Simplifying CAD/CAM Programming

Manufacturing has come a long way since the introduction of CAD/CAM software.

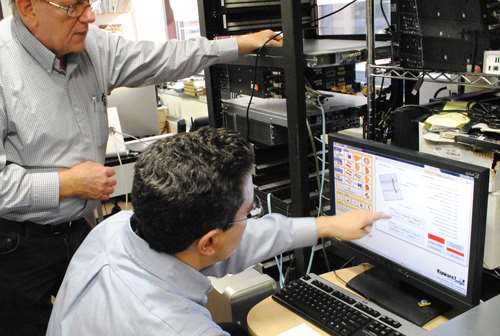

Manufacturing has come a long way since the introduction of CAD/CAM software. CAD/CAM has helped shops increase efficiencies dramatically, giving programmers the ability to quickly design complex parts and communicate the information directly to the CNC. But for a large amount of the programming that takes place in shops each day, the complex capabilities of a typical CAD/CAM package may be considerably more than is needed, potentially slowing down the programming process and restricting the work capacity of good chipmakers who don’t happen to be proficient with the software.

Easier to Understand

Kentech Inc. offers KipwareT (for turning applications) and KipwareM (for milling applications) conversational software to assist users quickly and efficiently with creating simpler, everyday programs for turning, boring, grooving and threading. The term “conversational” is used in the product name to describe the use of simple fill-in-the-blank forms to create G-code programs for a series of standard machining shapes and operations such as bar feeding, turning, boring, OD and ID grooving and threading, short and deep hole drilling, tapping and more.

Featured Content

By completing the fields in the fill-in-the-blank form, the user describes the shape in the machining operations. Roughing and finishing, along with corner breaks, chamfering or rounding, can be created with the click of a button. Grooving programs can be created for simple or complex grooves with user-defined side angles. Threading menus create simple or complex thread cutting with multiple angles. No drawing or drawing experience is required.

Optional live tool programming can create G-code programs for live tools using the conversational screens. Operations include drilling and milling along both the X and the Z axis. For shapes that don’t fall into the standard category, Kipware Conversational comes with a CAD-like sketch pad. By either drawing the tool path directly or importing a DXF file, users can create G-code programs for non-standard shapes. The sketch pad is an intuitive drawing package that will perform calculation of tangencies and intersecting lines automatically. Once the tool path is drawn, operators can use a conversational menu to describe the machining parameters and create the G-code program. Programming for canned cycles and cutter comp are also included.

The software is designed to allow users to create each machining operation to complete the total machining of the workpiece. Each time an operation is programmed through a conversational screen or the sketch pad, it is added to the tree. These operations can then be brought back into the conversational screen at any time for editing. In addition, users can take previously created cycles, add them to the tree, bring them into the conversational screen and make any changes, and create completely new cycles. Still, no G-code programming is required.

Once all the operations are created, users can use the main program feature to link them together with tools and related calls, and then create the complete G-code program. Once complete, the G-code program is displayed in the G-code editor.

While operations are being created, the optional Kipware TP toolpath plotting application can display the tool path on the screen. Users can plot individual cycles or all of the operations in the tree. Kipware TP is a full G-code editor and toolpath plotting application with an assortment of real world shopfloor features.

Added Features

The most recent version of the software uses Microsoft’s .NET Version 4 framework for an improved user interface. This interface features an enhanced text editor that is G-code specific and can be used to edit any G-code, including that produced outside of Kipware.

Because the software is PC-based, and not CNC-control based, it allows conversational CNC programming to take full advantage of the power of the PC, while not being limited by the CNC control environment.

Using KipwareM, operators can have any cycles that are created in the conversational menus (including text and engraving) auto-rotated to any user-defined angle by entering the angle into the rotation field.

Users can load previously created cycles from a disk, edit them in the conversational menus, copy them, and use them to create completely new cycles. These features mean faster and less redundant programming for items such as family of parts or recurring shapes and features.

Cutting direction is user-defined for milling and turning. Users can select CW or CCW cutting for all milling cycles and can elect turning or facing for turning cycles. Individual directions can be selected for both roughing and finishing. And all roughing and finishing operations can be programmed from a single menu.

The addition of Kipware Conversational allows shops to focus their CAD/CAM personnel on the more complex workpieces while machine operators can quickly perform the simpler, everyday programming. With shops finding a shortage of skilled metalworking and CAD/CAM personnel, use of this software could potentially ease the programming burden and increase work flow.

RELATED CONTENT

-

Optimizing B Axis on Gang Tool-Based Swiss Machines

This technological innovation has been increasing in popularity as well as multitasking sophistication.

-

How to Get More Efficient Production from Swiss-Type and Multitasking Machines

SolidCAM for multi-axis Swiss type and multitasking machines provides a very efficient CAM programming process, generating optimal and safe Mill-Turn programs, with dramatically improved milling tool life.

-

Automate Programming with CAM

Even for those shops still manually programming their simple parts on Swiss machines, there are compelling reasons to automate the programming process now.