The 168 Manufacturing FullShop FS40 system services up to 40 CNC machine tools by refilling coolant automatically when levels get low. Photo Credits: 168 Manufacturing

Have you experienced the frustration of attempting automated or lights-out operations on some of your CNC machine tools but failed because you couldn’t maintain proper coolant levels and/or concentrations? If so, you are not alone. Many machine shops still manually manage coolant, which makes consistent machining very challenging.

Precision Tool Technologies Inc. (Brainerd, Minnesota) is an example of a machine shop that manually refilled its CNC machine tools with coolant until management realized that its lights-out operations were not completely automated because of this one task they could not work around. It still needed to keep the lights on for some staff who came in on nights and weekends to refill the machine tools with coolant, even though the rest of the machining process was automated.

Featured Content

As a result, seven years ago this machine shop that provides contract, quick-turn and precision machining jobs to the optical industry began its quest to eliminate manual coolant management. Eventually, the company created FullShop, an automated coolant management system that delivers optimized coolant levels on a per-machine basis.

Once the machine shop was experiencing the rewards of hands-off coolant management — including smarter use of its skilled labor, higher CNC machine tool efficiency, fewer labor costs and no downtime — management wanted to share these benefits with other shops that are struggling with manual coolant maintenance. Thus, it created 168 Manufacturing, a brand of Precision Tool Technologies that markets FullShop.

Coolant management is one of the repetitive tasks that is often not done properly by operators, says Shawn Nelson, sales manager/business development at 168 Manufacturing. “If you can eliminate those dull, repetitive tasks (such as coolant management) that occur thousands of times annually in your shop, why wouldn’t you?” he asks. “You can take those minutes and align them with a production task that pushes revenue out of your business, making it more profitable.” In other words, automating coolant management frees up workers for more important tasks in the shop, much like other automation systems do.

A Universal System

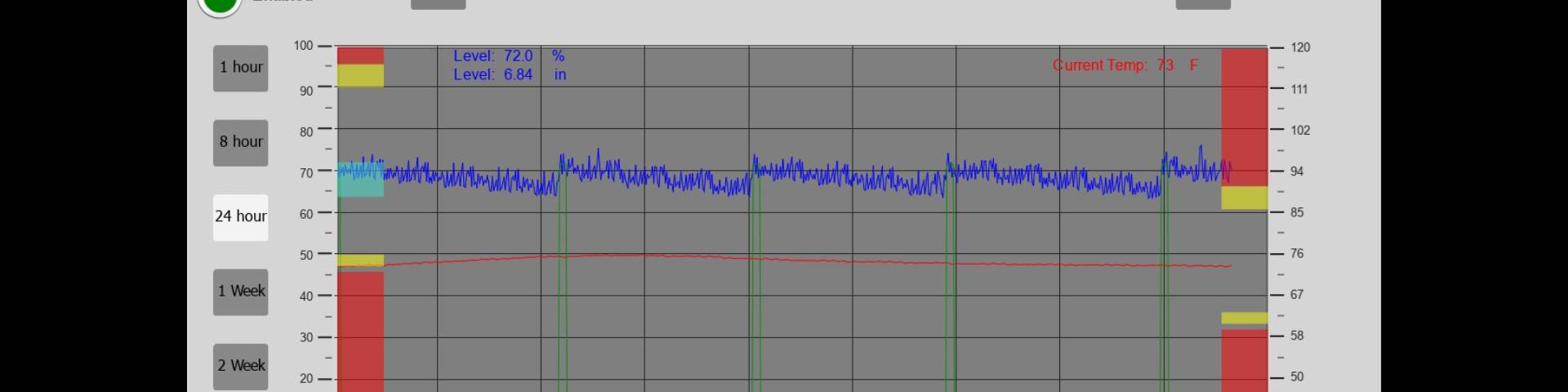

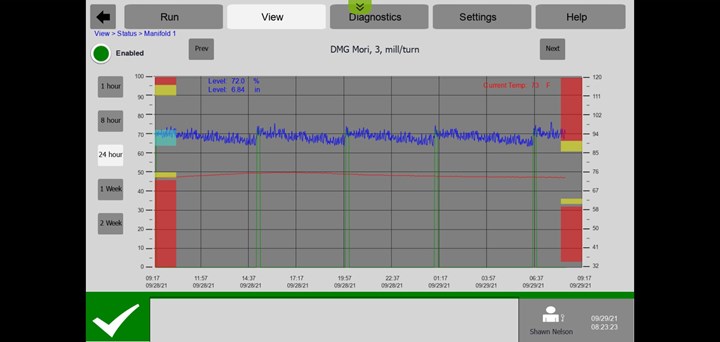

FullShop is a turnkey system that can be implemented on any machine tool. The system monitors the coolant level in the machine tool sump, then automatically replenishes the coolant before it runs low. Each CNC machine has an individualized coolant top-off ratio, which is optimized for each machining process. The FullShop controller automates the ratio control process, sump level management, water quality monitoring and usage reporting. The product also serves as a data collection, visualization and alerting system with built-in email capability.

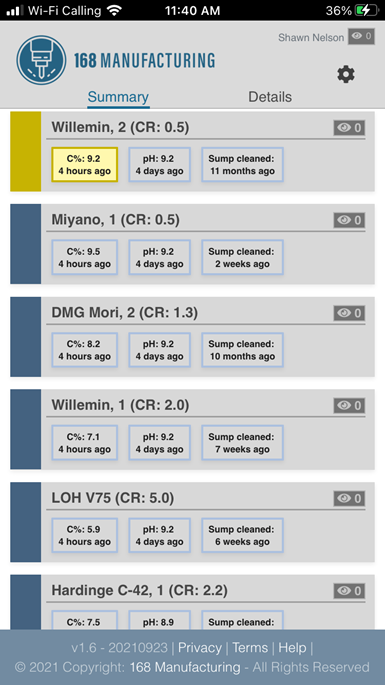

FullShop is used in conjunction with the company’s Coolant Health App that tracks key parameters such as concentration and pH, and advises the user regarding how to optimize the equipment.

168 Manufacturing offers two models: the FS120 system handles up to 120 CNC machine tools while the FS40 system services up to 40 CNC machine tools. These automated systems consist of the Coolant Health App, centralized pumping station, process controller, distribution manifolds and a small sensor that drops into a machine tool sump.

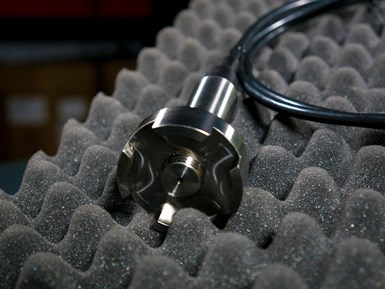

The sensor sinks down to the bottom of the sump and is wired to the data acquisition system, which is part of the remotely mounted distribution manifold. The distribution manifolds are offered in 24-station or eight-station configurations and are typically mounted in the building’s trusses near a

This sensor sinks to the bottom of a sump and collects data about the coolant. It enables an “out of sight, out of mind” attitude for the operators while also reporting critical information about coolant health to the machine shop.

cluster of CNC machines. Simple tubing is used to route fluids to each CNC from the distribution manifold. The remotely mounted manifold eliminates significant labor and linear footage of tubing and sensor wire, according to Nelson.

Machine operation and data trends can be accessed at the machine human-machine interface (HMI) or remotely with a smartphone, desktop computer or tablet wherever the user would like to deploy it. The trends and insight provided help customers further optimize their processes and businesses.

Although FullShop is an automated system, it is not completely hands-off. It is designed to help operators/managers adjust the coolant based on coolant data reported by the Coolant Health App.

The Coolant Health App shows trends in the coolant concentration in each CNC. With this information, operators can make offset decisions about coolant top-off ratios to optimize each individual machine tool. The app has proven to drive accountability for the data collection process with built-in notifications and alerts, and replaces outdated methods such as clipboards and out-of-sync spreadsheets.

Individualizing While Saving Time

Nelson explains that automating coolant management, as FullShop does, tends to the needs of each individual machine, which is generally not a regular practice at machine shops when coolant management is manual. That’s why it is normal for shops to end up with a wide bandwidth of concentration in their sumps when not implementing an automated coolant system. “Manually, no one takes the time to apply the math to how much of what ratio is needed for each top,” Nelson says.

Each CNC machine has an individualized coolant top-off ratio that is optimized for each machining process. The FullShop controller automates the ratio control process, sump level management, water quality monitoring and usage reporting.

FullShop also saves operators time and provides a stable process. It also eliminates human error and bad habits that often form when operators manually attempt to manage coolant.

Ideal Applications

Because the automated coolant system comes standard with remote connectivity, it provides valuable data to a machine shop, which can therefore help create conversations within these businesses about labor and machine utilization. “When selling FullShop, we are talking to the visionary leader in the business, someone who sets the tone for the overall company,” Nelson explains.

The Coolant Health app, which can be used on any smartphone, tablet or PC, collects trends and alerts shop personnel on key coolant parameters such as concentration, pH levels and date of the last sump cleaning.

By that, he means FullShop isn’t for everyone. It is mostly for companies running machines multiple shifts with more than a few machine tools that can benefit from freeing up people, having predictable coolant in their sumps and dreaming of more unattended machining.

Although this system does not come with “machine monitoring” per se, Nelson says its intelligent software produces charts for each machine tool that enables machine shop managers to analyze data and export it if they so choose.

An example of using the coolant data to learn more about the machine tool is when the software sends out email alerts when a sump level is getting too high, as predictive maintenance. This alert can prevent overflow, but it also shows there is often a problem with that individual machine, which is causing high coolant levels. At that point, an operator or shop manager can investigate the problem on the machine tool itself.

RELATED CONTENT

-

Handling Parts In A Robotic Cell

Here’s a review of the workholding and workhandling challenges a shop faces as it moves a part through a robotic cell, from serving up the blanks to the transfer of the final workpiece to post processing and gaging. Productivity, Inc. takes the reader through a few of their cells that they've installed using Fanuc robots and a variety of other machine tool equipment.

-

Job Shop Automation: Fast, Simple and Agile

When done right, automation can provide important benefits. Here’s a look at automation options to suit the varying needs of typical job shops.

-

What Is The Best Bar Feed System For Production Turning?

Selecting the right bar feeder can be one of the most important decisions a shop can make. Bar feed systems help improve productivity, throughput and quality, but in order to achieve the most benefit from them it is essential that a bar feed system be matched to the particular needs of the turning operation.