Shop/Supplier Relationship is Critical to Success

A quartet of CNC machines supplied by T W Ward CNC Machinery Ltd. play a key role in enabling Cosmopolitan Engineering to consistently be a supplier of parts of all sizes and in all metals, including tool steels and titanium, for more than 30 years.

Precision sub-contract machinists like to keep contract details close to their chests. Whether it be singular specialty jobs or production schedules that continue for some time, many shops have work that the staff can’t talk about. Cosmopolitan Engineering (CE) is one of these shops.

The Sheffield, England-based company is involved in securing and processing contracts with workpieces to be used in high-profile manufacturing projects. The company’s accreditation to ISO 9001, the international standard specifying requirements for a quality management system, has resulted in a project list that includes precision one-offs for marksman’s guns, steam traction engine parts and nuclear project work the company isn’t allowed to discuss.

Featured Content

Mark Leonard, who has been the production manager at the company for more than two decades, thinks it’s a shame he can’t talk about certain projects. “The complexity of some of the final-build projects would really show how small, highly skilled engineering companies such as ours continue to play a crucial role in creating awe-inspiring engineering spectacles.”

Despite a lack of publicity on such work, CE has been a supplier of parts of all sizes and in all metals, including tool steels and titanium, for more than 30 years. This has been done with its portfolio of CNC machines to turn, mill, drill and grind workpieces, including a quartet of machines supplied by T W Ward CNC Machinery Ltd. (Ward CNC), that play a key role in enabling the company to consistently meet customer demands.

For shops such as CE, working closely with local suppliers such as Ward CNC is key. These kinds of partnerships can provide shops with access to unique processes only dealers can provide. For new jobs, a supplier knows the machines better than the customer. Eventually, a shop such as CE becomes familiar with the processes, but at first, the relationship with the supplier is key because of the CNC machines at its disposal.

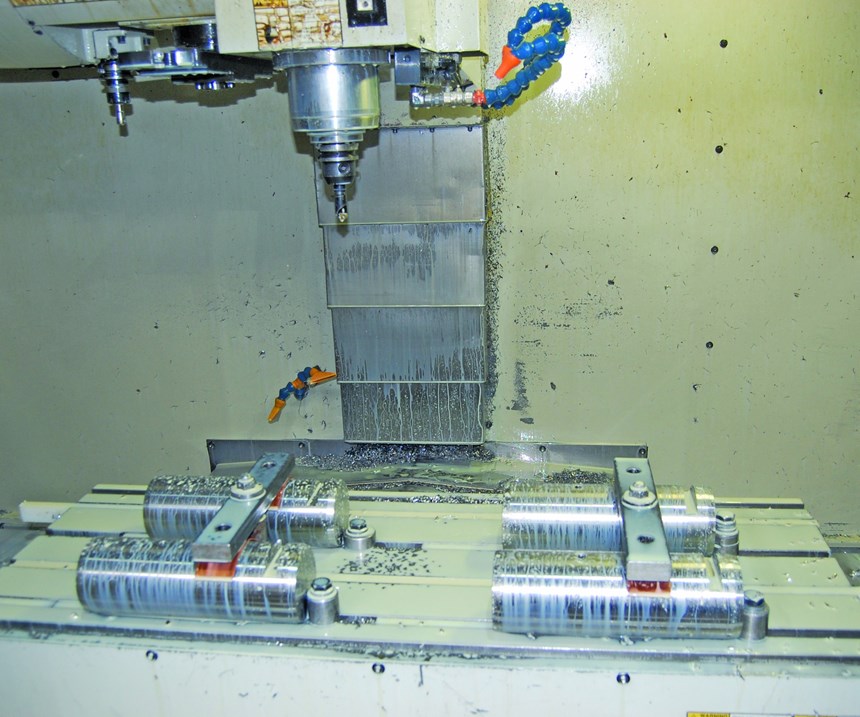

Those CNC machines include Hyundai-Wia machines such as the L400LMC lathe with a C axis and driven tools, with maximum turning diameter and length capacities of 22 inches and 83 inches; the SKT-300 turning center, with maximum turning diameter and length capacities of 22 inches and 28 inches; and a L300C two-axis lathe, with maximum turning diameter and length capacities of 20 inches and 28 inches. CE also owns a Hartford Omnis 1020 VMC that has XYZ capacities of 40 inches by 20 inches by 20 inches.

These turning machines have enabled the seven-employee firm to meet customer demands throughout the U.K. and across all industries. On the two larger parts, which are machined on the 2-meter bed L400LMC, a screw thread is generated on the largest component before a keyway is produced. This measures 1.26-inches wide by 0.6-inch deep and 5.5-inches long on the Omnis VMC.

“We have been working with Ward CNC for many years, working with the applications engineering department to machine/manufacture items such as tool posts, to accompany new machine (lathe) sales,” Mr. Leonard says. “In this time, we have become familiar with the ranges of machines that Ward CNC held in stock, and when we needed CNC capacity, Ward CNC was the logical choice. The Hartford VMC was our initial installation, followed by the Hyundai-Wia SKT-300 and L300C then, most recently, the L400LMC.”

Many of the components produced on these machines are one-offs or in small batches of no more than 10 parts. However, one ongoing large contract for the volume machining of a family of axles demonstrates how the Ward CNC-supplied machines combine. Produced from EN24T billets, the axles range in size from 4-inch diameter to 11 inches long and 5-inch diameter to 24- and 37-inches long. All three sizes are turned to diameter, then, on the shortest version, a grease nipple hole is drilled and a 0.6-inch wide by 0.8-inch deep cross slot is machined by the SKT-300.

As each machine has been installed and put into service, its reliability has been noted. Subsequently, each time a CNC portfolio needed to be expanded, there was no worry about the quality of the machines or the backup from Ward CNC, nor the cost effectiveness of the packages offered.

“We ideally like to have one operator running two machines,” Mr. Leonard says. “So, commonality of CNC systems has been a factor in our choice of machines.”

As CE moves forward, it will continue to receive contracts that remain a secret to the public. Regardless, Ward CNC has proven to be a reliable supplier of machines for executing these contracts. This kind of working relationship between local shops and vendors is a pathway to a successful business. It’s borne fruit for CE, and that’s why Ward CNC is the logical choice for turning machines.

RELATED CONTENT

-

Get 5-Axis Machining on a 3-Axis VMC

Machine shops want and need to eliminate steps in the manufacturing process. Adding four- or five-axis capability to an existing three-axis VMC is a practical way to achieve five-sided machining using a single setup.

-

Selecting A VMC: Factors To Consider

A three-, four- or five-axis vertical machining center can run the gamut of capability and cost. Assessing your application requirements now and in the future can make for a much wiser machining center purchase.

-

Keeping Watch on Small Parts

From watch parts to exotic medical applications, this shop takes on the world of micromachining.