A Vacuum Cleaner For Machined Parts

The traditional process for removing cutting oils from parts has involved the use of chlorinated solvent-based cleaning systems. While such open-tank vapor degreasing with solvent-based cleaning technology works quite well, it is increasingly subjected to environmental regulations for emissions and disposal.

Along with other customer demands that precision machined parts producers face (tighter tolerances, smaller volumes and shorter delivery times), they also feel pressure to deliver clean parts capable of going straight to final assembly. The traditional process for removing cutting oils from parts has involved the use of chlorinated solvent-based cleaning systems. While such open-tank vapor degreasing with solvent-based cleaning technology works quite well, especially for cutting oils commonly used in precision machined parts manufacturing, it is increasingly subjected to environmental regulations for emissions and disposal.

In the mid 1990s, Germany-based Dürr Ecoclean developed an approach to solvent-based parts cleaning that uses non-chlorinated hydrocarbons in a closed-loop system under a vacuum. Successfully applied in Europe, where stringent environmental regulations have long been in effect, this cleaning system is finding interest in the United States as its regulations continue to tighten and demands for reliably cleaned complex parts increase.

Featured Content

In high school physics, most students learned that water boils faster on a mountain than at sea level. The difference is that atmospheric pressure (normally 800 to 1,000 millibars) is lower on the mountain, which allows water to boil at a lower temperature. Basically, this temperature/pressure relationship is the technological underpinning for Dürr’s hydrocarbon cleaning system.

The company has a line of self-contained free-standing machines that are sized based on throughput and volumes needed to be cleaned. These are batch machines with a throughput of approximately nine batches per hour for the smallest unit and 12 per hour for the larger machines. These throughput numbers are approximate and depend on the amount of cleaning needed.

In operation, a basket of parts is prepared for loading into the cleaning chamber. Parts can be randomly placed in the basket or racked. The unit uses agitation or, if needed, ultrasonics as part of the cleaning cycle to expose all surfaces of the workpieces.

The basket is placed into the cleaning chamber and a door closes. An internal lid covers the top of the basket inside the cleaning chamber. An initial vacuum of about 70 millibar is pulled for the first immersion in the hydrocarbon cleaning fluid. As the fluid fills the cleaning chamber for the initial wash, the basket can be programmed to rotate between 10 and 360 degrees with oscillation to agitate the parts. After the first wash cycle, the hydrocarbon fluid is removed from the chamber and passed through a 250-micron filter to remove solids.

A key advantage to cleaning in a vacuum is that the flash point of the hydrocarbon fluid increases, allowing more heat to be used to clean the parts that would not be possible without a vacuum. The nominal flash point of the isoparaffin fluid (similar to diesel fuel) for general cleaning is around 140°F. Under a vacuum, it can be safely heated to 170°F for more efficient cleaning. The higher temperature lowers the viscosity of the hydrocarbon fluid.

During the second wash cycle, optional cleaning operations can be performed, such as ultrasonic cleaning, if needed. The wash fluid is pumped out of the chamber through another finer filter (down to 5 microns), and the parts under high vacuum dry as the chamber is evacuated and any remaining residue is pulled out with the fluid. During this cycle, the work chamber is pulled down to a vacuum of 1 millibar. For reference, the vacuum of outer space is 0 millibar.

Next, the cleaning chamber is raised to ambient shop air pressure, completing the cleaning cycle. The door can be opened, and the next batch can be run.

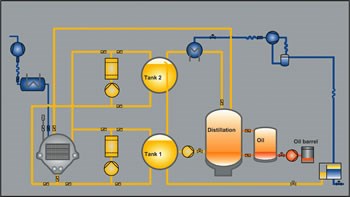

Dürr’s cleaning system is closed loop. The washing fluid uses a distillation process to separate the cutting oils from the hydrocarbon fluid. After the fluid passes through the filters for solids, it circulates to another chamber where the oil/cleaning fluid is heated. The cutting oil vaporizes at a different temperature than the cleaning fluid. The cleaning fluid vaporizes from the cutting oil and is returned to the filling tanks. The cutting oil is captured in a distiller tank where it is drained into a receptacle or barrel.

This continuous re-generation of the hydrocarbon produces no waste and allows the hydrocarbon to be used indefinitely. The only outputs from the closed-loop cleaning system are the metal fines captured in the disposable filters and the oil that is separated from the cleaning fluid.

RELATED CONTENT

-

What Does 2021 Have in Store for the Parts Cleaning Industry?

With a new opportunity to do good things in your organizations this year, I hope you use the parts cleaning section and this year’s and last year’s Parts Cleaning Conference as tools to succeed.

-

Ultrasonic Cleaning Basics: Technology, Solvents and Advantages

Ultrasonic cleaning technology is explained here as well as how to choose a type of ultrasonic machine for an application, the kind of detergent to use, and the advantages of using this parts cleaning method.

-

Automated Cleaning System Improves Productivity

This rotary basket washer drastically reduced the number of operators tending to the cleaning process as well as removed the bottleneck from that station.