The introduction of high-power, square-pole, electro-permanent magnetic milling chucks to the North American market occured at IMTS 1994. At that time, conventional wisdom was that magnets were for grinders—relatively low power magnets holding a flat plate against stops. The grinding wheel created down force and the stops prevented sliding—everything worked great.

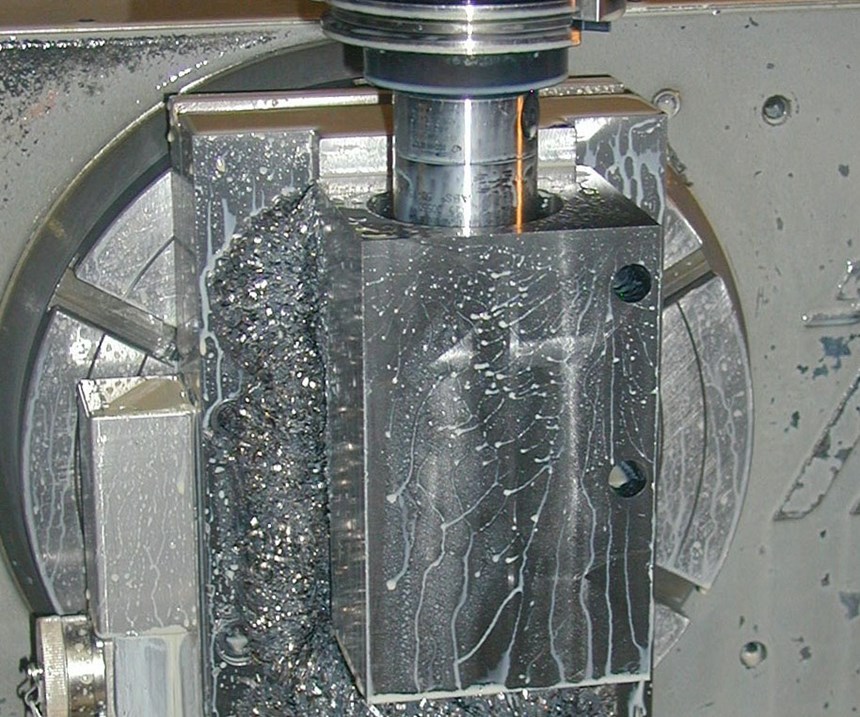

However, a demo at that show that stopped people in their tracks was a round bar on a magnet—the bar was rolled against a side rail, giving line contact in Y and Z axes. Otherwise, the bar didn’t move.

Featured Content

In came a face mill to take an aggressive cut; chips went flying and the bar stayed put. The cut finished, the magnet switched off, the chips all blew clear, and the part was released. Magic!

Twenty-four years later, the electro-permanent magnetic chuck has become more compact, more efficient and an established workholding method for milling and turning. For mild steel, the chucks typically achieve more than 200 psi clamping force over the magnetic poles. For a 20-inch by 40-inch chuck covered by a mild steel plate, the clamping force is more than 80,000 pounds.

Smaller production parts, however, present more of a challenge since contact areas and holding forces are smaller. However, the modularity and flexibility of magnets offer possibilities to effectively locate and clamp production parts and can also offer flexibility to accommodate families of parts.

Magnetic Advantages

Five-axis machining drives the need to hold workpieces with as much access to the five sides that the machine can reach. To achieve this, a clamping method that holds from one face only is required.

By definition, clamps and vises grip across the part, which eliminates access to the “bottom” face and compromises access to the two contact faces—the best possible access is three complete faces, plus part of two more. Magnets allow parts to be gripped from one face, leaving five of the faces completely free.

Fragile parts also can often be held magnetically when use of clamps or vises cause distortion. Since the magnetic grip is formed across the interface between part and magnet, there is no tendency to crush a fragile part.

Square-pole magnet designs provide an excellent platform for tooling. These steel blocks can be organized to create clamping faces to match the needs of the part. Magnetism flows from north to south poles and can create grip in X and Y axes as well as Z, or any combination thereof.

It is entirely possible to clamp prismatic parts on two or three faces, and it is also possible to arrange a sequential firing sequence, for example, clamp sideways and then down to ensure that a rail is positively located and pulled straight.

Electro-Permanent Magnet Circuit

The basic high performance electro-permanent magnet circuit is the double magnet (DM) system. The DM circuit comprises of a steel case in which a series of steel pole pieces (typically square) are mounted. Under each pole is a coil surrounding a permanent magnet that can be reverse-magnetized by the coil. The material used (typically AlNiCo—aluminum, nickel and cobalt) has good magnetic performance, but is relatively easy to magnetize, reverse-magnetize and demagnetize. Surrounding the steel pole pieces are a second set of magnets that do not switch—typical material is a neodymium rare-earth element that has good magnetic performance and is virtually impossible to reverse-magnetize or demagnetize.

To switch on the magnetic circuit, the AlNiCo magnets are energized in the same orientation as the non-switchable rare-earth magnets. The rare earths with north polarity against the sides of the steel pole are combined with AlNiCo with north polarity against the base of the steel pole, and the steel pole becomes a north pole.

To switch off the magnetic circuit, the AlNiCo needs to be reversed magnetized to present a south polarity against the base of the steel pole. If the two sets of magnets are “matched” to be equal, then all of the north polarity energy of the rare-earths is absorbed by the south polarity of the AlNiCo and the working face becomes non-magnetic.

This design is able to saturate the workpiece with maximum clamping force. The on/off switching is fast—less than 1 second. Power is consumed only during the switching phase. Once magnetized, the device stays magnetized until switched off.

Holding Force

With magnetic workholding, the workpiece forms half of the magnetic circuit. The magnetic chuck is the engine, but the part is what closes the magnetic circuit and creates the clamping force.

However, different materials have different magnetic saturation levels, resulting in different maximum holding forces. For mild steel, ultimate pull force potential is about 210 to 220 psi. For alloy steel and soft tool steel, the holding force must be reduced by about 20 percent, and for hard tool steels and cast irons, by about 40 to 50 percent.

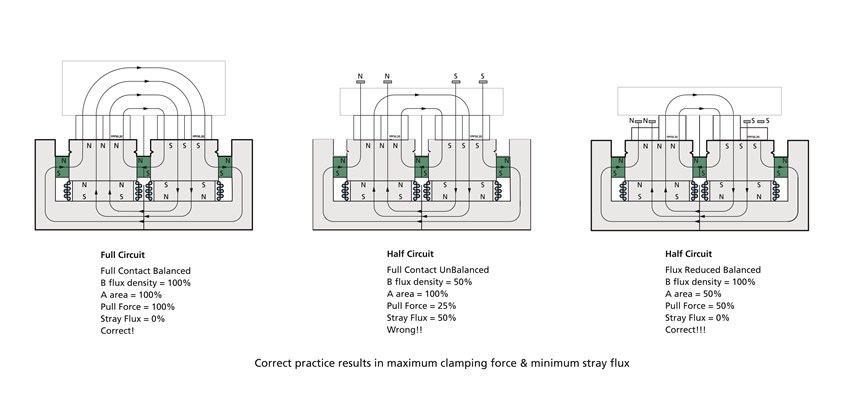

Therefore, the workpiece can become a “choke point,” limiting magnetic flux flow (part is too thin to transfer full magnetic flux from north to south poles). Or if the magnetic circuit is unbalanced (contact area with north polarity poles doesn’t equal contact with south polarity poles), then flux density at the contact faces will be sub-optimal, and the part will become magnetic.

Conversely, when correctly organized, a part being held on a magnet will be non-magnetic, and the chips will fly free. Often, this optimization involves reducing or manipulating contact area—counterintuitive, but true.

Top Tooling

Standard square pole chucks typically have tapped holes in the center of each magnetic pole for the attachment of “top tooling.” These are mild steel blocks that lift the part off the magnet face and provide positioning references that can manipulate the magnetic flux flow for optimal part clamping.

There are a variety of top tooling configurations that can be used to achieve optimum balanced flux balance and contact. Figures 1, 2 and 3 show examples of three types of top tooling in applications.

Square-pole electro-permanent milling magnets offer exceptional possibilities for holding production parts. Simple top tooling allows the magnetism to be brought to the part even when the part is complex and can offer flexibility for families of parts with minimal change-over.

Properly configured, the part will be non-magnetic and should fly free of the workpiece. For security, if there is a power failure, the part will stay put. The magnetic workholder is autonomous because the cable does not need to stay attached to pallets or indexers. For many applications, magnetics can be another arrow in the shop’s workholding quiver.

About the Author

John Powell, Ph.D.

Dr. Powell is the president and CEO of WEN Technology Inc.

RELATED CONTENT

-

Making Micro Threads

Production of micro threads can be challenging, but using the most suitable tools for a given application can simplify the task.

-

Understanding CNC Collet Chucks

Workholding for turning is usually fairly basic: The selection comes down to chucks or collets. This article looks at when to consider the collet chuck and what kind might be best for a given application.

-

Bar Feeder Basics

Some primary factors are often overlooked when considering how to justify the implementation of a bar feeder for turning operations.