Methods Machine Tools Partnership

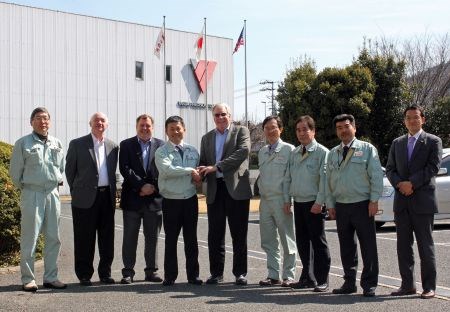

Methods Machine Tools Inc. has signed an agreement to represent Yasda Precision Tools across the U.S.

Methods Machine Tools Inc. has signed an agreement to represent Yasda Precision Tools across the U.S. Yasda is a Japanese builder of machining centers and jig borers with a reputation for accuracy, precision and quality.

Featured Content

“We are very pleased to announce this partnership,” said Mr. Bryon Deysher, president and CEO of Methods Machine Tools, Inc. “Yasda Precision is a perfect complement to our high performance machining solutions. With meticulously hand-scraped surfaces and superior machine construction, Yasda’s extremely high precision stands alone. We are now proud to offer the pinnacle of quality and precision in the machine tool industry.”

“We are pleased to have Methods representation. Their extensive distribution infrastructure, applications expertise and network of technology centers will help significantly expand our brand and capabilities in North America,” said Mr. Takuto Yasuda, president of Yasda Precision Tools. “We are excited about the agreement and are looking forward to a long and mutually successful partnership. We also look forward to working with Methods on new product development for the U.S. market.”

Yasda Precision uses only Yasda machines to build their own machine tools. The machine tools are designed for applications where ultra-high performance, accuracy and rigidity are paramount. Methods will be offering the complete line of Yasda machines.

- Yasda Precision offers vertical, horizontal and five-axis machining centers, all capable of jig borer accuracies. Many platforms are available with multiple pallet configurations for lights-out manufacturing.

- Yasda specializes in die mold machining solutions for automotive, aerospace, medical and high precision electronic and optical components. The accuracy and rigidity of the platforms are designed to virtually eliminate the need for hand polishing.

- The thermal stability and structural integrity of Yasda four and five-axis machines make them well suited for today’s demanding nickel-based alloys, stainless steel and titanium machining requirements in the aerospace, oil field, power generation and medical industries.

- High speed linear motor ultra-precision platforms are also available to serve all intricate tolerance, small part applications.

Select machines are slated to be installed for demonstration at Methods technology centers in the near future. Yasda and Methods will also be providing the necessary technical resources, applications and service to support the expansion of Yasda machines into the U.S. market.

RELATED CONTENT

-

Understanding CNC Collet Chucks

Workholding for turning is usually fairly basic: The selection comes down to chucks or collets. This article looks at when to consider the collet chuck and what kind might be best for a given application.

-

Hard Turning as an Alternative to Grinding

Hard turning can be a cost effective alternative for shops looking to streamline part processing.

-

A New Approach to CNC Turning

This turning process takes advantage of a turn-mill’s B-axis spindle to vary a tool’s approach angle to optimize chip control and feed rates.

.jpg;maxWidth=970;quality=90)