Abrasive Developments for Centerless Grinding

These grinding wheels are designed for greater efficiency by achieving higher levels of stock removal per pass.

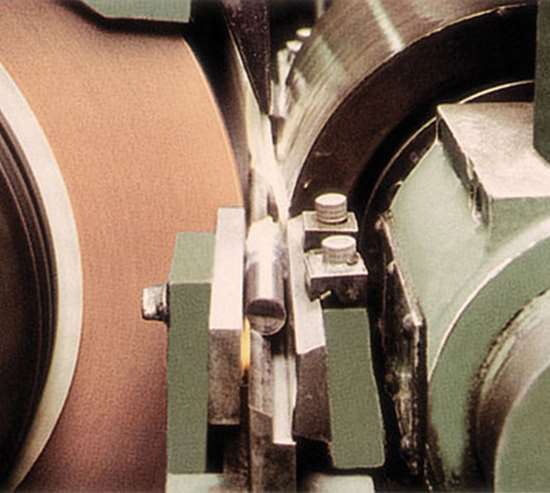

When it comes to attaining the best roundness, dimensional tolerance and surface finish for barstock, centerless grinding is the clear choice among machine operators. The throughfeed grinding process is especially important where parts must be produced efficiently, economically and within tight tolerances.

With these objectives in mind, Saint-Gobain Abrasives R & D engineers have developed Norton Century45 high performance wheels, designed to improve the cost-competitiveness of centerless grinding operations both large and small. The grinding wheels use ceramic, aluminum oxide and silicon carbide blends to grind barstock made from a variety of materials, including carbon steel, aluminum, cast iron, stainless steel 300/400 series, titanium, nickel alloys (Inconel) and copper.

Featured Content

The grinding wheels, with B45 vitrified bond, are specifically designed to yield better efficiency by achieving higher levels of stock removal per pass than conventional wheels—more than double in some cases. Removing the same amount of material with fewer passes means reduced cycle times and higher production rates.

New Grinding Bond

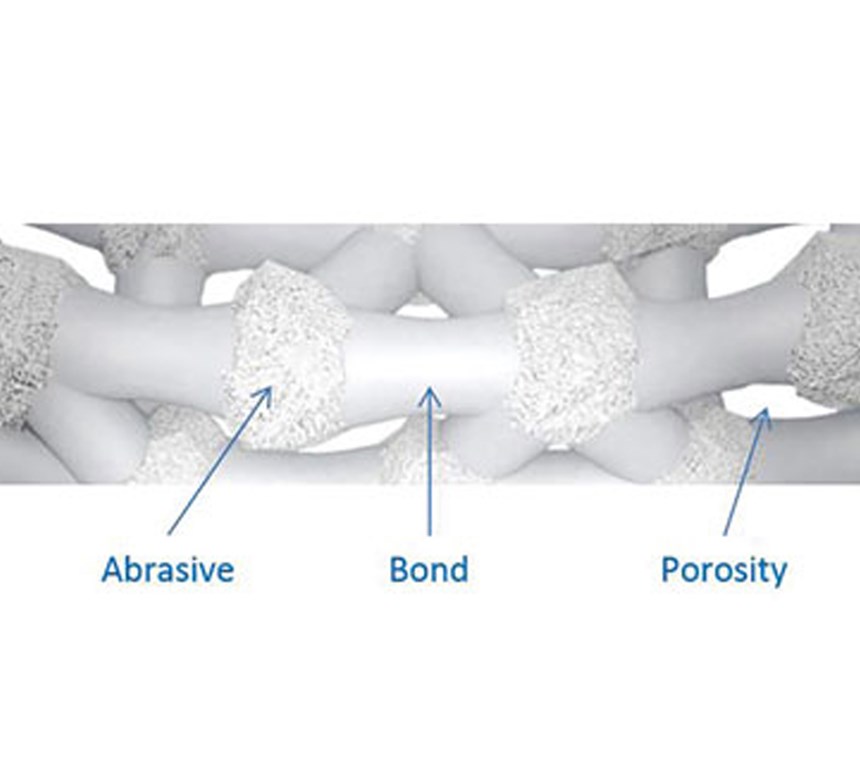

Organic abrasive products have two major components: abrasives and bond. The abrasive is the cutting tool portion of the wheel, and the bond holds the abrasive in the matrix to form the wheel. The space between the abrasive and the bond is referred to as the structure or porosity of the product (Figure 1).

The Norton Century45 centerless bond platform features a chemistry that is engineered to improve grain retention in the wheel. This technology enables wheels to be constructed with more porosity for a given hardness, directly translating into a wheel with the grain retention of a hard grade and the performance of a soft grade.

Longer Wheel Life

The best quantification of wheel life is the grinding ratio, or G-ratio. This specification is a measure of the amount of material removed as compared with the amount of wear of the wheel (refer to equation below). The amount of material can be measured in mass (grams or pounds) or volume (in3 or mm3) as long as equal units are used. This method removes any variation in production levels during the observed time.

Despite their work rate, Norton Century45 wheels are engineered for durability with maximum G-ratio and can last as much as twice as long compared with standard wheels. Fewer wheel change-overs result in less downtime, lower wheel inventory, reduced production costs and higher productivity.

Quieter Grind

According to the Bureau of Labor Statistics, approximately 30 million people in the United States are exposed to hazardous noise in their place of work. Noise-related hearing loss is consistently listed as one of the most prevalent occupational non-fatal illnesses in private industry. Every year, thousands of workers suffer from preventable hearing loss because of high workplace noise levels. The increased porosity of these grinding wheels offers a significant reduction in noise level while grinding hard metals such as Inconel.

The wheel has been shown to reduce grinding noise by 23.2 dB in some cases. To put this reduction in context, many commercially available foam ear plugs offer noise-reduction in the range of 25 to 28 dB.

Application Examples

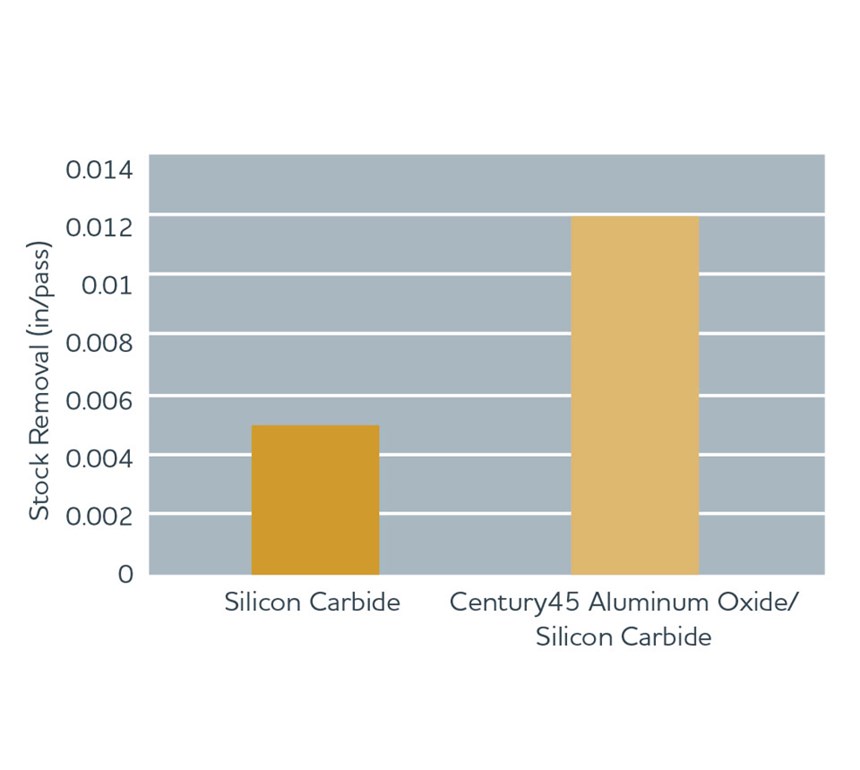

In a recent application study, the grinding wheel was introduced to improve the operation of the customer’s 40-hp Cincinnati Twin Grip centerless grinder, which is used for rounding and polishing Inconel barstock. Part OD was 0.5 inch to 1.75 inch and part length was 378 inches to 384 inches. The original 24-inch by 20-inch by 12-inch 80-grit silicon carbide resin bond wheel removed 0.005 inch of the Inconel alloy bar per pass. A Century45 two-wheel set—32CA60-PB45 (10 inches), 32CA80-PB45 (10 inches), with a removal rate of 0.012 inch per pass—was substituted in its place.

The new setup achieved not only 140 percent higher stock removal rate (Figure 2), but also a 100 percent improvement in wheel life, resulting in a 50 percent reduction in cycle time and significantly reducing noise levels during grinding (23.2 dB quieter than the incumbent). The new wheel demonstrated a total cost reduction of 30 percent over the incumbent wheel, resulting in an estimated annual savings of $98,800.

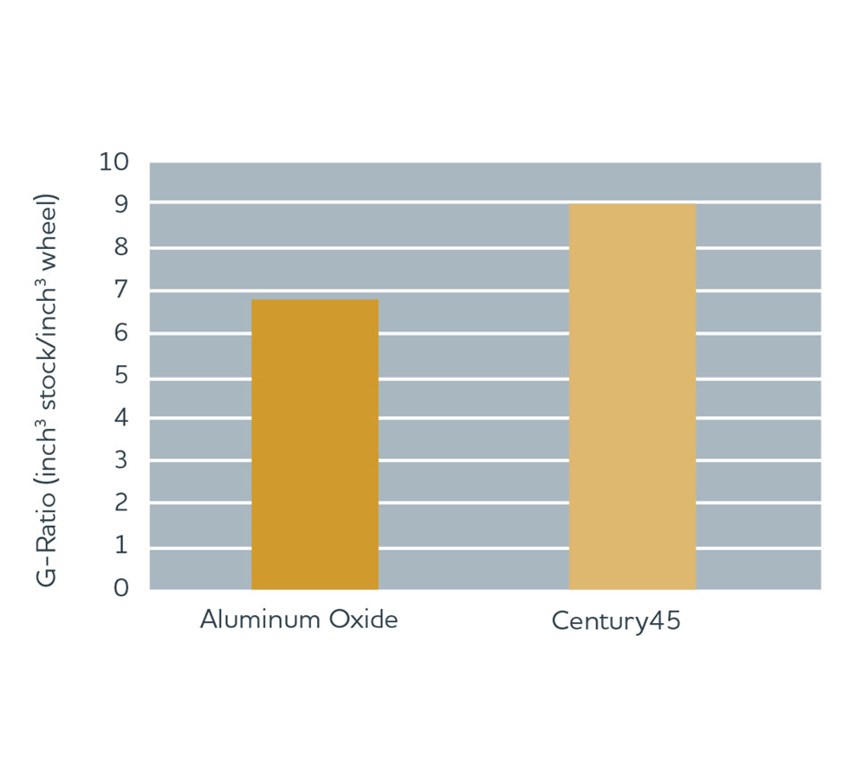

In another example, Norton was tasked to improve the abrasive life and decrease the overall costs of a 50-hp Cincinnati No. 3 centerless grinder used to round and polish the barstock of a variety of steel alloys, including 1045, 10V45, 4140 and 17-4. Part OD was 3.5 inches to 7.5 inches and part length was 4 inches to 6.5 inches. For purposes of the test, a Century45 wheel—3NQAC36-S9B45—was selected to replace a 24-inch by 8-inch by 305-inch 46-grit aluminum oxide resin bond wheel.

The new wheel produced a 25 percent higher stock removal rate over the incumbent wheel (0.005 inch versus 0.004 inch per pass) and a 32 percent improvement in G-ratio (Figure 3). The net result was a 100 percent performance/cost improvement over the incumbent wheel.

As shown in these case studies, selecting a more productive abrasive wheel can save significant amounts of time, effort and money in a grinding operation. Fewer wheel changes, less downtime and higher efficiency all mean higher capacity to handle additional jobs. Particularly for larger operations with multiple grinders, the productivity and remunerative dividends, can be quite significant.

RELATED CONTENT

-

Using Grinding Versus EDM to Finish Form Tools

Finishing carbide inserts using EDM or grinding.

-

Keeping Current with the Medical Machining Market

The medical machining industry being supplied by the precision machined parts industry is changing. This Northeast Ohio shop is working to keep up with the need to serve changing requirements of its medical customers by increasing the shop’s operational capabilities.

-

Grinding on a Swiss

This shop owner has developed a unique, and effective, approach to delivering a burr-free, tight-tolerance part.