In the precision machining industry, lasers have not played a prominent role beyond part marking and engraving, but they have been added to Swiss-type lathes to cut tube material primarily for medical applications. Lasers have been useful for creating small holes and generating slots, spirals, helical shapes, widows and other complex geometries in cannulated stock on those machines.

Now, new technology uses a laser to act as a cutting tool to "turn" parts from solid barstock. This process, developed by the German company, GFH GmbH, replaces the conventional turning tool with a contactless laser that evaporates the material with ultrashort laser pulses while using less energy than traditional turning methods. The GL.smart high-speed precision turning machine, available to U.S. customers through GFH in Germany, is especially useful for micromachining, enabling high accuracy for small, complex parts that are often delicate and difficult to machine when implementing conventional turning processes.

Featured Content

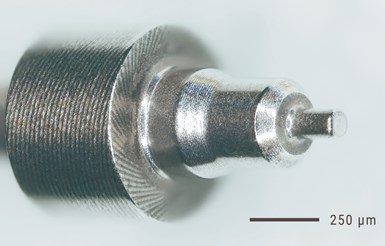

“Thanks to non-contact material removal, the workpiece remains free of force and deformation during the entire machining process,” explains Florian Lendner, CEO of GFH. “This means there is no loss of accuracy, even with very thin and delicate components.”

The machine also splits the beam from one laser source and delivers it into two separate heads, so it can turn as well as mill, drill and engrave two parts at once. Structure-wise, picture a dual-spindle, dual-pallet vertical milling machine with each station capable of turning and five-axis machining.

Contactless Processing

The heart of the machine is a diode-pumped, solid-state laser delivering pulses in picoseconds or femtoseconds on the workpiece. This “pulse on-demand” technique enables the adjustment of heat input on the material, making the workpiece less likely to overheat. As a result, no tension or part

The use of a high-power laser in combination with beam splitting enables simultaneous processing on two stations. Photo credits: GFH GmbH

deformation occurs. The company says this process is well suited for components made from both very hard and brittle materials.

Although the diode-pumped laser is the standard laser on the GL.smart, depending on the customer’s needs, GFH can provide different types of laser sources differing in wavelength, laser power or pulse width. Using these ultrafast and ultrashort laser pulses, as much material as possible is removed by roughing. When finishing a part, the final quality is achieved with lower laser energy.

The laser beam can be directed at the middle of the part or tangentially, depending on the operation. For example, if the component has a fixed diameter to be turned, the laser beam hits the material tangentially. However, if only certain areas are being machined across the entire diameter, such as holes, the laser beam hits the midpoint of the material.

The range of depths of material the laser can turn/remove in one pass depends on the material and the turning process itself. With tangential removal, the range from finishing to roughing is 1 micron to 200 microns, and with the laser beam directed at the middle, the range is 0.1 micron to 10 microns (finishing to roughing).

After machining, finished parts are handled and collected by either being manually taken out of the clamping system by the operator or by parts falling into a container below the machining area. To remove eroded material from the machine, the GL.smart is equipped with a suction system for collecting aerosols and dust.

“Smart” Capabilities

Machine shops that supply to the medical and watch industries will especially benefit from GL.smart’s micromachining capabilities, according to GFH. For example, the machine can produce microtools such as tweezers, microblades and implants as well as pivots that are installed in clockwork, the company says.

With the ability to machine virtually any material, the laser turning machine performs turning, drilling, cutting and engraving operations with high speed and precision, the company says. The machine also offers combination machining

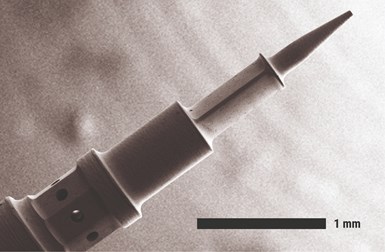

The GL.smart’s capabilities are diverse and range from medical microtools such as tweezers and microblades as well as pivots that are installed in clockwork.

as well as parallel processing on two C-axis workholding stations simultaneously, which doubles productivity.

Because of five-axis movement, all operations can be performed in one setup. Therefore, the workpiece can be engraved, cut, drilled or structured without any reclamping.

The air-bearing main workpiece spindles feature a torque drive that can be used to index/position parts and rotate up to 3,500 rpm in 0.4 second. Radial and axial concentricity in nanometers enable production with grinding tolerances. The machine also provides a force-controlled tension collet system. GL.smart’s compact footprint of 2,212 mm (L) × 1,026 mm (W) × 2,320 mm (H) is contained in a black glass housing that provides protection from laser radiation.

The machine is available with up to 16 simultaneous axes, controlled by its own developed system, GL.control. Each working station (Z-axis is the same for both working stations; Y-axis is separate for each working station) can be equipped with a main spindle (X- and A-axis) and a rotary unit (X-, B- and C-axis). The three axes remaining are placed in the optic box for beam manipulation.

CNC Controls Laser’s Precision

Programmed and controlled using its GL.control software developed by GFH, the machine’s computer numerical control (CNC) consists of one computer that is solely responsible for the numerical control software and another unit that is responsible for the operating software. The CNC integrates the CAD/CAM functions as well as all its subsystems. The GL.smart’s fast programmable logic controller (PLC) is designed for laser processing and offers real-time access for laser control so the laser can be switched on with an accuracy of 40 nanometers at the full range of axes movement.

The process for creating a cutting CAD/CAM program for a part includes:

- Uploading the 3D file to the machine’s software

- Selecting all geometries to be generated

- Generating the G code for laser machining

- Editing material-specific parameters

- Uploading to PLC

- Starting the machining job

When setting up the laser turning machine for a new type of part to be machined, it can be simple or somewhat more complex, depending on the size of the raw material, according to Lendner. “If the raw material is the same size, it only takes a change of software settings to create a new design,” he says. “If it is a new type of raw material size, the optical setup and clamping system must also be changed.” The machine accepts raw material of up to 12-mm diameter and length up to 2 m.

Building a Custom Machine

GFH offers numerous add-ons and accessories for the GL.smart that help users build a custom machine for their specific applications. Options include accessories for automation, monitoring and quality assurance.

The laser turning machine GL.smart provides non-contact removal. This means there is no loss of accuracy even with very thin and delicate components.

Because of the growing popularity and often necessity of machine shop automation, an addition of a six-axis robot workpiece handling system and bar feeder for the GL.smart is available. Implementing this option provides opportunities for lights-out machining as well.

Other options for the laser turning machine include a rotating swivel unit as a counterspindle and either a short or long turning design, or both. The setup of the collet and part guide define whether the machine has a short or long turning design.

GFH offers the following equipment as options for the GL.smart that are easily programmed through the GL.control.

Low-vibration laser beam: The GL.beam includes the complete beam path from the laser to the process optics within the machine. The laser is mounted and aligned on a granite base in accordance with the manufacturer’s specifications for low-vibration operation.

Precision clamping system: For repeated component clamping, the machine can be equipped with GL.clamp, a precision clamping system from Erowa. On request, clamping systems from other manufacturers or vacuum clamping devices are also available.

Monitoring and beam adjustment modes: The laser systems can be extended by the operating modes GL.om3 and GL.om4. Operating mode 3 is used for process monitoring, and operating mode 4 is for beam adjustment.

Scanner system: For precise production of parts or deep engraving, the machine can be equipped with a scanner system called GL.scan. It positions the laser beam on the workpieces via two galvo mirrors.

Optical measuring system: The optical measuring system, GL.vision, facilitates the positioning of the component under the laser and also offers the possibility of optical measurement with the resolution of a microscope.

Fixed optics module: The GL.optifix module provides fixed optics for laser drilling, precision cutting and ablation. There are no moving components in the optics, thus reducing the positioning error to the precision of the axis system.

Distance module: The GL.distance module is available for the highest precision requirements for micro-drilling and precision cutting. Deviations and tolerances of the component surface can be recorded and corrected before machining.

GFH GmbH | gfh-gmbh.de/en/

RELATED CONTENT

-

Manufacturing Efficiently at a Micron Level

Grinding very small-diameter instruments for use in medical procedures is a niche business for this micro-grinding machine manufacturer. The company makes machines that use a variety of grinding techniques to manufacture guidewires for the medical industry.

-

Making Micro Threads

Production of micro threads can be challenging, but using the most suitable tools for a given application can simplify the task.

-

Micro Deburring Gets Hot

“Micro deburring,” a name commonly used to describe the deburring of tiny small parts, is often considered more of an art than a science. Although this is true to some extent, deburring micro parts does not always have to require hand manicuring parts with a scalpel under 10× to 20× magnification.