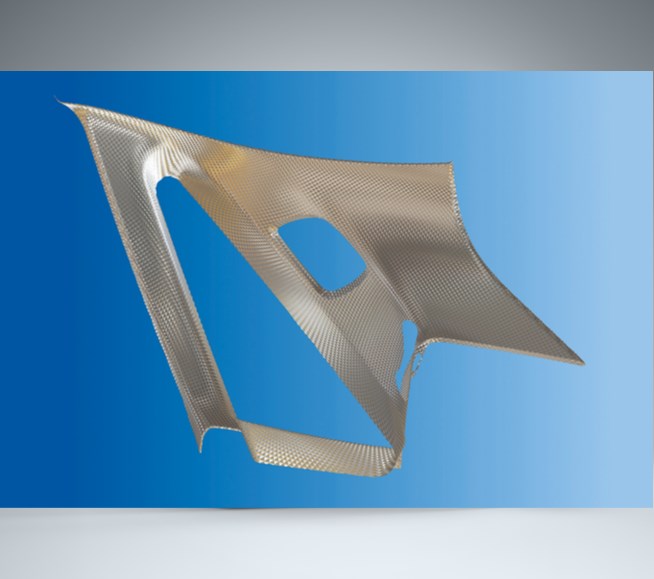

Chemical etching has become something of a default for processing injection molding tools used to produce interior trim pieces. The etching provides the patterns that make the surfaces of those parts look more appealing (and less like, well, plastic). However, this is giving way to another process, laser ablation.

Using laser systems seems to be superior to chemical etching in almost every way: Where chemical etching process is labor-intensive—the tool must be cleaned, masked and sandblasted before the acid can be applied—the laser system requires minimal human intervention before and during the process.

Featured Content

Acid-etched textures are also traditionally hard to keep consistent from mold to mold because of the inexact nature of the process. That means it can be hard to get an exact match between the textures of adjacent parts made with different molds. Lased textures in contrast are digitally controlled and infinitely repeatable.

And working with caustic, environmentally unfriendly chemicals provides its own suite of challenges, from handling to disposal.

The one metric that chemical etching owns, however, is speed. A laser removing a pinprick width of material at a time simply can’t match the metal removal rate that comes from exposing the entire surface of a well-prepped tool to acid.

Two new laser systems have been designed to speed up the texturing process to a rate that, combined with those other advantages, may lower the cost per part enough to make them a worthwhile replacement for chemical etching.

Laser S

One of the ways of increasing throughput in laser ablation is determining where the laser head should be positioned throughout the texturing process, so the five-axis AgieCharmilles Laser S series from GF Machining Solutions (gfms.com) performs 3D scanning of the surface of the tool at a rate of up to 5, 500 mm per second, then the system’s Smartpatch software module analyzes the scan and generates an optimal cutting strategy for a desired texture.

Another time-saver is a portfolio of lenses that allow the laser to ablate a greater area before the laser head needs to physically move. The marking area can be up to 66 percent larger than on previous GF systems. These lenses enable the laser head to be further away from the surface of the part as it cuts, which means even deep cavities can be textured.

The laser head can optionally be fitted with twin lasers of different strength for more flexibility. For example, a 100-watt laser—which allows about 30-percent faster material removal than a 50-watt source—can be twinned with a 30- or 50-watt FlexiPulse laser. The user can manipulate the pulse duration of the latter to find the best balance between surface finish and material removal rate on certain applications.

To achieve better thermal stabilization of the laser the monobloc design of the laser head ensures a consistent temperature throughout the tool, and two water-cooling circuits regulate thermal changes in the laser head to ensure consistently high precision. The temperature within the head is kept within ±1° C.

The system also saves time by enabling a variety of tasks—such as laser blasting, structuring, machining and marking—as well as texturing in a single setup.

The eVerest Project

While the Laser S system is commercially available right now, the eVerest project is being undertaken by an industry-university partnership funded by the German Federal Ministry of Education and Research.

The objective of this research project is to make a system that would be characterized by speed and quality, according to Andreas Brenner of project partner Fraunhofer Institute for Laser Technology ILT (ilt.fraunhofer.de/en.html).

The researchers started with an eight-axis DMG Mori Lasertec 125 and then added software and hardware so that the system has up to three times the throughput of earlier systems, according to Brenner.

Faster scanning is one improvement. The partnership improved the algorithms used to scan the tool surface, reducing the amount of unproductive “dead time” in the scan paths. This was made possible not only by revisiting the scanning software but by developing a new dynamic focusing system based on the use of convex piezo mirrors.

This system goes far to maximize its ablation rate without sacrificing accuracy. It includes both a standard nanosecond laser and an ultrashort pulse (USP) laser, which provides nanometer-level precision but traditionally ablates at a much lower rate. So they selected a laser from partner and Trumpf subsidiary Amphos GmbH, an actively cooled USP laser that can reduce surface roughness to less than 0.5 µm at the same ablation rate per watt as the nanosecond laser.

Making the entire system easy to operate, without requiring any specialist expertise in the technologies used, was another objective. So software tools were developed that allow the user to easily simulate surface texturing and visualize their appearance in real time. The control system makes it possible (as on GF’s Laser S) to quickly set up a succession of laser processes in a single clamping. And the number of processes requiring operator attention have been reduced to a minimum. After all, “the simplicity of the processes represents one of the main advantages over etching, which frequently still relies on the instincts and dexterity of the machine operator,” notes Fraunhofer’s Brenner.