Integrated Solutions for Chip Removal and Fluid Filtration

Shops can easily view chips simply as waste, hardly giving a second thought to the disposal process and the potential related savings. By keeping an eye on the waste and choosing the most efficient methods of chip disposal, a shop can easily add to the bottom line through substantial savings.

#metalworkingfluids #workforcedevelopment

Shops can easily view chips simply as waste, hardly giving a second thought to the disposal process and the potential related savings. After all, it’s the parts that are known to bring the profit. If everything’s running smoothly, there are more chips, more parts being produced and more profit being generated. But by keeping an eye on the waste as well, and choosing the most efficient methods of chip disposal, a shop can easily add to the bottom line through substantial savings.

The same story can be told for fluids used in everyday machining processes and, frankly, those involved in the shop floor maintenance processes as well. Without fluid management systems in place, even mop-and-bucket water from scrubbing floors can create disposal problems.

Featured Content

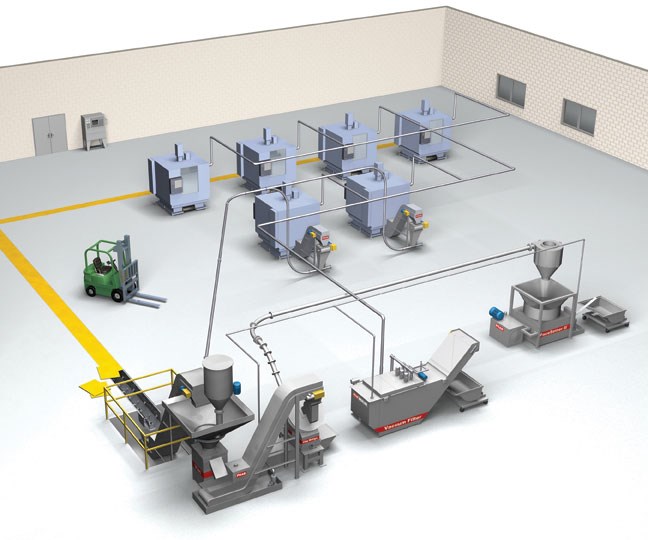

Even if a shop is handling one of these processes well, there’s a good chance it is overlooking the potential with the other. Prab now offers an integrated, modular solution that allows a shop to start small, addressing one or both of these areas, and seamlessly build a system that fully manages this non-glamorous end of the machining business. According to Mike Hill, vice president—sales, because of the company’s recent addition of the Monlan line of filtration and fluids clarification equipment, the company can now offer a variety of solutions to move chips, modify their size and shape, remove the fluid, and increase the value of the scrap in an environmentally conscious way.

“We’re taking this approach so that the smaller companies that have not positioned themselves to be able to have a full-blown chip processing system can now look at products that we have available in modular format, and as they grow, can just add to that system and keep tying it together without it looking like a cobbled up mess,” explains Mr. Hill.

Modular technology allows companies of any size to reduce the cost of capacity increases and allows machining operations to be more easily reconfigured as needs change. “We’re not going to see as many really large plants being built in the future,” says Tim Hanna, division president of Prab/Monlan. “There are not going to be as many of those entrenched conveyors, large centralized chip collection points and fluid management galleys. The smaller shops will need to be flexible with a system that can grow with them. This is an evolution in the way metalworking facilities will manage their metal scrap waste stream.” Many of these shops currently have no chip and fluid management systems and, instead, load the chips into portable bins that are hauled away to recycling centers as hazardous waste. But to gain control of costs, a company needs to seek ways to add value in every area, including chip and fluid management.

A typical starting point for a smaller company might be with the MiniSystem (Prab’s smallest single unit), a self-contained chip processing system that comes completely wired in a 4×11-foot footprint. It includes an infeed conveyor, a shredder and a chip wringer. Mr. Hill says, “We’ve had companies that didn’t have room in the shop for this system that have put it into a shipping container outside and used it from there.” Depending on a shop’s needs, the unit can operate on its own or it can be combined with other systems, taking the fluids removed from the chips by the wringer straight into a filtration unit. “That’s a good next step for growing the system,” explains Mr. Hill. “If a shop is using a simple, inexpensive water-based coolant and only needs to get the chips clean and dry to receive more value for them, this unit can handle it. Or a filtration unit can be added to take it to the next step.” The company offers an extensive line of fluid conditioning systems that will allow a shop to process fluids to whatever clarification level they choose, down to one micron.

Through fluid recycling, a shop can eliminate the problems that occur when tramp oils and suspended solids are allowed to accumulate in coolant or washwater systems, such as decreased tool life and machine downtime. An effective fluid management system can reduce new fluid purchases by 45–90 percent and reduce waste fluid volumes by 50–90 percent while helping to ensure compliance with federal RCRA requirements and state and local discharge regulations.

Ned Thompson, Prab CEO, stresses the significance of the range of products available. “We can now offer complete, turnkey solutions for all chip and fluid management needs, including system design, installation and ongoing support,” he explains. “In the past, we have had customers use our chip handling equipment, then use three or four other suppliers to obtain fluid processing equipment. Now it can all be obtained through one source, with one installation.”

Whatever the size of the facility, a review of the monthly costs involved with removal of polluted scrap containers and related housekeeping costs may be in order. Cutting fluids and lubricants used in metal production can be recaptured, accumulated and processed, resulting in clean recyclable metal (with enhanced market value) while allowing the re-use of once wasted cutting fluids.

RELATED CONTENT

-

Re-Turning Adds Life to Train Wheels

Unique turning considerations and circumstances come into play when re-turning well-worn freight and metro rail wheels.

-

Metalworking Vacuum Cleaners: One Type Does Not Fit All

As the metalworking industry becomes more specialized, so does the equipment that cleans it. But as diverse as the industry is, it should come as no surprise that there is no single vacuum that can handle all of its requirements.

-

Job Shop Automation: Fast, Simple and Agile

When done right, automation can provide important benefits. Here’s a look at automation options to suit the varying needs of typical job shops.