Robotic Cell Cuts Cycle Time, Improves Part Quality

Sew-Eurodrive Inc. worked with Okuma America’s authorized systems dealer to design an automated cell that includes an automatic magazine bar feeder that loads 6-ft. lengths of barstock into the machine. The shop also switched to an Okuma twin spindle, twin turret turning center so all of the machining operations are completed in one setup.

Edited by Lori Beckman

Automation is not something every shop has experimented with, but shops who have often share great success stories. Sew-Eurodrive has a success story that starts with the shop reaching out to Okuma integrator Gosiger Automation for help producing a part more efficiently. The resultant system reduces cycle times and requires much less operator involvement. Production time per part has been more than cut in half—from about 5 minutes to 2 minutes, 20 seconds.

Sew-Eurodrive is no stranger to automation: It has almost 100 industrial robots that help automate production of component parts. Therefore, it was no surprise when the company’s Mechanical Engineering Technician Keith Waller turned to robotic automation to produce a new series of small-diameter pinions.

Featured Content

The U.S. headquarters of Sew-Eurodrive in Lyman, South Carolina, is a 250,000-square-foot facility that produces more than 300,000 gearsets and gearboxes each year. The facility is the sole manufacturer of these products that are used worldwide in conveyors, cranes, water treatment plants, roller coasters and myriad other applications.

“We process most of our pinions from blanks using face drivers, but we recently began producing a new series of pinions with diameters as small as 3 mm, which makes it virtually impossible to use a face driver,” Mr. Waller says. “Instead, we end-milled and center-drilled the workpieces, put them on a lathe for turning between centers and then milled a keyway. This process wasn’t very efficient, so we looked for a better approach.”

Mr. Waller invited four companies to propose a turnkey, robotically automated cell that would reduce production time, operator involvement and, because the company runs 45 different pinions through the system, eliminate lengthy change-overs.

Sew-Eurodrive awarded the project to local Okuma dealer, Morris South, working with Okuma America’s authorized systems integrator, Gosiger Automation.

While developing the new automated cell, Morris South and Gosiger Automation worked with Sew-Eurodrive to rethink the entire process, from raw material to finished parts. Previously, the pinions were machined from precut blanks delivered by an outside supplier. The new system relies on an automatic magazine bar feeder that loads 6-foot lengths of barstock into the machine. This change alone saves material costs while enabling unattended operation.

Switching to an Okuma LT-2000EX twin spindle, twin turret turning center means all of the machining operations are completed in one setup, thus eliminating additional fixtures and operator intervention. A floor-mounted, FANUC six-axis, M-710iC/50 industrial robot equipped with iRVision and two end-of-arm tooling (EOAT) grippers automate unloading the finished parts and servicing a coordinate measuring machine (CMM) that is integrated into the system for quality control.

The cell works this way: The bar feeder loads 1 inch to 2 3/8 inches in diameter, 8620 bearing quality steel barstock into the turning center. First, the turning center machines the backside of the head and the pinion shaft and mills the keyway. Next, the subspindle grabs the turned shaft where the front head dimensions are finished and center drilled.

Following the machining operations, the robot unloads the part and places it into the CMM to measure three diameters and the keyway width. The CMM sends these data to the machine tool to automatically make adjustments using software. Following inspection, the robot removes the part from the CMM and takes it to a dot-peen marking station where the part number is added.

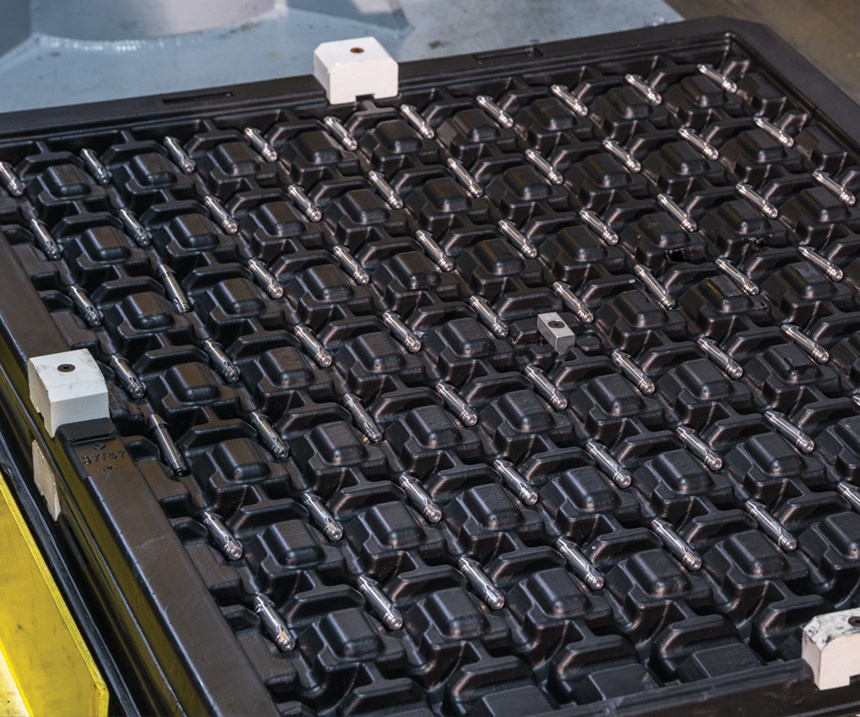

Using iRVision equipped with infrared light, the robot places the completed part into an outgoing tray. Once the tray is filled with completed parts, the robot takes an empty tray from an adjacent stack, placing it on top of the full tray. When the outgoing tray stack reaches its prescribed height, the system alerts the operator to remove the finished stack of parts and bring in another stack of empty trays.

In addition to reducing both production and operator time, the new cell provides an unexpected, but welcomed, benefit. “We were having some problems controlling runout during the turning process,” Mr. Waller says. “Once the pinions leave the work cell, they go to a gear cutting operation where they are clamped by collets on the ODs for teeth cutting. Then, they go to the grinding operation to make the journals. These operations won’t be accurate if we haven’t held the runout during turning to less than 20 microns. In the past, we had a hard time achieving that tolerance, and the operator spent a lot of time fighting runout. The automated cell routinely holds runout to between 6 to 10 microns, which has cut the operator’s involvement by 50 percent.”

The company operates the automated cell three shifts per day, five days each week, running lots of pinions—8,000 to 10,000. “Our operators are extremely happy with the cell and with how easy it was to learn and to run it,” Mr. Waller says. “We’ve worked with a lot of automation companies, and Gosiger Automation ranks right up there as one of the best, with the entire process of design, build and installation going smoothly.”

By putting its trust in Gosiger Automation, Sew-Eurodrive ended up with a more efficient process, using less manpower and less time, which also cuts costs.

For more information from Sew-Eurodrive Inc., call 864-439-7537 or visit seweurodrive.com.

RELATED CONTENT

-

Laser Technology "Turns" into a Turning Tool

This new technology uses a laser to act as a cutting tool to "turn" parts from solid barstock. This high-speed precision turning machine is especially useful for micromachining, enabling high accuracy for small, complex parts that are often delicate and difficult to machine when implementing conventional turning processes.

-

Understanding CNC Collet Chucks

Workholding for turning is usually fairly basic: The selection comes down to chucks or collets. This article looks at when to consider the collet chuck and what kind might be best for a given application.

-

A New Approach to CNC Turning

This turning process takes advantage of a turn-mill’s B-axis spindle to vary a tool’s approach angle to optimize chip control and feed rates.