Collaborative Robots for DIY Automation

Next-generation, new-generation, co-worker — call it whatever; there is a robotics revolution rolling into manufacturing, warehousing, materials handling and supply chains worldwide.

#Industry40

When asked how they envision a robot, most people either think of huge, unwieldy robots working in fenced off areas in large factories. Or, they think of futuristic cyberbots mimicking human behavior.

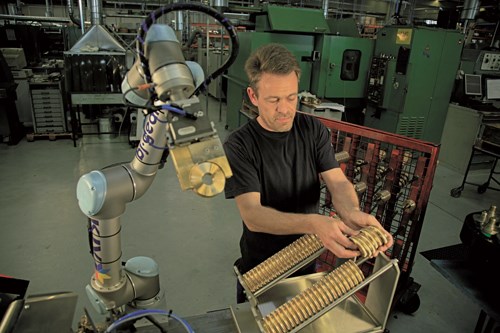

But somewhere in between these two scenarios lies a new emerging reality in the form of a new class of robots, dubbed “collaborative robots.” The name comes from their ability to work directly alongside employees with no safety caging.

Featured Content

These kinds of cobots are poised to bridge the gap between fully manual assembly and fully automated manufacturing lines. Nowhere is that more obvious than in the small to medium business (SMB) sector, that has often been inclined to view robotic automation as too costly and complex to consider.

However, unlike the traditional image of robots working behind glass cages at automobile plants and other big assembly lines, collaborative robots are lightweight, flexible and can easily be moved and reprogrammed to solve new tasks, meeting the short-run production challenge faced by companies adjusting to ever more advanced processing in smaller batch sizes. The automotive sector still comprises roughly 65 percent of all robot sales in the U.S., while RIA (Robotic Industries Association) quote observers believing that only 10 percent of companies that could benefit from robots have installed any so far.

Lowering the Entry Barrier

The reason that number is so low is primarily because of three challenges that are now being addressed by the new collaborative robots: cost, user friendliness, and applicability. Let’s start with the financial issue.

Even where workers are affordable, the next generation of complex products will require task adaptability, precision and reliability that is simply beyond the skills of human workers. According to the old rule of thumb, the cost of a robot would be equivalent to one worker’s 2-year salary.

The new wave of collaborative robots are closer to one fourth of that price. Combine that with the faster turnaround time that robots bring to the workplace, and robotic technology demonstrates that the offshore exodus make increasingly less business sense any longer. Instead, the new robots become a high-tech currency that’s changing the wage wars into a competition over increasing product quality and quick turnaround.

DIY Automation

With traditional robots, the capital costs for the robots themselves account for only 25 to 30 percent of the total system costs. The remaining costs are associated with robot programming, setup, and dedicated, shielded work cells. What shops are finding is the “out of box experience” with a collaborative robot is typically less than an hour. That’s the time it takes to unpack the robot, mount it, and program it for its first simple task.

This leads to user friendliness. Instead of requiring skilled programmers, this new class of robots comes with a tablet sized touchscreen user interface, where the user guides the robot arm by indicating movements on the screen.

Or, programming can be accomplished by simply grabbing the robot arm, showing it the desired path of movement. The interface is compliant with most industrial sensors and programmable logic controls (PLC).

Programming for new tasks is easy, as experienced by BJ Gear in Denmark, one of the world’s leading manufacturers of special gears, precision gears and transmissions. BJ Gear has acquired four collaborative robots from Universal Robots (East Setauket, New York) and found them user friendly and intuitive enough to operate that employees themselves have learned how to program and adjust the robots for routine and new tasks.

Rapid Payback

Instead of investing in new machinery, BJ Gear had the UR robots automate a functioning machine. It is an older Gratomate gear deburring machine that was given a new lease on life by means of the installation of a UR5 robot that fully automates the entire process of deburring and stamping of gear wheels and finishes workpieces for further assembly.

It is able to replace an employee who would previously have to insert the gear wheels into the Gratomate and subsequently turn them, so they could be deburred on both sides, and finally manually stamp each gear wheel. Today, employees at BJ Gear only have to remember to keep the chamber full. This frees the employee to perform more value-added tasks.

Every gear size has approximately 100 various combinations, and therefore a large number of product variants. BJ Gear manufactures extremely complex high-end products with finer tolerances than most others, offering its customers production of a small series. Its use of collaborative robotics gives BJ Gear the opportunity to automate tasks, even with smaller volumes and more complexity.

The first UR robot that BJ Gear purchased in 2009 was for use in its production cell. It has proven to be extremely reliable and has paid itself off a long time ago. The purpose of this particular robot was to optimize the work process in order to feed raw workpieces into the chamber of the CNC machine and receive a finished product at the other end.

BJ Gear had three functional, but older machines: a lathe, a cutter and a washing machine. These machines lacked any automation and needed constant manning as it took an employee to feed workpieces into the lathe chamber and subsequently take the processed workpieces and place them in the cutter followed by the washing machine. BJ Gear could have replaced these machines with a fully automated multitasking machine, however, this would have cost 15 times more than the robot solution from Universal Robots.

Today, it only takes one employee to make sure the chamber with items at the CNC lathe is full. The conveyor belt and the robot handle the rest. This means that BJ Gear is able to produce 100 workpieces at a time without human intervention, increasing production speeds. Now, the same employee is able to handle another production cell and take care of filling and quality control of both cells at one and the same time.

BJ Gear’s Plant Manager Björn Sommer explains that this has enabled the manufacturer to keep production in Denmark. “We are constantly trying to optimize the production flow and had for several years been looking for automated solutions for BJ Gear. Previously, we were reluctant to acquire robots as they were so costly that the payback time would be far too long for a small company such as BJ Gear. Universal Robots changed this. The flexible lightweight robots—UR5 and UR10—are reasonable enough in price that they provide a pay off in a relatively short time period. These machines have proven to be easily implemented in various places in production because they can run entirely without any safety shield. Our calculations show that the ROI for one of our robots will be covered in less than 1 year.”

Safety First

Safety has been a hot issue and the major thrust of research and development in robotics labs for some time. With human collaboration in mind, the new generation of industrial robots consists of rounded joints, back drivable motors, force sensors and lighter weight materials.

In another application, a UR is used to pick metal parts out of a press brake. It was able to solve several automation headaches at Etalex, a Canadian manufacturer of shelving systems, which had no room on the shop floor for safety guarding in front of the press and needed a flexible user-friendly robot able to safely handle the pick-and-place tasks in a high traffic area. It was an ideal application for a collaborative robot.

Compared with the other 25 robots in operation at Etalex (all placed behind sturdy safety guarding) the Universal Robots application is an unusual sight. Because the collaborative robot can work right alongside employees, there is no need for safety fencing because of innovative force-sensing technology that enables the robot to automatically stop operating if it comes into contact with employees. The lightweight UR robots can quickly be moved and reprogrammed and are currently applied as needed in 10 different production applications at Etalex.

Frees up 7 Man Hours per Day

Before Etalax invested in collaborative robotics, an employee would manually unload the press brake 8 hours a day. These repetitive tasks have now been reduced to an hour daily spent on inspecting the quality of each pallet and coil changing, resulting in an estimated 12 months ROI.

Machine operator at Etalex, Richard Clive, explains how the UR10 has made the workplace much safer. “Previously, you had to put your hands close to the brake press. There’s always a chance of an accident happening. With our load/unload robots, there is no chance of anyone getting injured.”

New Way of Approaching Robotics

These examples show the flexibility of applications for this new generation of robots. They are helping solve real-world manufacturing challenges that may not have been seen as viable uses for robots. Eliminating the safety cage between the man and machine opens up many other possible uses for collaborative robots.

When it comes to human interaction, automation and flexible manufacturing, features of the classic industrial robot must evolve on almost every level: from fixed installation to the ability to relocate; from periodic repeatable tasks to frequent task changes; from intermittent to constant connectivity; from no interaction with humans to frequent collaboration with workers; from space separation to space sharing; from profitability within years to near-immediate ROI. The near future will see even more advances in this nascent field of robotics, changing the way we work and interact with technology.

RELATED CONTENT

-

Cobot Gripper Considerations

There are a variety of ways for collaborative robots to pick up and hold parts and materials. Here are four.

-

Machine-Tending Cobot Fills Night Shift

A collaborative robot helped this shop run a machine tool 24/7 when hiring someone for a third shift didn’t seem to be an option.

-

Replace Repetitive Measurement With DIY Robotic Automation

After minimal training, a shop can learn how to use this robotic inspection system configured for a shopfloor application to supersede repetitive, time-consuming, high-mix gaging processes. It can then be redeployed for another application somewhere else in the facility.

.jpg;maxWidth=970;quality=90)