Cutting Tools Enable Team Penske to Perform More Aggressive Roughing

Team Penske's cutting tools caused extended cycle times in roughing performance racing parts. Tungaloy's DoFeed and TungMeister cutters reduced cycle times, the predictable tool wear easing unattended machining.

Team Penske is one of the country’s most successful professional automobile racing teams. Dating back to its first race in 1966’s 24 Hours of Daytona, cars owned and prepared by Team Penske have produced more than 420 major race wins, more than 480 pole positions and 28 national championships in open-wheel, stock-car and sports-car racing competition.

Its machining facility in Mooresville, North Carolina, is not a job shop. However, it functions similarly in that it doesn’t produce parts in high volumes, but instead machines small batches (even one-offs) of new race car components that the team’s engineering department has designed to improve performance, such as new suspension, chassis, and steering or brake system components. The shop also machines parts for fixtures and pit equipment, as well as wind-tunnel models, and molds and patterns for composites parts.

Featured Content

Component materials are wide-ranging, too, including aluminum alloys, low-carbon and alloy steels, stainless steels, titanium, epoxy tooling board, and plastics such as nylon and Delrin. The shop uses a range of Mazak equipment, including VMCs, five-axis machines, live-tooling lathes and multitasking Integrex turn-mills.

“Vehicle weight is critical,” says Matthew Gimbel, production manager for Team Penske. “Over the years, we’ve gone from simple, laser-cut parts to fully machined and pocketed components to minimize overall part weight. It’s also critical to position the weight as low as possible on a car to improve performance. So it’s beneficial whenever we’re able to remove weight from a component installed high on the car and add weight to the weight boxes low on the car.”

Effective roughing operations are key to speed the machining of these parts, because in some cases as much as 95 percent of a billet of material is removed to complete the part. To that end, Team Penske has found that the Tungaloy DoFeed high-feed cutters and TungMeister end mills with exchangeable heads offer key design elements to perform aggressive roughing operations, thereby speeding the production of new components. In fact, Tungaloy America is a preferred supplier as well as a technical partner for the team’s NASCAR and Indycar racing programs, providing tooling advice to enhance efficiency and accelerate machining for the team’s various manufacturing processes.

According to Tungaloy, the DoFeed’s effective roughing capability is due in part to its geometry that applies the chip-thinning concept. Chip thinning depends on the lead angle of a milling cutter, as is shown in the image in the slideshow at the top of this article. A cutter with a 90-degree lead angle has no benefit of chip thinning, because a feed per tooth of 0.0078 inch (0.2 mm) delivers the same 0.0078 inch (0.2 mm) of chip thickness. For a cutter with a 45-degree lead angle, a feed per tooth of 0.0098 inch (0.25 mm) creates a chip thickness of 0.007 inch (0.178 mm), which enables the feed rate to be increased to reduce cycle time. However, a DoFeed cutter running at a feed per tooth of 0.05 inch (1.27 mm) provides chip thickness of only 0.007 inch (0.178 mm), further reducing cycle time.

DoFeed cutters are also said to offer lower cutting forces. Because a cutter’s lead angle determines the direction of the cutting force, the direction of the cutting force for a 90-degree tool is perpendicular to the spindle, putting increased pressure on the tool. The cutting force for a 45-degree tool is directed toward the spindle, but at a 45-degree angle. DoFeed cutters direct the cutting force nearly parallel and back toward the spindle due to their acute lead angle, which means less pressure is exerted on the tool.

Mr. Gimbel points to a few examples of how the shop benefits from these particular Tungaloy tools. One is a rear suspension panhard bar slider, in which 95 percent of a steel billet is machined away. Roughing time for this component using a DoFeed 1-inch, five-flute tool with multi-purpose grade AH725 inserts, followed by a TungMeister 0.5-inch, two-flute with AH725 inserts, is 36 minutes. The DoFeed cutters produce 10 parts per insert edge and the TungMeister produces five parts per insert edge.

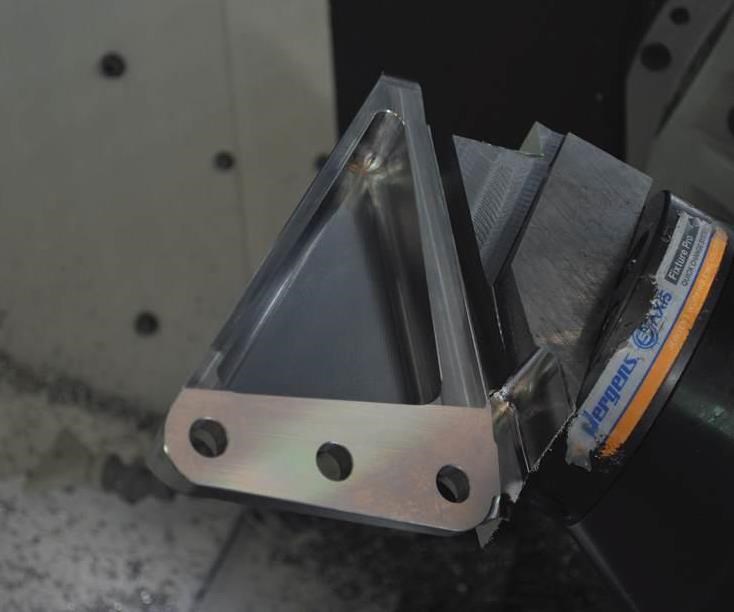

A second is a brake caliper mount machined from 17-4 stainless steel, in which 90 percent of material is machined away. After switching to the previously mentioned TungMeister tool, overall cycle time was reduced by 50 percent, because it saved 20 minutes of roughing time per part. In addition, the tool provided effective chip control when machining deep pockets to eliminate chip packing. “Even with deep pockets, we have the confidence to run these parts unattended, because we know that the tools will last,” Mr. Gimbel says. “These tools also enable faster cutting-tool changes, because only the cutting head is replaced, not the entire tool.”

Another unattended machining example is a steel engine mount in which 82 percent of a billet of material is removed. This part has a unique geometry in that no exterior surfaces are orthogonal or parallel to one another, and its five holes are kept within 0.003 inch of each other. Although five-axis machining is the most efficient way to maintain the hole-location tolerances and remove the majority of the material, cutting speeds were a concern because of long tool lengths needed. Fortunately, the low cutting forces generated by the DoFeed tools (2-inch, five-flute and 5/8-inch, two-flute DoFeeds with AH725 inserts) enabled the shop to maintain cutting speed during the roughing cycles, even with extended toolholders. “In addition, tool durability, and predictable and consistent tool wear again enables us to run our shop lights-out.” Mr. Gimbel says. “We’re confident that we can leave the machines running after hours.”

Team Penske benefits from other Tungaloy tools, too. “Tungaloy offers a better range of boring bar sizes in its Mini Force turning line, so we were able to expand our solid carbide coolant-through boring bar selection while reducing the number of inserts in inventory, since the boring bars used the same type,” Mr. Gimbel explains. “Plus, the cost per cutting edge is 7 percent less than the four-sided inserts that we were previously using.”

RELATED CONTENT

-

Advances in Swiss-Type Technology

R&D efforts in recent years have led to higher efficiencies, increased agility and expanded capabilities for shops performing Swiss-type turning.

-

A Race to the Machined Part (Surface) Finish

To improve component finish as well as engine and gearbox performance for its customers, this racing motorcycle rebuild company uses a super-finishing process for gears and related components which is more commonly used for aerospace and jewelry applications.

-

The Dirt On Cleaner Crankshafts

A high-pressure waterjet blasts away burrs and machining residues that resist more traditional cleaning methods.

.jpg;width=70;height=70;mode=crop)