As anyone involved in metalworking manufacturing is acutely aware, the battle between dedicated machining technology and flexible machining technology continues to be waged in machine shops around the world. The influx of high-mix and low volumes into metalworking manufacturing is unmistakable and, more than likely, unstoppable. It seems to permeate all aspects of machining operations.

These general terms—high-mix, lower-volumes—are relative. To a mold shop for example a lot quantity of five might be considered “high-volume.” In a tier two supplier high volume might be considered 500,000 pieces or more. And relatively speaking, the Tier-Two supplier with 500,000 pieces may have adjusted its production from a previous 1,000,000 pieces based on the overall manufacturing trends of the past few decades. Today, that same “high-volume” might be more like 5,000 pieces. It’s relative.

Featured Content

In the search for capital equipment that allows a shop to optimize its production to reflect the realities of today’s manufacturing demands, there are many machine tool configurations from which to choose. One of those designs we are featuring here. It’s called the multicenter and has been developed to be a bridge of sorts between high-mix, flexible production and high volume, dedicated machining capability.

Morphing Rotary Transfer

To find out more about the concept behind the Multicenter, we talked with Maurizio Porta, second generation owner of Porta Solutions, based in Brescia, Italy. Its North American headquarters is in Newington, Connecticut. Founded in 1958 by his father, Oscar, Mr. Porta’s company started building specialty machine tools for various applications and has seen the changes in dedicated versus flexible production requirements.

“Originally, we manufactured rotary transfer machine tools,” Mr. Porta says. “These machines reflected a time when a machine was built to manufacture a part. The part was king, and creating dedicated tools designed to optimize its production was the name of the game.”

Traditionally in rotary transfer technology, a shop would get a job and then design a production system around the part. Some jobs might run virtually unchanged for years. As product life cycles have become shortened, dedicated production machines have become less cost justifiable in many applications, primarily because re-tooling them for a new job is difficult, expensive and usually simply not worth the effort.

In 2005, Porta introduced its solution to the dedicated machine versus a flexible machine in the form of the Multicenter. The thinking was to bridge the dedicated machining technology designed around a specific part with a machining center platform that could easily be retooled as part mixes changed.

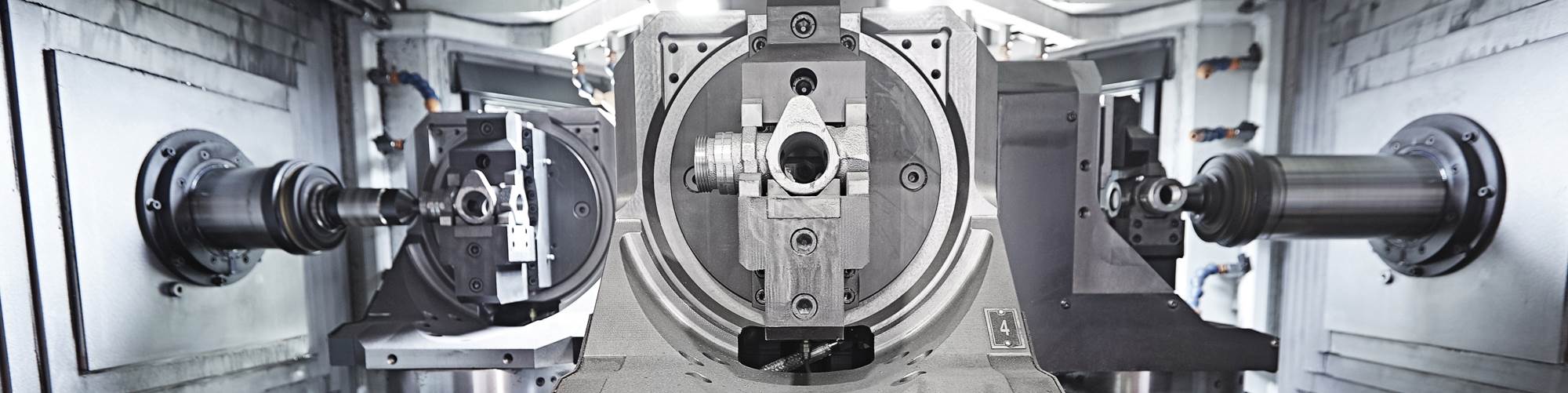

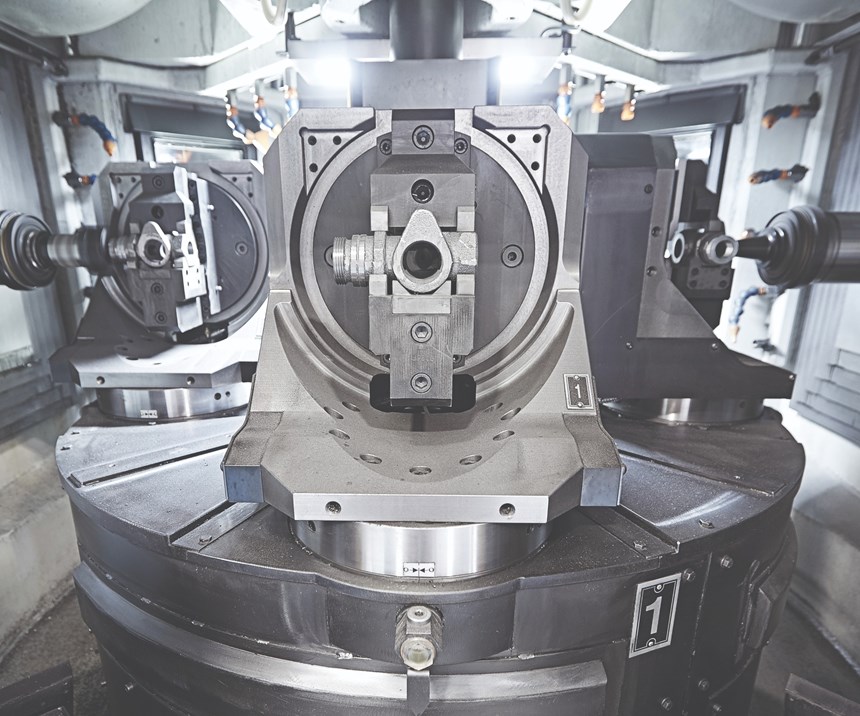

Centered on a four-station carousel, the machine, in its most popular configuration, features three horizontal machining center modules. The fourth station on the worktable is a load/unload station that can be manned or automated.

Each of the HMC modules is capable of three or true four-axis machining at each station. The machining center modules operate progressively, but are controlled independently. With the machine producing one part, one part in multiple operations, or multiple different parts at the same time. All four different parts would be worked on by all three spindles before getting back to the load/unload station finished.

With three spindles, the machining operations can be varied as needed, adding to the machine’s flexibility. One rotation of the four-station pallet carrier can produce a complete part, four complete parts or a variation of the four. However, Mr. Porta says most of the applications use a progressive machining sequence.

Mr. Porta talks about one application where the customer did produce three different parts on one cycle of the Multicenter. “These parts went into an assembly, so each cycle of the machine produced a complete set of parts,” Mr. Porta says. “After machining, the parts were assembled and shipped to the customer. It was a very efficient application.”

Multicenter Compared with HMCs

HMCs are beginning to see increased investments in shops that are dealing with high-mix and low-volume work. They have inherent flexibility and adapt to automation easily using pallet shuttle systems to ferry work in and out of the machine tool. In addition the cutting tool capacity of the horizontal design is superior to its largest competitor, the VMC.

Survey’s conducted by Production Machining’s in-house market research business, Gardner Intelligence, show a significant uptick in HMC purchase projections; 85 percent more than the numbers for 2017.

However, Mr. Porta makes the point that if volumes and workpiece complexity demand more than one HMC, the Multicenter finds its niche. “It is a bridge between the very high production of a special-purpose machine and the lower volume with flexibility of an HMC,” he says. “The multicenter is in between these two classes of machine, and it is a standard machine tool, not a special, which makes lead times much shorter.”

The machine is designed for a 10-inch work cube, although the design is scalable for larger parts. Each of the three machining centers is served by its own tool changer, with a 12-tool capacity as standard on each. More tool capacity, up to 40 tools each, is available if needed. Each machine spindle has three axes at the tool tip and a fourth rotary axis is located on each worktable. All axes are controlled by the machine’s FANUC or Siemens CNC.

Smaller Footprint, Less Power

The design advantage of the Multicenter, Mr. Porta says, is that a typical customer for that machine, who needs three or four HMCs to hit its production numbers, can get them in a single platform. It’s easier to run the machine, it uses less power, and it takes less floor space.

Floor space requirements of an HMC, with its associated loading and unloading areas, is not insignificant. “Now, multiply that floor space by three and things get fairly large,” Mr. Porta says. “Because the Multicenter is essentially three HMCs on a single platform, it only occupies 87 square meters. We calculate three typical HMCs, with attendant automation, would take up 240 square meters.”

The Multicenter when compared with three stand-alone horizontal machining centers consumes 50 percent less energy, according to Mr. Porta. He cites consumption figures of 51 kWh for the Multicenter versus 120 kWh for three machining centers, with equivalent production.

These rates are justified by the reduction of redundant accessories, he says. For example, the machining centers drive three automation systems, 3 chip conveyors, and three pallet changers. Moreover, there is more maintenance associated with three versus one platform.

Two Target Customers

According to Mr. Porta, the Multicenter has two target customers. As the company was built on high volume, special machinery the Multicenter is designed to be a volume production center.

“Some of our customers dedicate the Multicenter to a single part, like a special machine,” Mr. Porta says. “These shops are manufacturing automotive quantities in the range of 700,000-1,000,000 parts per year in some cases. The inherent advantages of the three machining centers in one platform—cost reduction from less floor space, less energy and lower labor—still apply in these applications.”

Where the Multicenter differs from its special machine ancestry, is its ability to be cost competitive in lower volume applications. “Some of our customers use the Multicenter to fulfill production orders that are not high volume, but rather high mix,” Mr. Porta says.

For this second target group, batches from 500 to 5,000 are typical. These shops are generally not making parts for inventory, but rather fulfilling “spot” orders.

These shops tend to use the capacity of the Multicenter to respond to orders as they come in. The machines in these job shops are tooled for flexible production rather than dedicated production.

Quick-Change Workholding

The structure of the Multicenter is quite different from an HMC. The machine base is a weldment that Mr. Porta describes as a closed box structure. Inside the box, a four station rotary table carries the machining pallets. The box has three walls with a machining center module on each of the walls with its own set of linear guideways. The fourth wall is open for the load/unload station to access the workzone.

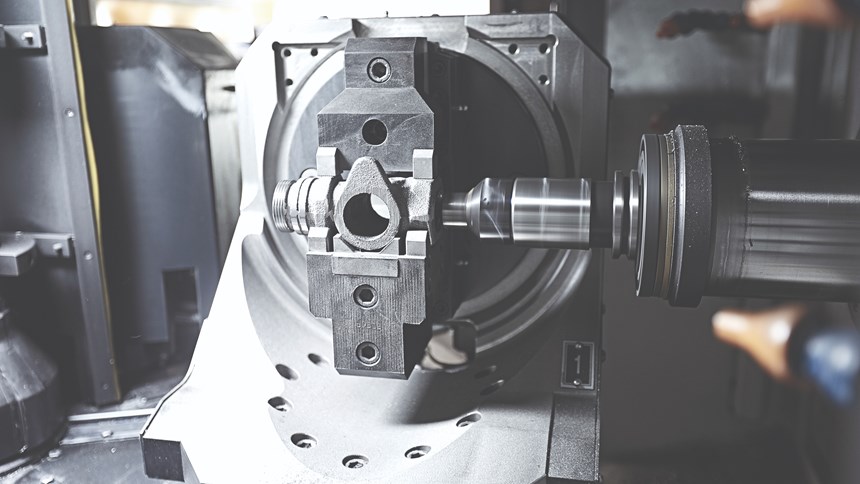

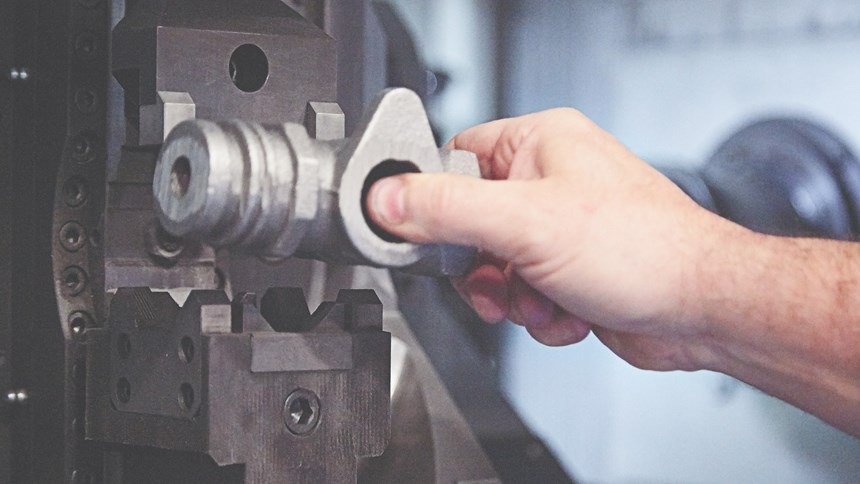

In developing the Multicenter, Porta has designed the workholding system to be flexible. Mounted on each of the machine’s three pallets is a receiver that can be indexed for position or continuously for contouring in B axis by the pallet. The receivers are standardized and remain in place on the pallet.

Clamps for the specific workpieces mount on the receiver and open or close under CNC and the hydraulics are constantly monitored by the control. Change-over is accomplished by simply replacing the clamps on the receiver. This results in a change-over time of 30 seconds.

For access to the fifth side of a workpiece the fixture is designed to index 90 degrees to expose that side of the part to the spindle. While this operation is usually done on spindle three, it can be done on all spindles if needed. The fixtures are also capable of a U-axis option if single-point turning is required to finish the part.

Running the Program

Programming for the three spindle Multicenter is relatively simple. Each machining center module has its own page in either the FANUC or the Siemens control, so its programming is basically one three-axis machine, with a B axis, at a time. Programming progresses from spindle one to two to three.

Even though there are effectively three separate programs running simultaneously, there is no need for a separate synchronization control. Both of the CNC brands that Porta uses operate synchronization of the programs in the control’s background.

Because the machine has three spindles and is usually running sequential operations, balancing cycle time to eliminate dead time is important. Porta has developed a software package with Microsoft that is called Energy Characterization.

Reading the power consumption from spindle motors, the software effectively reduces power for lighter cuts and transfers it, through regenerative braking, to the spindle using more power. The net result is optimized power consumption.

Porta is compatible with Industry 4.0 connectivity capability. Some of its development programs are relatively advanced. The information available, whether production is 1,000,000 parts or 500 parts, is of value to any manufacturer. Data is joining chips as the currency of metalworking manufacturing.

RELATED CONTENT

-

Machine Shop Leans on Rotary Transfer for Higher Efficiency

A firearm parts supplier’s lean manufacturing methods help it discover the many advantages of rotary transfer technology.

-

Rotary Transfer Offers Full OD Turning Between Centers

This small-footprint trunnion rotary transfer machine includes an isolated cell to perform full OD turning between centers for improved concentricity compared to flipping parts in a station for backside turning or moving the part to another clamping position.

-

Automated Manufacturing in the U.S. Makes for a Fitting Process

An Australian company has been able to speed delivery of its popular plumbing products to U.S. customers by adding machining and assembly cells to produce brass fittings in Alabama.