MC Machinery Systems Inc.:The Company Behind Mitsubishi EDM

The company is responsible for selling and servicing the popular EDM machines with the Mitsubishi EDM brand, but it also sells and services many other types of advanced machining solutions, such as vertical machining centers, automation, advanced five axis milling, turning, additive machining, CO2 and FIBER Laser, and hydraulic and electric press brakes.

Many people do not realize that MC Machinery Systems Inc. is the company behind the Mitsubishi EDM brand.

Most people are familiar with the Mitsubishi EDM brand. But many do not realize that MC Machinery Systems Inc. is the company behind the brand. In fact, MC Machinery Systems is celebrating its 25th anniversary as a U.S. subsidiary of Mitsubishi Corporation this year.

The company is responsible for selling and servicing the popular EDM machines with the Mitsubishi EDM brand, but it also sells and services many other types of advanced machining solutions, such as vertical machining centers, automation, advanced five axis milling, turning ,additive machining, CO2 and FIBER Laser, and hydraulic and electric press brakes.

“We want people to know that we sell advanced technology. We are a solutions provider, our product range is vast, and we can really work with customers on finding the tool that best fits their manufacturing needs,” says Patrick Simon, marketing manager, MC Machinery Systems.

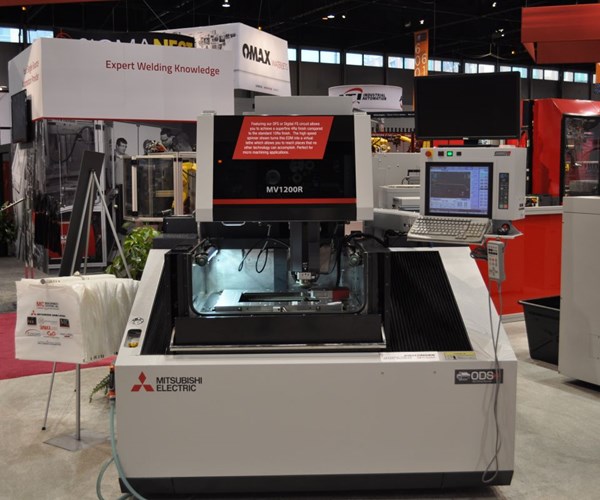

The proof is in the booth. While visiting MC Machinery’s 10,000 square-foot booth (Booth N-6815), visitors can experience 15 of the company’s machines on display. Six of these machines feature automation. In addition to its EDM machine line up, one example of the company’s machines featured at the show is the five-axis OPS Ingersoll Eagle V5 with multi-change light automation. This VMC has the capacity to handle a 550-pound workpiece on a 15.75-inch table surface.

The company’s new Remote 360 monitoring system is also featured in the booth. “MC Machinery can now access customers’ machines with their permission, through Remote 360, a machine monitoring system that began coming standard on all wire EDM machines April 1,” Simon explains. “We are demonstrating this on several 70-inch flat screen TV displays, with presentations throughout the week. This capability allows us to reach a higher level of customer satisfaction and reduce downtime.”

MC Machinery’s top, high level employees are in the booth all week to answer questions, meet new customers and give machine presentations. It’s a great opportunity to meet with experts in each area of the company.

“There are several consumable products available for customers who have purchased our equipment, along with after sales contracts, like preventive maintenance programs and extended warranties,” Simon says. “We also plan to do some giveaways associated with our 25th anniversary.”

While looking for the Mitsubishi EDM logo, keep your eyes open for the MC Machinery 25th anniversary logo, and prepare yourself to be pleasantly surprised by all this company offers when exploring the booth.

RELATED CONTENT

-

Smart Workholding Device Measures and Monitors

Sensor and IIoT technology combine to enable these chucks and mandrels to automatically monitor workholding parameters and measure part features to ensure process stability.

-

What Is The Best Bar Feed System For Production Turning?

Selecting the right bar feeder can be one of the most important decisions a shop can make. Bar feed systems help improve productivity, throughput and quality, but in order to achieve the most benefit from them it is essential that a bar feed system be matched to the particular needs of the turning operation.

-

Job Shop Automation: Fast, Simple and Agile

When done right, automation can provide important benefits. Here’s a look at automation options to suit the varying needs of typical job shops.