Gains In New Equipment Installations Vary By Country

The World Machine Tool Output & Consumption Survey

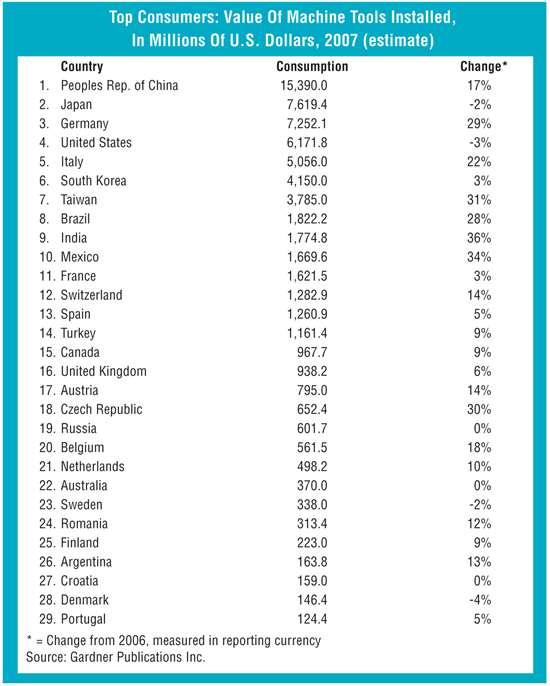

If you believe that this year’s new machine tool is more productive than last year’s, then the pace at which countries purchase and install the latest factory equipment has implications for international competitiveness. During 2007, the countries most involved in metalworking manufacturing boosted their consumption of new machines by an average of 16 percent.

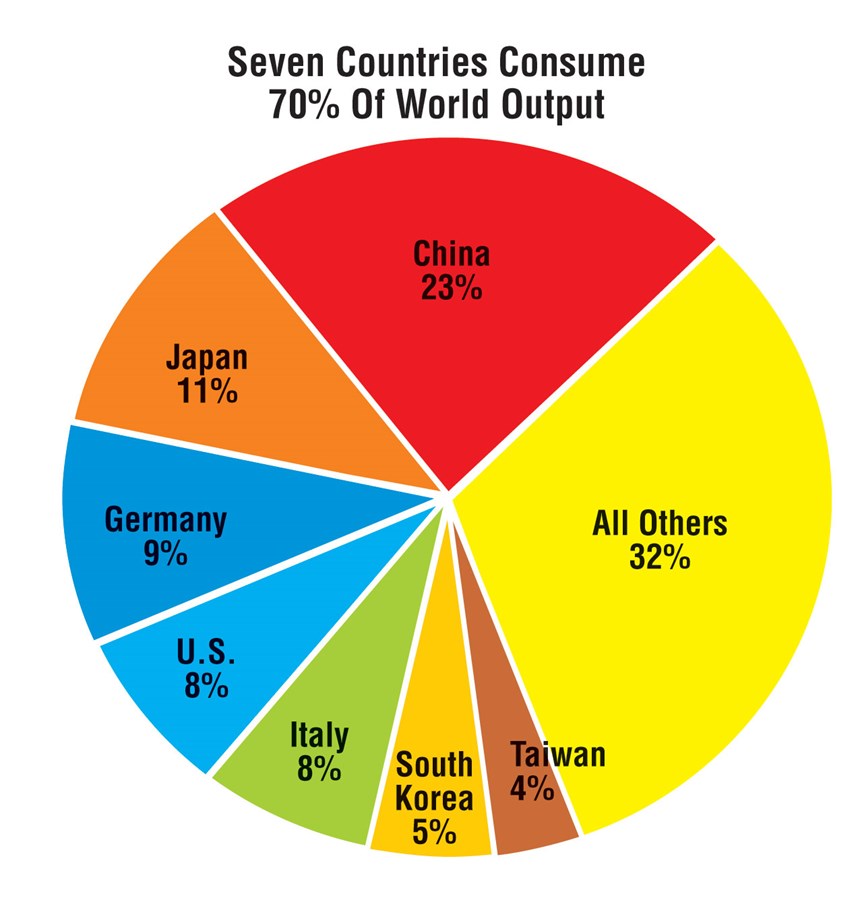

China once again is a stand-out: Since 2002 it has ranked at the top in consumption, and last year its $15.4 billion worth of installations grew by $2.3 billion. That year-to-year increase, by the way, was higher than the total machine tool consumption in Brazil, India or Mexico. The 17-percent growth in Chinese consumption follows several years of double-digit percentage increases, some as high as 40 percent per year. Simply put, China last year took in almost one-quarter (23 percent) of the value of all machine tool production tracked in our annual survey.

Featured Content

China was not alone in its growth. In other parts of Asia, Taiwan (more than 31 percent growth) and India (more than 36 percent growth) also saw exceptional increases in new cutting and forming machines shipped into their metalworking factories (see Top Consumers table). Very significant percentage increases also are seen in Germany, Italy and Brazil.

The international statistics come from the 43rd “World Machine Tool Output & Consumption Survey” (“WMTO&CS”), conducted annually by Gardner Publications Inc., the publishers of Production Machining. The “WMTO&CS” measures shipments, trade and consumption from major industrialized nations.

The great majority of the 29 countries in this year’s survey showed an increase in consumption. Consumption, in this case what economists call “apparent consumption,” is derived from taking the local production from a country’s own machine tool factories, adding in its imports and subtracting out its exports. What remains is assumed to have been installed, or consumed, internally.

The United States produced $3,578 million in its own machine tool factories; it brought in $4,254 million from Japan, Germany, Taiwan, et al., and it shipped out $1,660 million to customers in Mexico, Canada, China, et al. So the U.S. can be said to have consumed $6,172 million worth of products in 2007. That number, however, is down 3 percent from the previous year’s consumption, and if that decline were to become a trend, it could mean more erosion of the manufacturing base in the U.S., which until the year 2000 had been far and away the world’s leading consumer.

Keeping America internationally competitive in metalworking by installing new, up-to-date factory equipment is a key reason many manufacturing executives are praising the economic stimulus package that Congress passed and the president signed into law in February. The new law offers firms bonus depreciation for new capital expenditures like machine tools that are put into service this year, and it boosts how much small businesses can write off for new equipment.

If tax incentives are one reason to be at least a little bullish about U.S. factory-equipment installations, another would be the fact that orders have been continuing to grow. Tracked by a monthly survey conducted jointly by the American Machine Tool Distributors’ Association and AMT – The Association For Manufacturing Technology, U.S. bookings for selected machinery types actually rose during 2007, increasing backlogs in some instances.

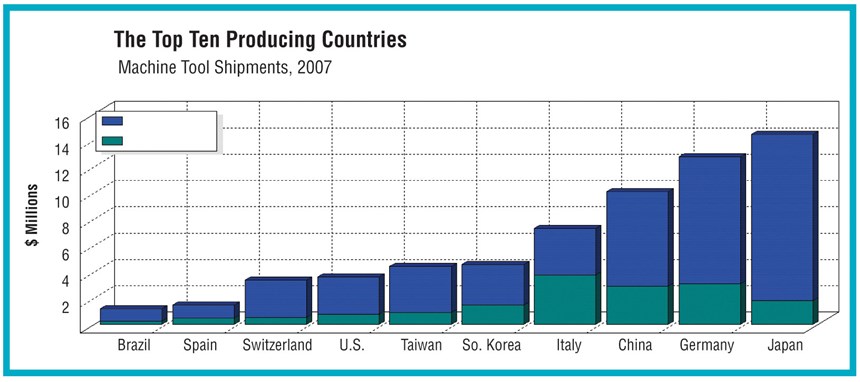

Turning to the other side of our annual “World Machine Tool Output & Consumption Survey,” that is, the production side, global output increased to $70,986 million in 2007, a percentage gain similar to that seen on the consumption side. That $71 billion, incidentally, was split into about 73 percent metalcutting machine tools including lathes and machining centers and 27 percent metalforming machine tools, such as presses.

Japan continues to lead the world in shipments of new machines, with Germany a not-so-far-behind second (see “Top Producers” table).

Third-place producer, China, saw a tremendous surge in output last year as its domestic factories, which had been pressured by a ravenous local appetite, cranked up output more than 40 percent over the previous year. As Chinese demand was increasingly supplied by Chinese output, the country’s imports declined a bit in 2007, reversing a trend. But even if its imports are slowing, China remains the world’s largest machine tool importer, ahead of the United States and Germany.

Among the other top ten producers, notable gains were made by Italy, Germany and Taiwan. Moreover, because of exchange rate shifts, the gains made by euro-denominated currencies were further magnified after converting to U.S. dollars. The ranking order of the top ten producers remained unchanged this year, with the exception that Brazil moved ahead of France.

Joe Jablonowski is editor of Gardner Publications’ “Metalworking Insiders’ Report” newsletter. For more information, go to www.metalworkinginsider.info.

.jpg;maxWidth=970;quality=90)

.jpg;maxWidth=970;quality=90)