Precision Workholding Offers Multiple Advantages

As American manufacturing continues to transition from the mass production of conventional parts to the manufacture of complex, high-value components in relatively small lot sizes, precision workholding has assumed increased importance

#basics

Efficiency and throughput in precision machining operations continues to be the watchword for American metalworking manufacturers. Many shops have taken steps to accomplish these goals through higher performance machine tools, using automation, improved cutting tools, optimized programming techniques and more.

The net result has been a resurgence of globally competitive, home-grown metalworking. Those shops that have seen productivity improvements with better applied technology are looking to precision workholding solutions as another opportunity to move a competitive step forward.

Featured Content

In key manufacturing segments, conventional chucks are being replaced with high precision workholding units, offering improved construction, increased gripping power, improved repeatability, more flexibility, faster change-over and longer life. The driver for this, like most shopfloor technology improvements, is market demands for tighter tolerances, and more consistent quality and flexibility. While this general trend is true across most metalworking operations, it is especially true in the manufacture of parts of rotation. Increasingly, the advantages of precision workholding are being viewed as a critical component in overall manufacturing process.

“To compete effectively in today’s manufacturing environment, the machine, the workholding device and the cutting tool must all work together to optimize your return on investment,” says Jim Woods, president of Hainbuch America. “If any one of those elements is inferior, the whole process suffers. This interdependence is especially crucial when it comes to high precision components where tolerances are tight and pristine surface finishes are required.”

The changing nature of volume manufacturing is another critical factor in the move toward higher precision workholding in turned parts. No longer can a shop set a machine and run it for long periods of time.

Most of those jobs have become victims of shorter product life cycles, and in some cases, blanket production orders. The ability to quickly change from one workholding size, and in some cases, type (such as OD to ID), is also driving this move to precision workholding.

“Because valuable parts often need to be run in small to medium sized lots, the change-over from one part

to another has to be performed quickly without sacrificing any of the elements that could impact quality,” continues Mr. Woods. “It all about what we call ‘Your Green Light Strategy,’ which, on the shop floor, means working to maximize the time machines are producing at optimum cycle times, while producing a quality part with each cycle.”

Go to the Light

A demonstration of Green Light Strategy in action can be found at RFM Inc. of Brighton, Michigan. The company is a wholly-owned subsidiary of Mitsubishi Materials.

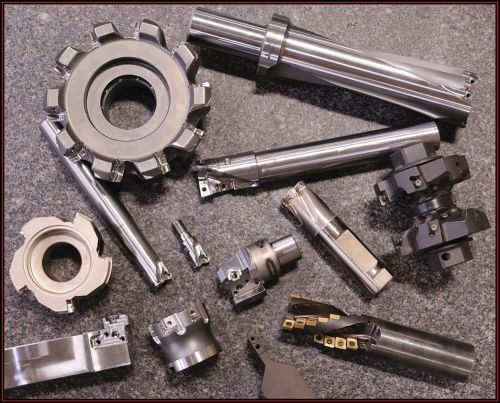

RFM manufactures high quality, indexable insert cutting tool bodies including shell mills and end mills. The manufacturing process uses multiple turning centers, including two Mori Seiki NL2500s and an Okuma LB3000MY lathe. All of these machines are equipped with a bar feeder.

“Prior to 2006, we used standard three-jaw chucks; but, as our tolerances tightened, and we looked for more efficiency in change-over, we realized we needed to find a better method,” says RFM’s plant manager, Tim Barnes. “We typically rough machine the body of our tools on the back end, then transfer the part to another lathe to machine the other end. The part is then sent out for heat treating and subsequently placed in a chuck with center drive for finishing operations. Unless your chucks are extremely accurate, moving workpieces between machines can cause real problems. This is especially true when the tolerances go from 0.005 inch in the roughing operation to 0.0003 to 0.0005 inch in finishing.”

Another factor demanding improved workholding capability is the material used. Although many parts are machined from 4-foot bars of 4140 and 4340 steel, special orders demand harder materials that require increased gripping power. Mr. Barnes says, “The chucks we now use employ a parallel clamping design that allows the engagement of 85 percent of the diameter—significantly more than a standard three-jaw chuck. That results in 25 percent more gripping power.”

A major reason to incorporate improved workholding is change-over time. “Our part runs vary widely,” Mr. Barnes says. “I would say our longest runs are from 400 to 500 pieces, but we frequently do lots as small as 5 to 10 units. When you calculate the dollar value of the time involved in change-overs with conventional chucks, you’re talking about a large financial burden.

“The quick-change feature enables us to load and lock different collet sizes quickly and easily without sacrificing quality and accuracy,” he continues. “In fact, we are now able to machine surfaces in-house that we used to have

to send out for grinding, and our change-over time is 35 to 40 percent faster.”

In his 22-year career at RFM, Mr. Barnes has progressed from the shop floor to his current position of plant manager, a transition that enables him to see the business from both a technical and a managerial standpoint. “Improving workholding capability, like any capital improvement, demands an investment of both time and money and has to justify itself,” he says. “Our shop produces roughly 2,800 parts per month, with a staff of 15 people. By improving our procedures, we’ve generated improved efficiency and increased our per-person output. As a result, even in slower times, we haven’t had to lay anyone off. When you consider what a company invests in each person in terms of training, that represents a significant achievement, along with the fact that we’ve been able to keep our corporate family together.”

He continues, “We’ve also added continuously to our output, and we expect to produce even more in the future. By adopting high precision, quick-change chucks, we’ve not only reduced scrap and improved change-over times, we’ve maintained and even improved the quality of the parts we make.”

Helping Shops Help Themselves

The need for support and training from the manufacturer is a critical factor in introducing improved workholding technology. It’s generally not a “plug and play” solution for precision manufacturers.

According to Larry McMillan, Great Lakes Area regional manager for Hainbuch America, “The adoption of high precision workholding technology is a major move for any manufacturer and involves significant responsibilities on our side. First, we need to survey the operation and look carefully at both the present parts mix and what is anticipated in the future before we recommend the appropriate chuck. These chucks have two basic configurations: one, called the Spanntop, uses a round collet clamping unit, and the second, called Toplus, uses a hexagonal clamping unit.”

The quick change comes from the use of a permanently mounted face plate attached to the spindle nose. In the case of Spantop, the receiver is round. For the Toplus, the receiver is hexagonal. These are precision taper connections for high accuracy.

From this base plate, various chucking units attach for ID clamping (using and expanding bushing), OD collet clamping or three-jaw OD clamping. All are actuated by the base plate unit, making change-over as short as 3 minutes. In addition, collets are available with smooth faces and serrated designs for improved gripping. Several grades carbide or diamond can be specified as well.

Both designs offer multiple features, and, where necessary, special order chucks can be made and customized to the individual application requirements. In applications involving highly polished parts or no-mar surface finish specifications, custom collets with plastic coating are available.

It’s important in today’s manufacturing environment that precision workholding emphasizes not only the speed of change-over, but the flexibility needed to convert from one setup to another, depending on an application. Since these are precision workholding devices, it’s essential that the shop’s processes be understood thoroughly prior to making a recommendation. In precision workholding, the unit must match the application, and the manufacturer must have the in-house capability to make that match work.

“The second phase of the evaluation involves installation and training,” Mr. McMillan says. “Precision workholders, such as Hainbuch’s, are both faster and easier to operate than conventional three-jaw chucks. They also have multiple features and much better versatility.

“It’s our job to make sure that the customer and the operators understand the scope of the advantages to get the most out of the product. Once the installation is complete, we maintain close touch to answer any questions or assist in any way we can. I tell our first-time buyers that we are at the beginning of a long relationship because our products have such an extended life. We installed the first chuck in RFM more than 12 years ago, and it’s still performing to specification.”

Taking the Plunge

RFM’s decision to opt for versatile, high precision workholding has delivered the expected benefits of improved efficiency, faster change-over and higher accuracy. As part blanks are roughed on one machine, heat treated, then finished on a second machine, the improvement in repeatability alone has been a big benefit to RFM.

Mr. Barnes notes a further advantage. “When you have confidence in the performance of your tools and the quality of your processes, you are not afraid to try new things. Our experience has proven to me that precision drives innovation.”

RELATED CONTENT

-

The Many Sides of Workholding

Here's a broad look at different ways to approach workholding, from bar feeders to collet chucks to robotics.

-

4 Strategies for Managing Chip Control

Having strategies in place for managing chips is an important part of protecting the production process, from tool life to product quality.

-

Making Micro Threads

Production of micro threads can be challenging, but using the most suitable tools for a given application can simplify the task.