Three Hands Beat Two

Co-bots are a technical leap forward from the traditional industrial robot that has evolved from its introduction in the 1950s.

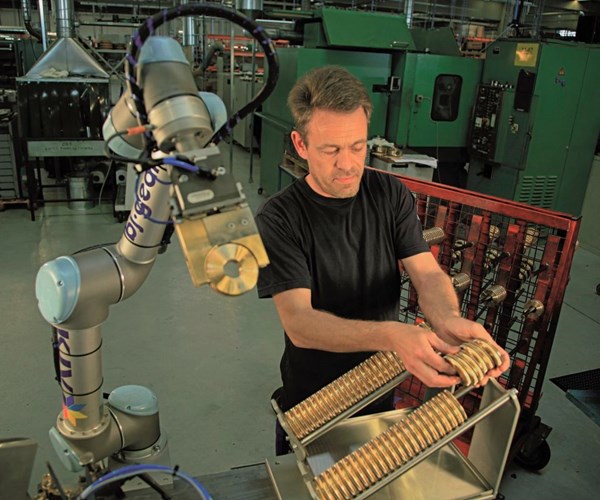

When you need an extra hand.

Three hands beat two hands is the theme of an article we published last year on application of collaborative robots (co-bots), called "Collaborative Robots for DIY Automation." At the recently completed IMTS 2016, these safety conscious helpers were part of an automation feeding frenzy that helped draw the third largest attendance in the show’s history.

Since we published this piece, co-bots have taken off in dissemination within manufacturing and proving their worth across most every industry spectrum. Co-bots are a technical leap forward from the traditional industrial robot that has evolved from its introduction in the 1950s.

With co-bots, the walls of solitary confinement required to keep machine and man at a safe distance have come down. Hyper sensor technology on these machines make human and co-bot interaction perfectly compatible and safe even in close proximity.

Now when a worker needs “an extra hand,” it’s sitting right next door.

RELATED CONTENT

-

Smart Workholding Device Measures and Monitors

Sensor and IIoT technology combine to enable these chucks and mandrels to automatically monitor workholding parameters and measure part features to ensure process stability.

-

Simplifying Machine Load/Unload Automation

Today, lower part volumes and frequent change-over are changing the offerings of some automation integrators. Standard, off-the-shelf components are being engineered to work together in a large variety of applications and, in some cases, are even portable so they can be moved from machine tool to machine tool.

-

Advantages of Cellular Manufacturing

Manufacturing cells are used to minimize product movement as well as materials, equipment and labor during the manufacturing process. By reducing cycle times and material handling, these cells help shops more easily meet customer demands regarding cost, quality and leadtimes.