Continuous Improvement Streamlines Throughput on CNC Swiss-types

Applying continuous improvement is how this Swiss shop keeps ahead of the crowd.

Family-owned Des Plaines, Ill., manufacturer C&L Supreme has evolved since 1957 from a job shop primarily engaged in the production of aftermarket automotive components to a reliable manufacturer of diverse, high quality and complicated precision parts. Founded as Supreme Manufacturing, the company changed its name to C&L Supreme after acquiring C&L Screw in 1972.

The company then pounded out millions of screw machine parts per year on Brown & Sharpes for a full decade until current owners Phillip & Peter Spizziri committed to CNC technology in the early 1980s. Their adoption of CNC technology before it was widely embraced by other manufacturers exemplifies the organizational quest for continuous improvement that drives the company’s success.

Featured Content

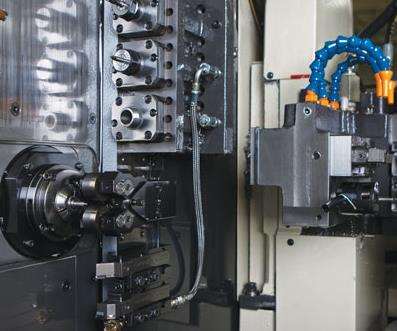

Combining a dedication to continuous improvement with a work environment that encourages resilience and flexibility has allowed C&L Supreme to transition smoothly through many phases of change. With a modern 20,000-square-foot facility and staff of 32, the company today manufactures a variety of parts from carbon and stainless steels, aluminum and brass, including intricate audio components, shafts, rollers, forgings, castings, valve bodies, mounting plates and brackets. It operates more than 25 CNC machines, uses advanced measurement and inspection technology, and holds ISO 9001:2008 certification.

Making the shift in the 1980s from automatic screw machines to productivity-enhancing CNC lathes established the company’s solid reputation as a reliable, quality supplier. Through the past 20 years, as it became evident that less complex volume work was starting to move not only out of the Chicago area, but also out of the United States, management has directed its thoughts toward continuous improvement with a new seriousness.

Dealing with Reality

“Jobs for simpler parts were simply disappearing. We decided that the old way of doing business was disappearing, too,” Operations Manager Gary O’Gradney explains. “Higher complexity components in shorter runs with less lead time were clearly the future.”

To remain successful in an environment that would offer reduced opportunity and more competition for production runs, the company focused on providing value-added operations to components and assemblies. Their goal was to help contain costs and improve quality control by reducing multiple sourcing and handling. Assembly, painting, plating and heat treating are some of the processes that C&L Supreme added to its list of capabilities as it acquired new technology and supply chain relationships to achieve that goal.

Acquiring a more flexible Swiss CNC business platform was moved to the top of the agenda when it recently re-evaluated its use of technology, which already included an array of Swiss and non-Swiss CNC machine tools. Mr. O’Gradney identified several areas of need.

First on his list was the part application. Current methods of turning several parts required secondary operations. The machine they wanted would need to have multiple axes, be capable of machining parts as large as 20-mm diameter and have a high pressure lubrication system. Second, programming and operation would need to be easy. And third, reliable service and training resources were strongly desired.

Reducing Part Operations

“When we began looking into the purchase of new Swiss technology to machine valve stems, we identified specific items that required justification,” Mr. O’Gradney explains. “Reducing part operations were the primary concern.” Headstock stroke length was also important as some of the stem lengths exceeded 7.0 inches (178 mm).

The ability to program parts offline was also essential, as was post sales service support. “In the end, we selected a Tsugami SS 20 Super Swiss Turn from REM Sales,” Mr. O’Gradney says. “It satisfied all of our requirements, and the SS platform offered the most flexibility moving forward.”

C&L Supreme’s continuous improvement team recommended switching the production of a family of valve stems to the new machine. Cut from 303 stainless, the group consisted of four parts ranging in size from 5 inches to 7 inches in length. The parts featured a long turned diameter with threads at both ends and a cross-hole immediately before the larger of the two thread rolled diameters.

Up to this point, the stems were blanked on a gang-tooled lathe in about 1 min., prior to thread rolling. Single pointing was not an option, as the customer spec required a degree of material strength that could only be achieved through thread rolling. The part was then burnished, an abrasive polishing process, to a 3-micron finish. Polishing sometimes required multiple passes through the burnishing machine.

“We thought that consolidating as many operations as possible into one machine would significantly improve part quality,” production supervisor, Jeff Johnson, says. “Any time redundant setups are eliminated, part quality improves.”

Sometimes it Takes a Village

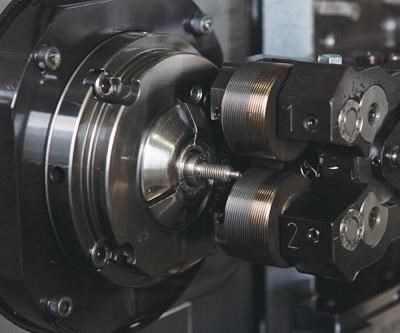

Familiar with single pointing, but not thread rolling on a Swiss turn, Mr. O’Gradney and Mr. Johnson turned to Scott Hauser, REM Sales account manager, for suggestions. After carefully studying the process, Hauser suggested the integration of two thread rolling heads from LMT Fette on the new Swiss machine.

“The process required axial and tangential thread rolling,” Mr. Hauser says. “A tangential attachment was affixed to the main gang slide for the front of the part, while an axial attachment was added to the backworking arm to handle the end of the part.”

The Fette thread rolling heads proved their worth by eliminating the secondary thread rolling operation entirely. “By experimenting with different approaches to turning, we were able to produce an almost complete surface finish,” Mr. Johnson says. “In most cases, multiple burnishing operations were reduced to one single pass through the machine.”

The company was able to conclude the process prove-out rapidly. The new process removed the secondary thread rolling and shortened burnishing time. Secondary quality issues were also eliminated because fewer people now handled the parts. “In the past, parts had often been nicked while queued for thread rolling,” Mr. O’Gradney says.

“Prior to the development of this new process, quality issues were often identified after thread rolling,” Mr. Johnson adds. “We now have much better visibility of the process and can reduce scrap by making corrections earlier.”

C&L Supreme is pleased with its choice because of the machine’s capabilities to streamline operations and its contributions to the company’s goals of reducing production costs and improving part quality. The new Swiss machine’s modular tool zone and ease of operation meets the company’s requirements for future flexibility and adaptability.

As the business moves forward in sync with changes in the marketplace and technology, its long history of success is testament to the value of continuous improvement and management’s recognition that the best businesses and technology revolve around the customers’ needs, not the other way around.

RELATED CONTENT

-

New Line of Swiss-Types for Job Shops Eyeing High-Production Work

Mazak now offers the Syncrex line of Swiss-type CNC lathes — its first — targeting machine shops getting into higher volume production of complex parts.

-

Workholding For Swiss Turning

In large part, because of the machine’s versatility, Swiss turning is increasing its penetration of the precision turned parts market. As more shops look to this technology, a look at workholding considerations is in order.

-

6 Tips for Training on a Swiss-Type Lathe

There are nuances to training a person to effectively operate a Swiss-type lathe. A shop I visited a while back offers some suggestions.