Bardons & Oliver, Inc.

5800 Harper Road

Solon, OH 44139 US

bardonsoliver.com

440-498-5800 information@bardonsoliver.com

AS SEEN IN PRODUCTION MACHINING

Do you have a new product or news release that should be included here for Bardons & Oliver, Inc.? We'd love to include it! Send your content to our editorial team.

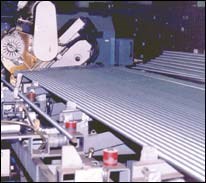

Bar Processor Boosts Blank-Making Capabilities

This toll processor of steel bar is hustling to meet the growing demand for 'first operation' blanks.

Product categories offered by Bardons & Oliver, Inc.:

-

Cutting Tools

-

Chamfering Tools

-

-

Finishing Equipment

-

Deburring Machines

-

-

Machining Cells & Systems

-

Material Removal Automation

-

-

Services

-

Retrofitting, Rebuilding, Remanufacturing Services

-

-

Special Purpose Equipment

-

End Finishing Equipment, Bar and Tube

-

-

Threading Machines

-

Pipe & Bar Threading & Cut-Off Machines -

Thread Cutting

-

-

Turning Machines & Lathes

-

CNC Turn/Mill Machines -

Cut-off Lathes -

End Turning Machines

-

-

Turning Machines & Lathes

-

Horizontal CNC Turning -

Twin-Spindle/Twin-Turret Turning

-

-

Work Handling

-

Bar Feed Mechanisms

-

Trade Names offered by Bardons & Oliver, Inc.

- Rotating Head Cutoff Machines

Is this Your Listing?

Connect with us to keep your company's information up to date.

.png;maxWidth=300;quality=90)