cleaning often becomes a bottleneck in the production process, particularly for large lots of parts produced in chip-forming operations. With ultrasonic cleaning, particulate and film-like soils can be removed not only reliably, but also very quickly and efficiently—even for parts with difficult to access, hollow spaces such as blind holes, knurling and grooves.

Cleaning Effect of Sound Waves

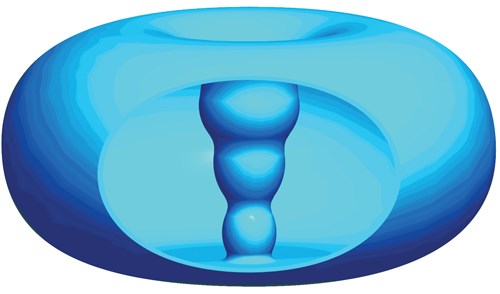

Ultrasonic waves develop their cleaning effectiveness in a liquid bath. The process is based on the physical cavitation effect: When a liquid is subjected to ultrasonic waves, the high intensity of the alternating sound pressure during the pulling phase of the oscillation cycle breaks up the liquid and the cohesive forces are overcome. This process causes the formation of millions of microscopically small bubbles. During the subsequent pushing phase, these cavitation bubbles are rendered unstable and collapse (implode). They generate hydraulic impacts with considerably high energy densities, thus causing micro-currents in the liquid. When these micro-currents strike a surface, they blast off contamination that has been partially dissolved with a suitable cleaning agent. The “dirt” is rinsed away.

Featured Content

A Decisive Criterion

The sound waves are produced by a generator that converts the normal electrical frequency of 50 to 60 Hz into high-frequency oscillation. Sonic transducers then transform this electromagnetic oscillation into mechanical oscillation of the same frequency. The ultrasonic frequency has a significant influence on cleaning results. Generally, the lower the frequency, the larger the cavitation bubbles and, thus, the more energy they release. Standard frequency ranges have been established for optimum cleaning of different types of machined parts:

- 25 to 35 kHz - Removal of particles, grease, oil and other contamination from hard, unpolished surfaces such as engines

- 40 to 80 kHz - Final cleaning tasks and cleaning of porous and polished surfaces

- 120 kHz and above - Micro-cleaning tasks and cleaning of finely porous and high-gloss, polished surfaces

Multi-frequency or mixed-frequency ultrasonic systems can be used for certain components, particularly those with highly complex shapes, to address the varied cleaning needs. The mixed numbers of larger and smaller cavitation bubbles achieve ideal cleaning forces for both outsides surfaces and boundary surfaces.

Matched to the Cleaning Task

In addition to frequency, other factors such as power, placement and quantity of transducers will play a critical role in the performance of an ultrasonic cleaning system. As a rule, good cleaning results can be achieved with a power rating of 8 to 10 watts per liter. A typical cleaning bath of 100 L requires 800 to 1,000 watts of power.

Because the sound waves are propagated longitudinally from the sound emitting surface, the arrangement of the transducers has a considerable influence on cleaning results as well. If the transducers are only attached to the floor of the working chamber or cleaning basin, the sound waves are emitted vertically up to the surface of the bath, and then reflected back down to the floor. This flow has consequences for the cleaning of parts with hollow spaces and blind holes: If bubbles form in these areas, the air creates an obstacle for the sound waves, preventing cleaning action. For this reason, all hollow spaces must be filled with cleaning fluid by oscillating or rotating the parts within the bath. As component shapes become more and more complex, ultrasonic cleaning systems are being equipped with oscillators at multiple locations, such as on the floor and the side walls.

Applicable with All Cleaning Agents

Ultrasonic cleaning falls into the category of wet chemical cleaning techniques and is applicable with aqueous cleaning agents as well as solvents. For the selection of an appropriate cleaning agent, the maxim “like dissolves like” (similia similibus solvuntur) applies. If the chipping process is carried out with a non-polar cutting fluid such as mineral oil or grease, a solvent is usually the right choice. Chips and particles, which are polar contaminations, forfeit their adhesion to the workpiece surface through the removal of the oil or grease and will be carried away by the ultrasonic cleaning effect.

Polar substances such as aqueous coolants, polishing pastes, chips, friction, and salt, dissolve in aqueous cleaning agents (polar media). These media are available as pH-neutral, alkaline and acidic cleaning agents. Usually the compatibility of the material to be cleaned and the achievement of required cleaning results are adjusted by cleaning tests conducted in the test facilities of the system or cleaning agent manufacturer. To provide for stable cleaning results, aqueous cleaning processes require frequent process monitoring. Process parameters such as concentration of detergent, temperature, ultrasonic power, rinsing water quality and filter runtime should be checked.

As an additional option, polar solvents and modified alcohols combine the advantages of aqueous cleaning agents and solvents.

By using ultrasound in combination with a cleaning agent that is matched to the respective type of contamination, cleaning time can be reduced by as much as 90 percent. At the same time, cleaning agent consumption can also be reduced. Conversely, the wrong cleaning agent influences process stability and cleaning results in a negative way. If very oily parts are cleaned by an aqueous cleaning process, for example, bath lifespan drops off significantly, the required cleanliness will often not be achieved, and process costs will increase.

System Concepts

Ultrasonic cleaning is mostly used in single-chamber and multi-tank dipping systems. Single-chamber cleaning systems are equipped with a closed working chamber and one or more tanks for fluids. The parts to be cleaned are fed into the chamber in baskets as bulk goods or in workpiece carriers. The working chamber is then successively flooded with the cleaning and rinsing fluid and, where necessary, with preservation or passivating agents. Ultrasonics can be used as needed during all steps. In the ideal scenario, the medium will be filtered in a bypass line during filling and draining and throughout the cleaning cycle itself. Drying is likewise carried out in the chamber. If solvents are used as the cleaning agent, the ultrasonic cleaning process takes place in fully closed, single-chamber cleaning systems with integrated distillation units for reconditioning of the solvent. These systems allow for recirculation of the used solvents.

Multi-tank dipping systems are used only in combination with aqueous cleaning agents. These open systems allow for any number of treatment modules to be arranged in a series. Because this arrangement offers a high diluting effect, fine cleaning is one typical field of application. Another advantage is the high throughput capacity, given that several batches can be treated in the different baths simultaneously. The parts to be cleaned are delivered to the various immersion baths using trolleys or vertical step conveyors.

Optimal Cleaning Tank

The product carrier also has a significant influence on the cleaning result and duration. Whether the parts are cleaned in bulk or staged, cleaning baskets made of stainless steel round wire are recommended for ultrasonic cleaning. They allow access to the parts for the ultrasonic waves and cleaning media.

Overly dense loading of the bath (parts stacked closely on top of each other) or large volumes of bulk goods prevent the ultrasonic waves from reaching all of the workpiece surfaces to be cleaned. As a rule of thumb, the surfaces to be exposed to ultrasonic waves should not be bigger than the sound emitting surface. At the same time, the mass of the part or parts should not exceed 50 percent of the volume of the bath.

RELATED CONTENT

-

Cleanliness Compliance is Critical for Automotive Suppliers

Although not every shop has been affected by cleanliness specifications, many suppliers to automotive OEMs are already complying with stringent cleanliness standards. In Ford Motor Co.’s case, it has created its own cleanliness standards in order to save money and credibility.

-

Cleaning Parts Cost Effectively

A shop should look at all aspects of the production process to maximize productivity. This includes selecting an efficient cleaning system.

-

What Does 2021 Have in Store for the Parts Cleaning Industry?

With a new opportunity to do good things in your organizations this year, I hope you use the parts cleaning section and this year’s and last year’s Parts Cleaning Conference as tools to succeed.