For companies to stand out from their competitors, they need to be lean manufacturers and believe in excellent customer service. These characteristics describe Innovative Precision Manufacturing (IPM) in Concord, Calif., a full service CNC machine shop 30 minutes east of San Francisco. The company’s owners use forward thinking to carry out their business plan, and that thinking has guided them through opening the machine shop during the recession, in July 2010.

Pinpointing the problems affecting manufacturing and having a dream and a vision of running a business that doesn’t have these problems has been the guiding light for the company. “We saw other shops suffering by making promises they couldn’t keep, for example, having impossible lead times and not checking parts,” says Alex Cartwright, president and founder. Another problem with many shops, he says, is that the customers are calling the shops to see how their parts are coming, when it should be the other way around.

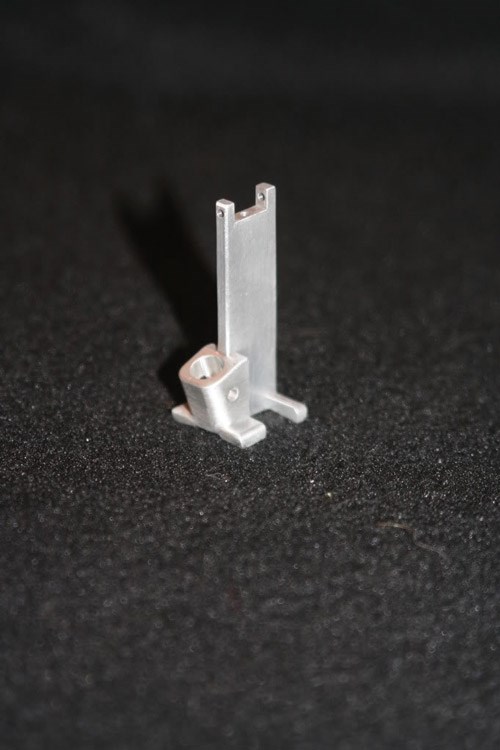

IPM produces precision machined components for the medical, aerospace, defense, semi-conductor, specialty automotive and oil industries in its 6,000-square-foot facility and has six key clients. With all of its capabilities, including the use of the latest CAD/CAM software, 3D modeling systems and its own quality control department, Mr. Cartwright says the company is set up similarly to a massive company, even though it is not one yet. The owners do this so IPM can grow into its equipment and facility at its own pace.

Believing in steady growth is one of the company’s philosophies that keep it focused. “We have turned away some work on the things that would force us to grow big too quickly,” Mr. Cartwright says. “One problem I see with some shops is that they grow too fast and take on too much overhead.”

To keep costs under control, Mr. Cartwright and his partner, Nick Peterson, purchased some equipment from an existing shop, but also bought new equipment prior to its opening. The shop is set up for part runs from 100 to 10,000, using CNC mill/lathe capabilities with tolerances down to 0.0001 of an inch, mill-turn machines, fourth-axis capabilities on a mill-turn center and a full manual department for prototype work.

Starting a machine shop requires knowledge from various pools, which is why it works out well that the partners (and friends) have different educational backgrounds, but are working together toward the same goal. Mr. Cartwright was an international business major who became an English teacher in Taiwan. “I got first-hand knowledge of production machining in Taiwan and mainland China,” he says. Later, he worked on various business models, implementing key solutions and revitalizing problematic companies in the states. Mr. Peterson, on the other hand, began working in a machine shop at age 15, so he has the most hands-on experience.

Because of their intuitiveness, the IPM partners are living their dream by following through with customer needs and going above and beyond customer expectations. They start by simply doing everything they say they are going to do and communicating with customers. Mr. Cartwright says, “We have great customer service; customers are always welcome in our facility. We are very proactive in the design element; if we change or modify one aspect of a part, we let customers know we can save them some money doing it a different way. We are thorough about communication with our customers and parts development.” Parts are thoroughly inspected at IPM, which can only result in quality parts and customer satisfaction.

Staying current with the latest technology is also a priority for the shop. “Being a younger shop with younger guys, technology is our forte,” Mr. Cartwright says. “The (old-school) mindset of ‘this is the way it is done and always will be’ is how American shops lose a lot of business to China. They don’t stay cutting edge.”

Although the shop’s opening has been successful, it has come with challenges as well. Name recognition is one obstacle, according to Mr. Cartwright. It is a struggle to earn customer trust when your shop isn’t well known yet.

Another obstacle, the poor talent pool of machinists, is dealt with by training people in-house at IPM. “Sometimes a machinist from elsewhere has learned bad habits,” Mr. Cartwright says. “We’ve had to train someone to run our swing shift, and that took about a year. It is a slow moving process.”

At the same time, the owners don’t want to hire too many machinists, especially all at once. “We see the downfall of machine shops—they get a couple of good orders, and they think these orders will stick around. They order more machines and hire more people, and then a few months later the orders are taken away from them,” he says. The company prides itself on lean manufacturing, operating with only eight employees.

Although it runs a small shop now, the IPM team has big aspirations. “We would like to turn the company into an in-house manufacturer—basically have our own brand/products,” Mr. Cartwright says. “We want to develop our own medical device business, do more in-house work and do more production machining rather than prototype work. We also would like to learn about other industries. There’s obviously money in other places besides the industries we service.”

Planning ahead and foreseeing future problems and opportunities is what the owners do best. With this forward thinking mindset as well as its excellent customer service, lean manufacturing and cutting edge technology, success is likely to come easier for this shop than other shops that do not follow these philosophies.