Best Of Both Worlds

The proven advantages of wiper technology for indexible insert cutting tools continue to evolve. This article looks at some of them.

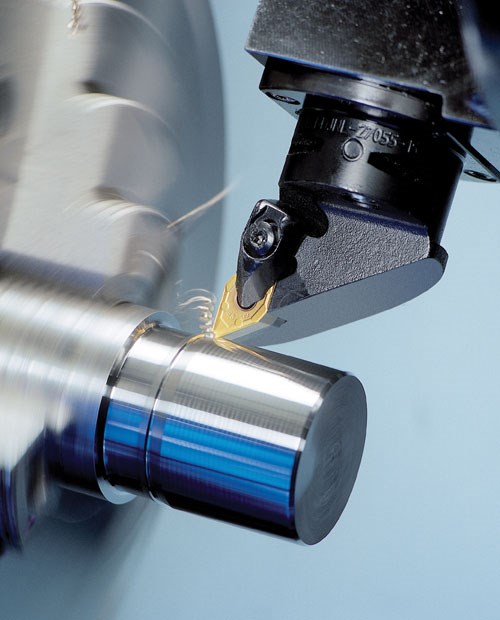

A seemingly universal challenge for turning applications is to achieve maximum productivity while meeting component specifications. A new generation of wiper inserts is building on the production success of previous wiper designs.

Turning with wiper inserts has become a widely established practice from finishing to roughing operations. Seemingly incompatible, the relationship between feed and finish on a single-point tool was changed by the wipers. With their introduction, cutting times were halved while still generating the same surface finish.

Featured Content

Today, this development is moving on, thanks to the introduction of the next generation of wiper inserts, which combine higher productivity with even better surface finish capability—the best of both worlds.

Wiper inserts play an important role because of the effect of conventional nose-radius inserts on the surface finish.

When turning with a single-point tool, the surface finish is determined by the feed rate and nose radius, as these are in a direct relationship to the profile height of the surface (Rmax). This means that the larger the feed, the rougher the surface generated by the edge of a given nose radius.

The wiper insert has changed this through the effect of its specially developed edge, which smoothes the scalloped tops that would otherwise have been

created.

Another important feature is its improved chipbreaking capability. The wiper geometries were also designed to combine good chip control at low feeds and smooth chipbreaking at high, productive feeds.

“Because of the larger cutting-edge engagement, wiper inserts in the early years gained an often unfair reputation for being more prone to vibrations,” explains Ronnie Löf, the Sandvik Coromant development engineer who is developing the wiper concept. “In fact, even with our early wiper inserts, the magnitude of cutting forces is only 5 percent higher, which means that only the more extreme cases of instability are affected negatively by the wiper geometry.

“Through the years, the perception that wipers cause vibrations has changed as applications have become commonplace,” he continues. “Today, however, there are different types of wiper inserts available on the market that do tend to generate more vibrations because of their long wiper edge. These inserts give a good surface finish at high feed rates, but they are good only for very stable setups.

“The objective for developing a new wiper generation was primarily to improve the level of surface finish that the insert could generate at a feed rate at least equal to the present,” continues Mr. Löf. Meanwhile, the tendency toward vibration was to be no greater than with earlier WM and WF inserts, and chip control and tool-life properties also had to be maintained.

“We needed to develop our existing wiper inserts because of shortcomings that were becoming apparent,” he says. “WM and WF were getting competition from wiper-type inserts that had longer edges and larger radii, especially when it came to surface finish capability. An increase in the main radius of the wiper edge was seen to be in line with the quality requirements of the machine shops. But the challenge was to limit the actual length of the wiper edge to what was needed to allow higher feed rates while not introducing the disadvantages of longer edge contact.”

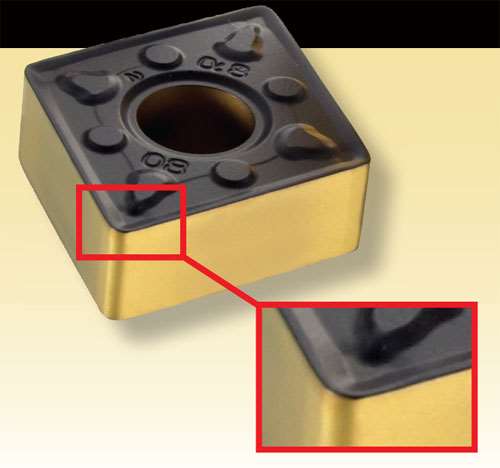

Developing a new wiper technology entailed designing a combination of the main radius and a complementary number and sizes of radii to establish the right wiper effect and to blend this correctly with the rest of the cutting edge.

“The new generation is called WMX and is a truly versatile wiper in that it covers most of the areas of the WM and WF and more,” Mr. Löf says. “The maximum feed rate capability is considerably higher, which means we can see a potential for some 30 percent shorter cutting times. And the WMX insert has been shown to give a surface finish that is much better than its predecessors at a maximum feed rate. Even at the lower wiper feed range, WMX can generate Ra values of below 0.5 microns.”

The newly developed wiper insert WMX is a solution for anything from finishing to roughing in general turning. It lifts wiper turning to a new level of productivity and results. The WM and WF wiper inserts continue to have a complementary function as optimizers, each having its peripheral strengths. WM has a strong cutting edge that is especially useful for interrupted cuts, while WF has a sharper edge with the capability for very fine cuts.

RELATED CONTENT

-

The Many Sides of Workholding

Here's a broad look at different ways to approach workholding, from bar feeders to collet chucks to robotics.

-

A Guide to Insert Coating Processes and Materials

Few materials have had a greater impact on our economy and industrialized culture than cemented tungsten carbide.

-

4 Strategies for Managing Chip Control

Having strategies in place for managing chips is an important part of protecting the production process, from tool life to product quality.

.png;maxWidth=970;quality=90)