Millennial Multitasking Made Easy

CNC control software is being designed with features to better fit the tendencies of younger operators.

Machine tool controls are much different today than even 10 years ago, when operators needed to have a background knowledge of G-code programming to feel comfortable when navigating a CNC control. But thanks to new software programming technology from Nakamura-Tome, visual-minded, icon-oriented operators who are unschooled in G code can easily operate complex machine tools such as multitasking turning centers. This approach is especially advantageous for shops hiring young operators who may lack the experience and knowledge on CNC machining, but are comfortable with intuitively designed, icon-rich software programs.

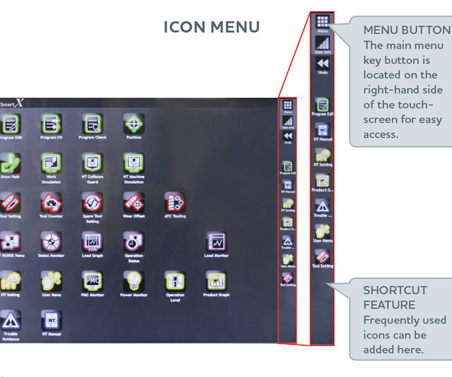

Nakamura-Tome has introduced a “Smart X” operating system for its PC-based control that includes a FANUC 31I-A5, five-axis control. This control includes many new Nakamura features such as an icon menu, production monitoring, trouble guidance and an operation-level control function. The main control has a 19-inch LCD touchscreen with Projected Capacitive Touch (PCT), similar to an iPad. The control runs on Microsoft Windows 8.1, with an icon-driven menu for easy access to many different screen views, including a special hot button feature that allows operators to customize the display to their preferences. This feature works like an icon on an iPad, so operators can be comfortable quickly moving from different displays and can only display what is important to them. These features are designed to make younger operators feel more comfortable with the machine control.

Featured Content

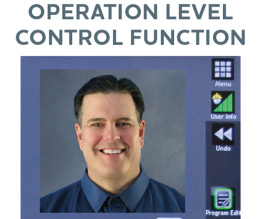

With an operation-level control function, an operator can log into the control as he/she would on a PC, with name and password, but the operator is assigned a level of operation by management. The level will only allow access to features of the machine control for which the operator has been trained. The level can change as his or her capabilities advance. Companies can utilize five different levels, from the basic level of cycle start and override switch and chuck open/close, to the top level, allowing full permission to review PMC parameters, macro links and program edits.

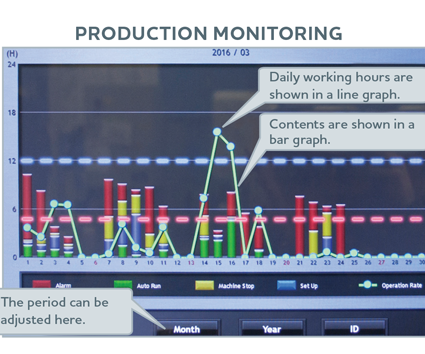

This operation level also links to the production monitoring system, which shows who was operating the machine during a particular time or day. The production monitoring feature allows a user to review the production capacity of the machine tool hourly, daily, weekly, monthly or yearly. Part numbers can also be looked up, and users can see the efficiency of the day’s production. The results can be downloaded to a PC, and they display when the machine is in an alarm mode or setup mode.

A trouble guidance feature helps the operator clear an alarm state via a step-by-step pictorial on the control LCD. It will even give the part number that may be needed to resolve the issue. Users also get a history of any alarm, with dates and number of repeat alarms. Warning messages are recorded as well.

Nakamura has also designed a number of features to help simplify the operation of a multitasking machine. The cut-in-check feature allows the operator to stop the process with a push of a button. When the button is pushed, the machine stops at the end of the next program line, the spindle stops, coolant stops, and the safety door switch opens. An operator can then check a size, inspect a tool or remove chips. When finished, the operator can simply push the cut-in-check button and cycle start to resume the process. This feature can be valuable to the operator when running a complex process.

Many other display features show the machine status. Most are shown in several different ways. The main status display shows spindle rotation and axis home position as an illuminated indicator; feed rate override and load meter are shown with a graphic or numerical display. A voice guidance feature will speak to the operator to verify the status of the switch or button being used. Voice guidance provides an additional check to prevent operator error.

The Smart X control includes more features incorporated into the advanced levels, designed to make machine tool operation more intuitive for the millennial user.

RELATED CONTENT

-

When a CNC Turn-Mill Doesn’t Turn

A shop in Big Sky Country uses a B-axis multitasking machine to produce complex, prismatic medical parts that require no turning complete from barstock.

-

How Advancements in CNC Multi-Spindles Can Put You Ahead of Current Trends

Growing economic and labor pressures are making CNC multi-spindle turn/mill technology more viable than ever. This real-world comparison to a single-spindle lathe shows how.

-

Choosing the Right Machine for Turned and Milled Medical Parts

The medical market is known for exceptionally tight tolerances and difficult materials, which means that selecting the proper machine is necessary to ensure a job is profitable.