Beefed-Up Backworking on New CNC Multi-Spindle

This CNC multi-spindle automatic lathe includes a quillstock with six tool carriers and one counter spindle opposite the main six-spindle drum, allowing machining of complex workpieces in a single process.

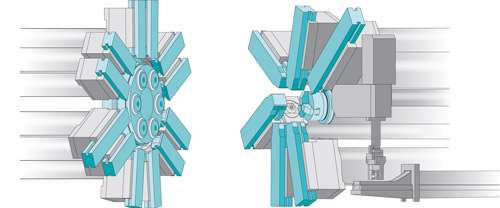

The new MS40P CNC multi-spindle automatic lathe from Index Corp. includes a quillstock with six tool carriers and one counter spindle opposite the main six-spindle drum, making it possible to machine complex workpieces requiring many tools with the highest precision in a single process.

The flexibility and capability of the machine is well-suited for batch production and for machining families of parts; the front and rear end machining options permit efficient, complete machining of production parts with complex geometry and/or extensive operations on the cutoff end.

Featured Content

The core of the machine is its compact spindle drum. Six fluid-cooled, infinitely variable hollow-shaft motors are able to drive as much as 40-mm barstock independently from each other. Other characteristics of the spindle drum are high torque, small frame size, maintenance-free operation, and an advanced synchronous design. The enhanced machine concept is based on the added A side (drum side) and an opposite quillstock on the B side.

Besides the tool carriers at the spindle drum side of the machine, six additional tool carriers and a counter spindle are located in the rigid monoblock quillstock. The tool carrier arrangement in the working area without a longitudinal slide block allows the use of more than one tool on each spindle.

The working area is clean and can be easily accessed through sliding doors on both sides of the machine. This is convenient for the user and greatly reduces setup time. Chips drop directly into the base of the machine.

The machine’s modular system allows, on the A side, customer-specific configuration of as many as 12 hydrostatic bearing-supported CNC cross-slides, several Y axes, and numerous stationary and live tools (for front-side machining), permitting a range of machining in a single setup, including off-center drilling, deep-hole drilling, thread cutting, angular drilling, cross drilling, contour milling, gear hobbing, and multi-edge turning. These are only a few of the many possibilities.

The characteristic V-shaped arrangement of the tool carriers means the optimum machining sequence is the only factor determining the process. For example, external and internal machining operations using stationary or live tools can be performed in every station.

During machining, users can program the optimum speed for each independent spindle, which can be varied during cutting. The result is excellent surface quality, short production times per piece and extended tool life. It is also possible to make speed changes during drum indexing, thus avoiding any additional secondary processing times. This capability also makes it possible to machine difficult materials that previously were hardly suitable for multi-spindle machines.

Should the machining options on the A side (spindle drum) not be sufficient, the extensions on the B side quill version come into play. Spindle positions 1 to 5 each have slides that can be used to machine the workpieces on the A side.

In position 6, there is a counterspindle traversing in the Z direction, so users can machine workpieces in positions 6.2 and 6.4. The slide 6.2 can also be used for machining the A-side or for rear end machining on the counterspindle with as many as three tools.

Tool position 6.4 also features a back-boring slide that can be equipped with three boring or turning tools, or with live tools. In total, as many as three tools can be used on the A-side, and another six tools are available for backwork machining.

Another advantage is the large Z-travel distance of the counterspindle, allowing longitudinal and transverse machining of longer workpieces (shaft parts).

A swivel unit places the parts on a conveyor belt that carries them away. The gripper can move across the part during rear end machining to save time. Instead of placing the finished parts onto the integrated conveyor belt, they can also be transferred to a handling system.

The MS40P extends the company’s multi-spindle machine series by another CNC multi-spindle automatic lathe that plays to its strengths with its flexibility and ease of retooling.

RELATED CONTENT

-

What’s Still Cam-Driven and Why?

Combining select cam-driven functions with CNC technology for this multi-spindle platform is said to help reduce machine cost while retaining high machining speed, precision and production.

-

Taking CNC Multis to a New Level

A visit to EMO, should be on the top of anyone’s list to see the latest in machining technology.

-

How to Get More Efficient Production from Swiss-Type and Multitasking Machines

SolidCAM for multi-axis Swiss type and multitasking machines provides a very efficient CAM programming process, generating optimal and safe Mill-Turn programs, with dramatically improved milling tool life.