Thinbit IMTS Booth Offers Hands-On Experience

Visitors to the booth can use touchscreen displays and watch videos to learn more about this company’s tooling products. They can also discuss projects with application engineers in the booth.

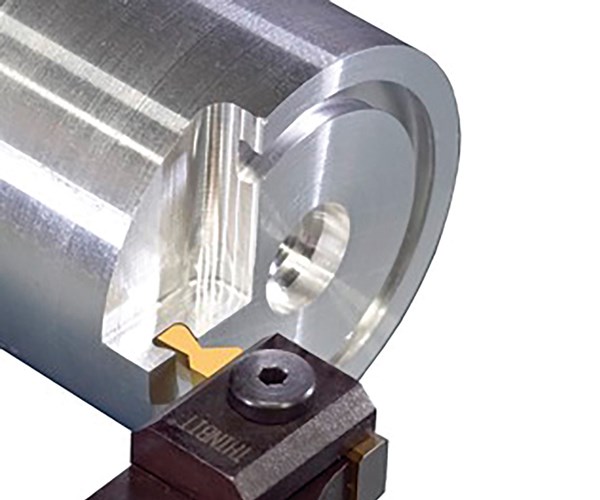

The company’s Groove ‘N Turn line of dovetail grooving inserts are one of many cutting tool lines featured in the booth.

To see a full line of inserts and tools for grooving, threading, boring, face grooving, parting and form tools, visit Thinbit/Kaiser Tool Company’s booth W-2172 at IMTS. Visitors to the booth can use touchscreen displays and watch videos to learn more about this company’s tooling products. They can also discuss projects with application engineers in the booth.

The company’s Groove ‘N Turn line of dovetail grooving inserts are one of many cutting tool lines featured in the booth. The insert design is optimized for strength by using an insert pair to generate the groove form. Insert sizes are 0.030”, 0.050”, 0.060”, 0.070”, 0.080”, 0.090”, 0.100”, 0.125” and 0.150” with major diameters starting at 0.300”. These inserts are also available in sub-micron grain carbide grades for ferrous and non-ferrous materials, either uncoated or with TiN, TiCN, TiAlN or diamond film coatings. These dovetail inserts can be used on conventional, Swiss and CNC machines.

Thinbit/Kaiser Tool Company engineers in the booth are eager to answer questions and discuss options available to help with production and solve problems that attendees might be having with lathe applications. They want to help shops cut expenses and improve production.

Stop by the booth for giveaways throughout the week. If you are a Thinbit customer already, you can enter a contest to see if you have the oldest Thinbit scale.