Mazak Syncrex Swiss-Style for Flexible, Versatile Operations

IMTS 2022: The series comes in four bar capacities, ranging from 20 to 38 mm, and is available in 7-, 8- and 9-axis configurations as well as a 9-axis model with full B-axis contouring.

How Advancements in CNC Multi-Spindles Can Put You Ahead of Current Trends

Growing economic and labor pressures are making CNC multi-spindle turn/mill technology more viable than ever. This real-world comparison to a single-spindle lathe shows how.

The Right (Machine) Tool for the Right Job

This high-production shop uses both mechanical and CNC Swiss machines to make parts, but which machine is right for which job?

#workforcedevelopment

VersaBuilt Lathe Automation System for High-Mix Production

The system includes the VersaBuilt System Controller (VSC) software which has all robot motion preprogrammed, thereby enabling deployment in hours rather than weeks.

#Industry40

5 Tips for Multichannel Programming

Programming for multitasking machines can be complex. Knowing several key points for making the process less challenging can save a programmer time as well as lessen confusion and the risk of error.

#basics #techbrief

Inside an Amish-Owned Family Machine Shop

Modern Machine Shop, PM’s sister brand, took an exclusive behind-the-scenes tour of an Amish-owned machine shop, where advanced machining technologies work alongside old-world traditions.

Index Corp.’s Sliding Headstock CNC Lathe for Small Parts Machining

The frontworking attachment and counterspindle are now housed on separate slides, which is said to eliminate potential interdependence between front-end and counter-spindle machining, enabling greater programming flexibility.

#horizontal-and-vertical-lathes

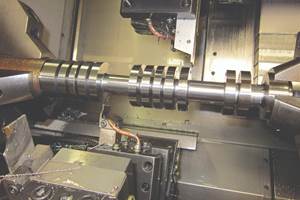

Shop Optimizes its Swiss-Turning Flexibility

Paramount Machine uses various Swiss-type lathes, some with a B axis, to produce parts more effectively than it did on conventional chucker lathes. Today, nearly every job under 1.5 inches in diameter runs across those machines even if the batch size is a mere 5 pieces.

Starrag’s Bumotec 191 Neo Turn-Mill Reduces Tool Change Time

The company says the 191 Neo turn-mill can also be used for grinding, polishing, skiving, gear hobbing and diamond cutting with no setup or fixture changes.

Automated Multitasking Machine Drops Parts Complete

This automated multitasking machine with an integrated robot eliminates the need to run parts across multiple machines, saving floor space, setup time and manpower.

#techbrief